Automatic cleaning instrument of capillary viscometers

A capillary viscometer and automatic cleaning technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

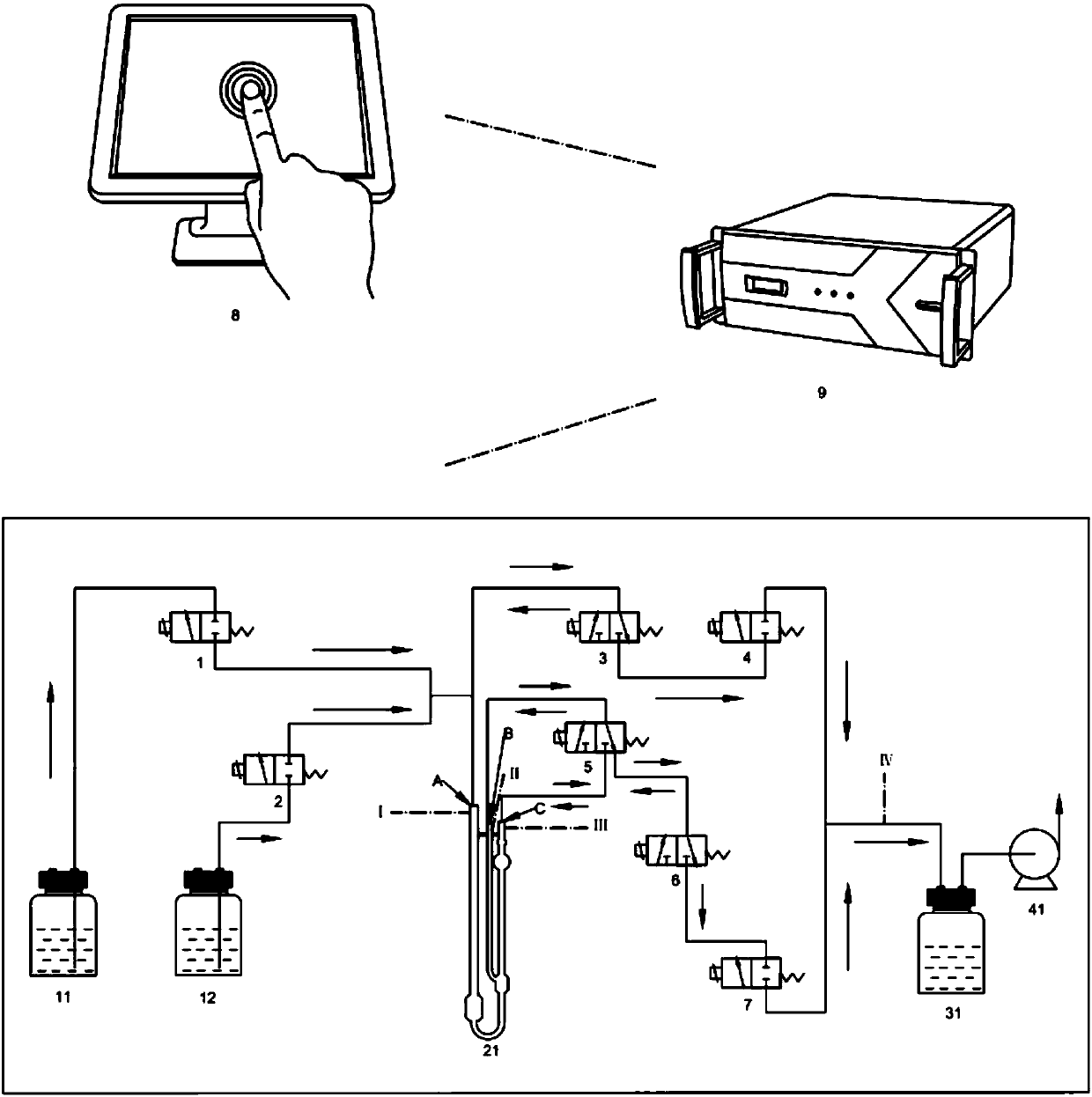

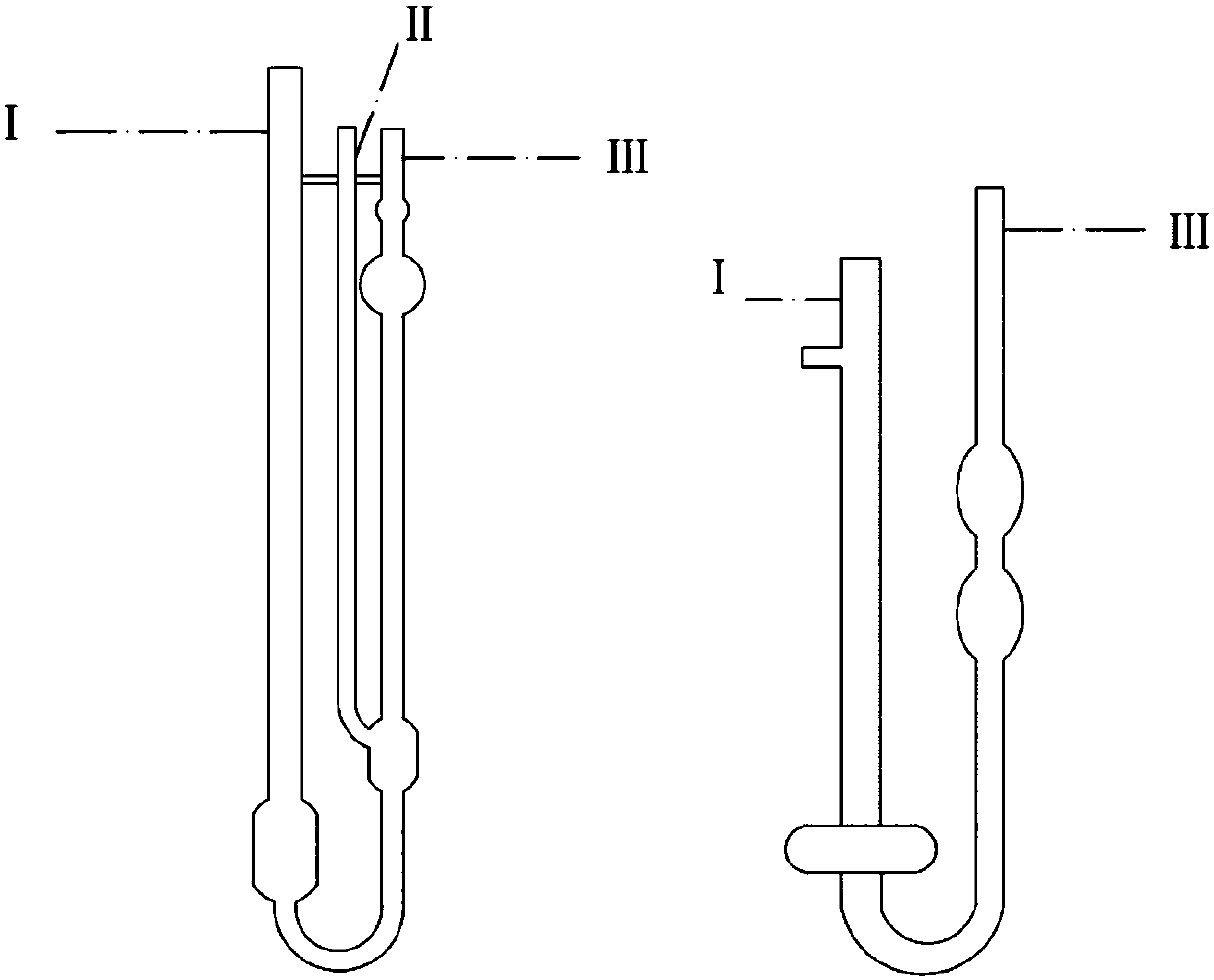

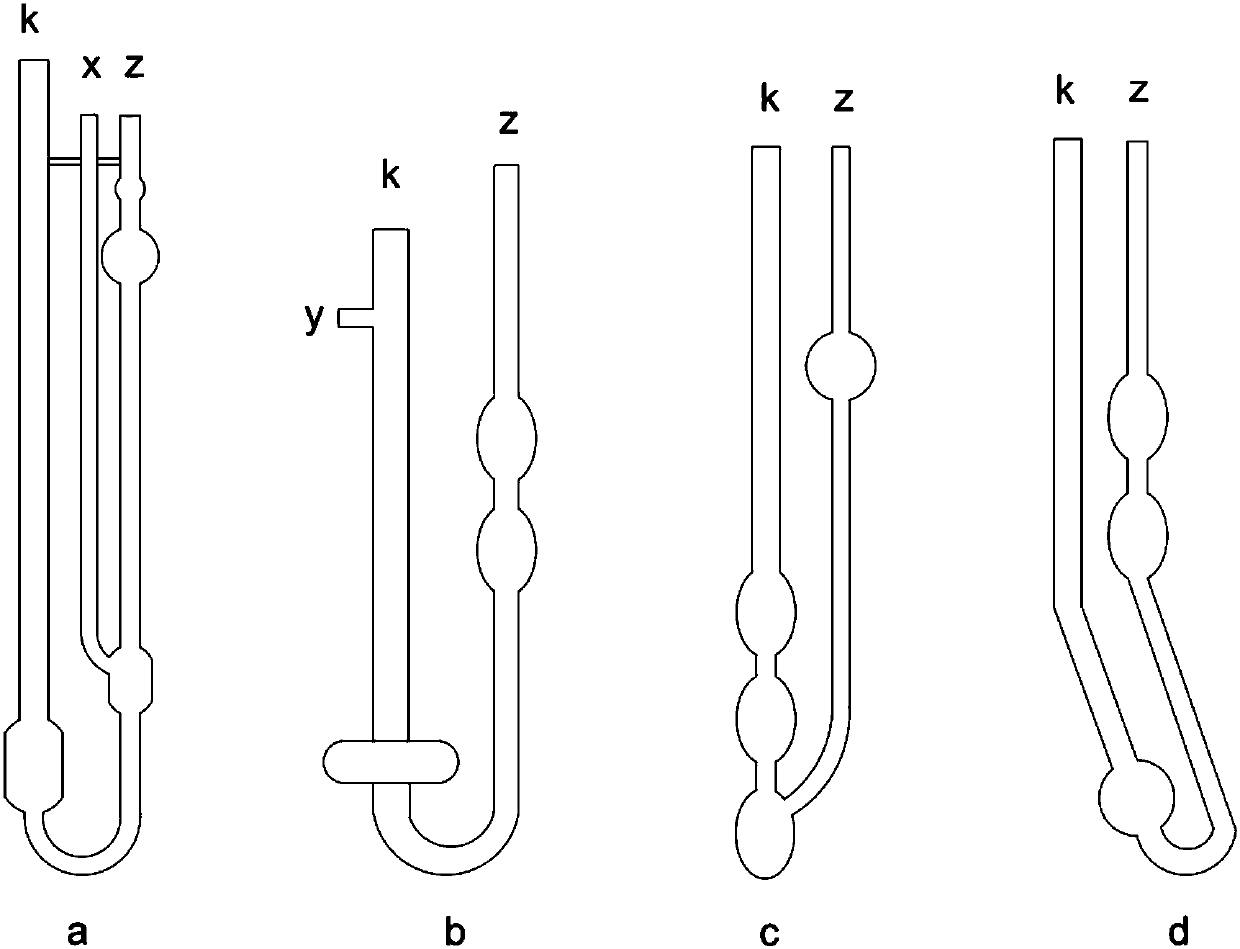

[0048] Clean the Ubbelohde viscometer: connect the wide pipe, side pipe and main pipe of the viscometer to joints A, B and C respectively. Please refer to the attached figure 1 .

[0049] Use petroleum ether only for cleaning (fill reservoir 11 with petroleum ether):

[0050] Clean the wide pipe and side pipe first:

[0051] (1) Inject solvent petroleum ether: After the program controller issues a cleaning command, solenoid valves 1 and 7 are energized and connected; solenoid valves 3 and 6 are energized and connected to the liquid circuit; solenoid valves 2 and 4 are disconnected; solenoid valve 5 is in a power-off state , the side pipe is connected to the pipeline; the vacuum pump 41 is turned on. A proper amount of petroleum ether is sucked out from the liquid storage tank 11 by negative pressure, and sucked into the side pipe through the wide pipe. When the liquid level rises to 1cm below the top of the side pipe, the sensor II receives a signal, and the solenoid valve...

