Drainage system for fluid filter

A fluid filter and discharge system technology, applied in the field of discharge systems, can solve the problems of high manufacturing cost, high failure frequency and uncontrolled discharge system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

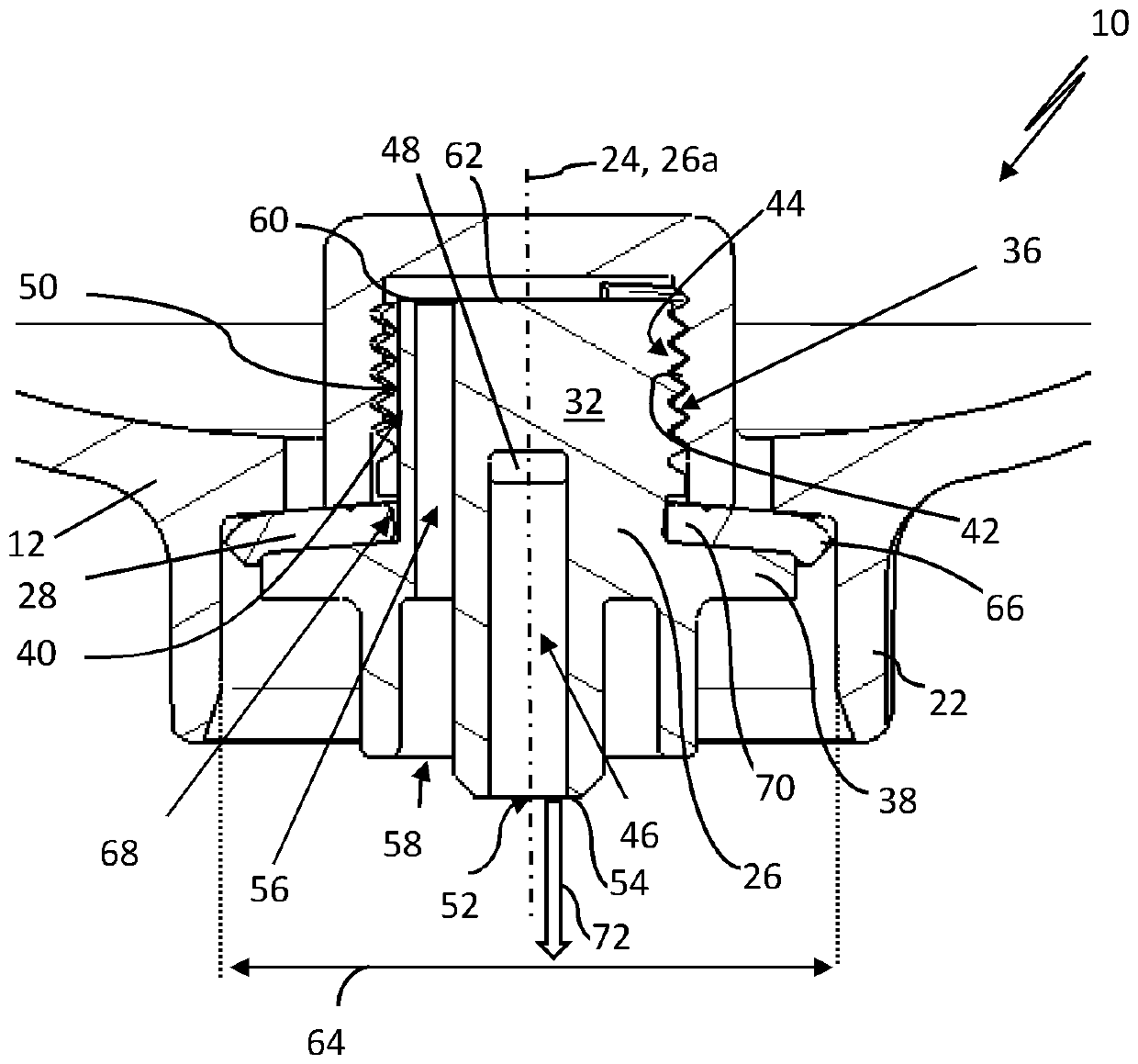

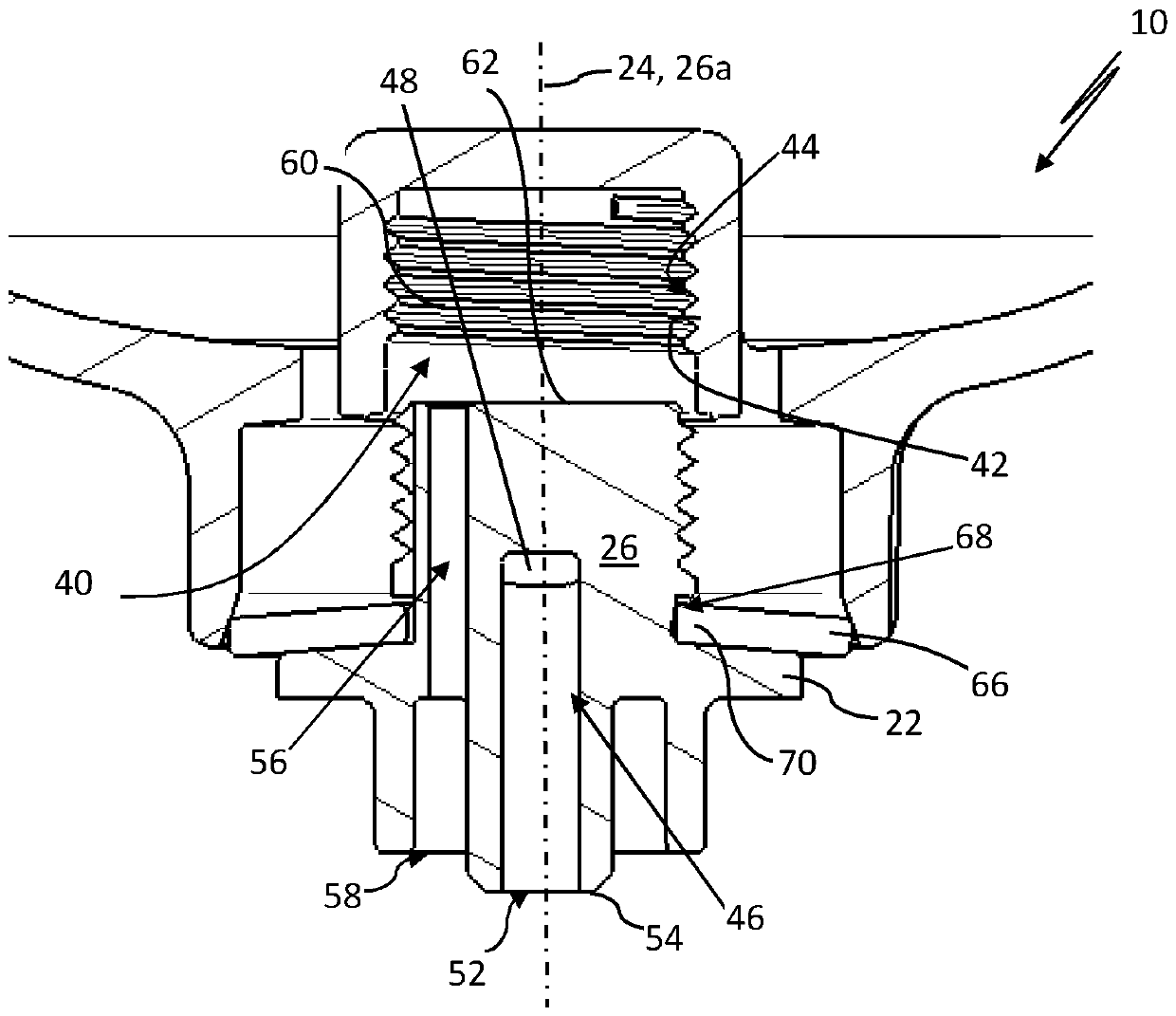

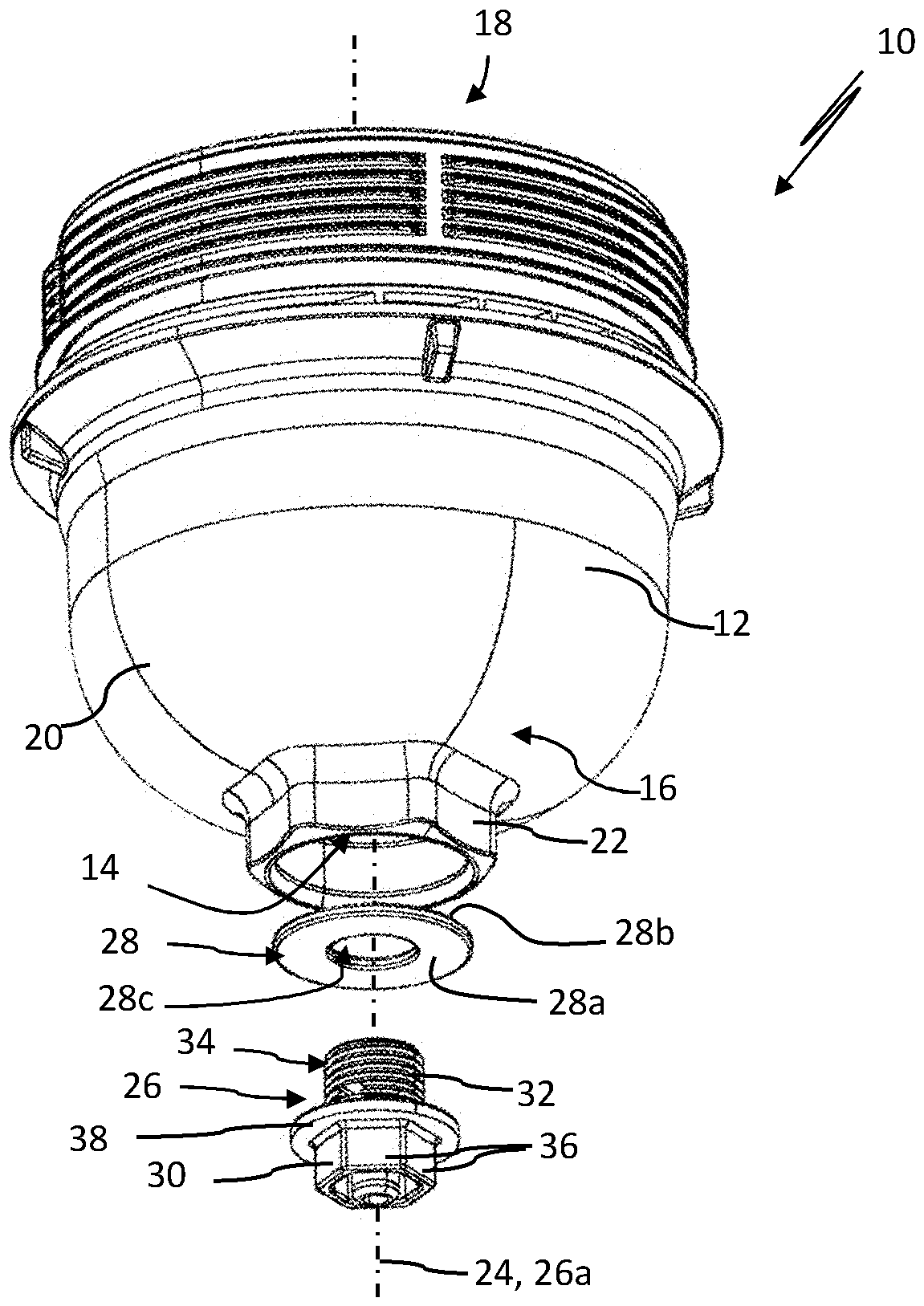

[0026] figure 1 A perspective view of a drain system 10 for fluid, in particular for draining water from the water reservoir of an oil filter or fuel filter, is shown.

[0027] The exhaust system 10 comprises a filter housing element 12, which may be formed, for example, as a housing bowl or a housing cover of a filter housing, for eg mounting a filter element (not shown) therein. The housing element 12 is provided at its lower end 16 with a drain hole 14 for connecting the inner side 18 of the filter housing element 12 with the outer side 20 of the filter housing element 12 . On the lower end 16 of the housing element 12 a spout or collar 22 is provided. The collar 22 may protrude from the lower end 16 of the housing element 12 in an axial direction relative to the longitudinal axis 24 of the housing element 12 . Alternatively, the collar 22 can also project obliquely, in particular orthogonally, from the housing element 12 with respect to the longitudinal axis 24 of the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com