Lubricating grease subpackage device

A lubricating grease and subpackaging technology, which is applied in the field of lubricating grease, can solve problems affecting product appearance and quality, heavy labor workload, grease pollution, etc., and achieve the effects of manpower saving, high work efficiency, and accurate weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

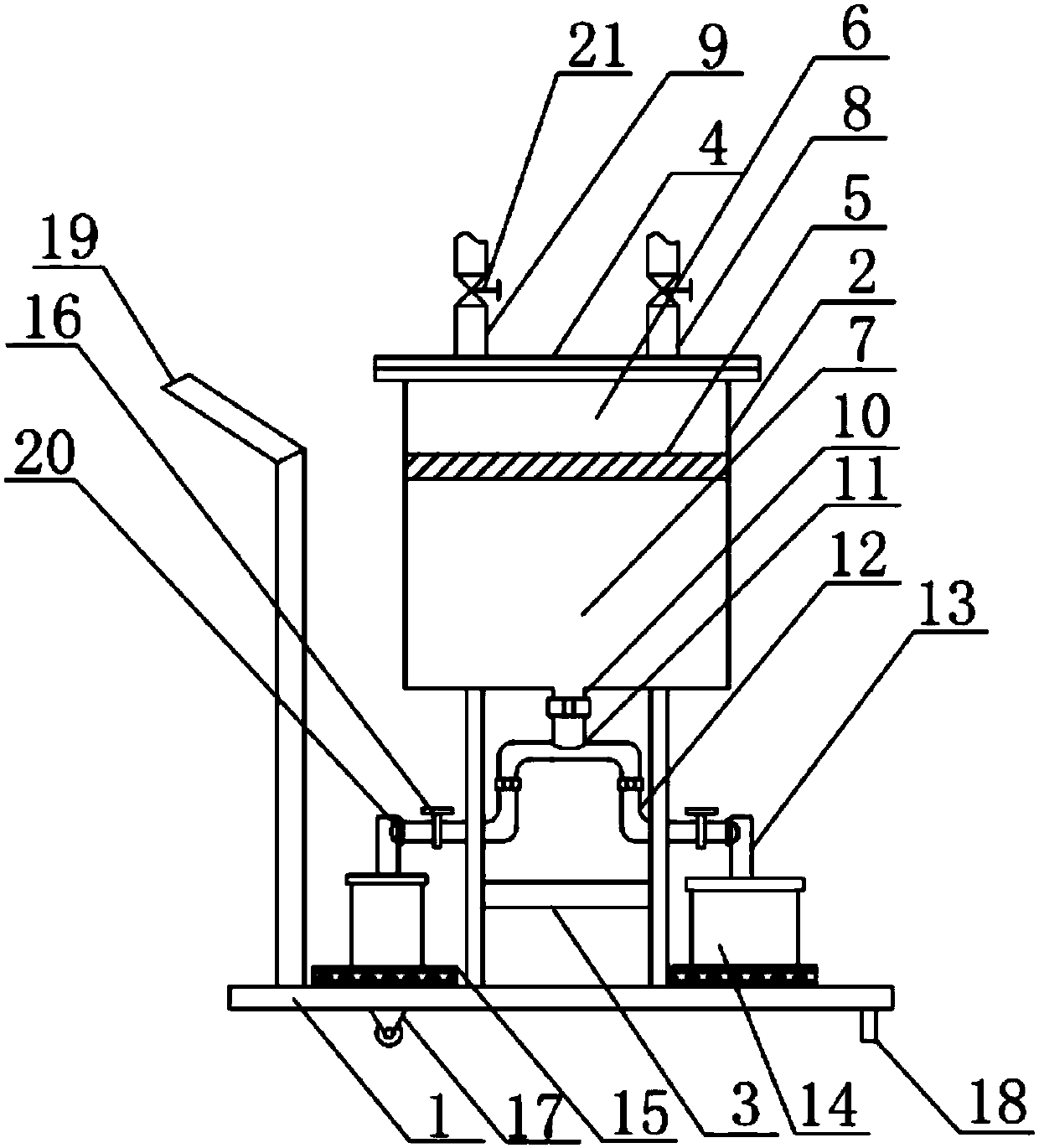

[0024] Such as figure 1 As shown, a grease dispensing device of the present invention includes a fixed frame 1 and a grease storage tank 2, the grease storage tank 2 is fixed on the fixed frame 1 through a support frame 3, and the grease storage tank 2 is a sealed structure, A detachable sealing cover 4 is installed on the top of the grease storage tank 2, and a sealed piston 5 is installed horizontally inside the grease storage tank 2, and the piston 5 separates the inner cavity of the grease storage tank 2 into an upper air chamber 6 and a lower oil storage chamber. chamber 7, the top of the fat storage tank 2 is provided with an exhaust pipe 8 communicating with the air chamber 6 and an air intake pipe 9 externally connected to compressed gas, and the bottom of the oil storage chamber 7 is provided with a fat outlet 10, and the fat outlet The port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com