Embodiment 2

[0093] Clean the Pingshi viscometer: connect the viscometer wide pipe, branch pipe, and main pipe to joints A, B, and C respectively.

[0094] Cleaning with petrol only (fill tank 11 with petrol):

[0095] Cleaning of wide pipes and main pipes:

[0096] (25) Injecting solvent gasoline: After the program controller sends out the cleaning instruction, the solenoid valves 1 and 7 are energized and connected; the solenoid valves 3 and 6 are energized and connected to the liquid circuit; , 4 are disconnected; the vacuum pump 41 is turned on. Utilize the negative pressure to suck out a proper amount of gasoline from the liquid storage tank 11, and inhale the main pipe through the wide pipe. When the liquid level rises to 1cm below the top of the main pipe, the sensor III receives a signal, and the solenoid valves 1 and 7 are disconnected after a delay of 0.1s, the vacuum pump 41 is turned off, and the solvent feeding process ends.

[0097] (26) Gasoline hovering and soaking in th...

Embodiment 3

[0124] Clean the countercurrent viscometer: connect the wide tube and main pipe of the viscometer to joints A and C respectively.

[0125] Cleaning with petrol only (fill tank 11 with petrol):

[0126] Cleaning of wide pipes and main pipes:

[0127](43) Injecting solvent gasoline: After the program controller issues a cleaning instruction, solenoid valves 1 and 7 are energized and connected; solenoid valves 3 and 6 are energized and connected to the liquid circuit; , 4 are disconnected; the vacuum pump 41 is turned on. Utilize the negative pressure to suck out a proper amount of gasoline from the liquid storage tank 11, and inhale the main pipe through the wide pipe. When the liquid level rises to 1cm below the top of the main pipe, the sensor III receives a signal, and the solenoid valves 1 and 7 are disconnected after a delay of 0.1s, the vacuum pump 41 is turned off, and the solvent feeding process ends.

[0128] (44) Gasoline hovering and soaking in the main tube: After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com