Icebreaking device

An ice-breaking and action-based technology, which is applied in snow surface cleaning, construction, cleaning methods, etc., can solve the problems affecting the use of personnel and equipment life, low efficiency of road cleaning, and inability to clean roads, etc., to achieve flexible and convenient layout and application, and good ice-breaking effect , the effect of vibration reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

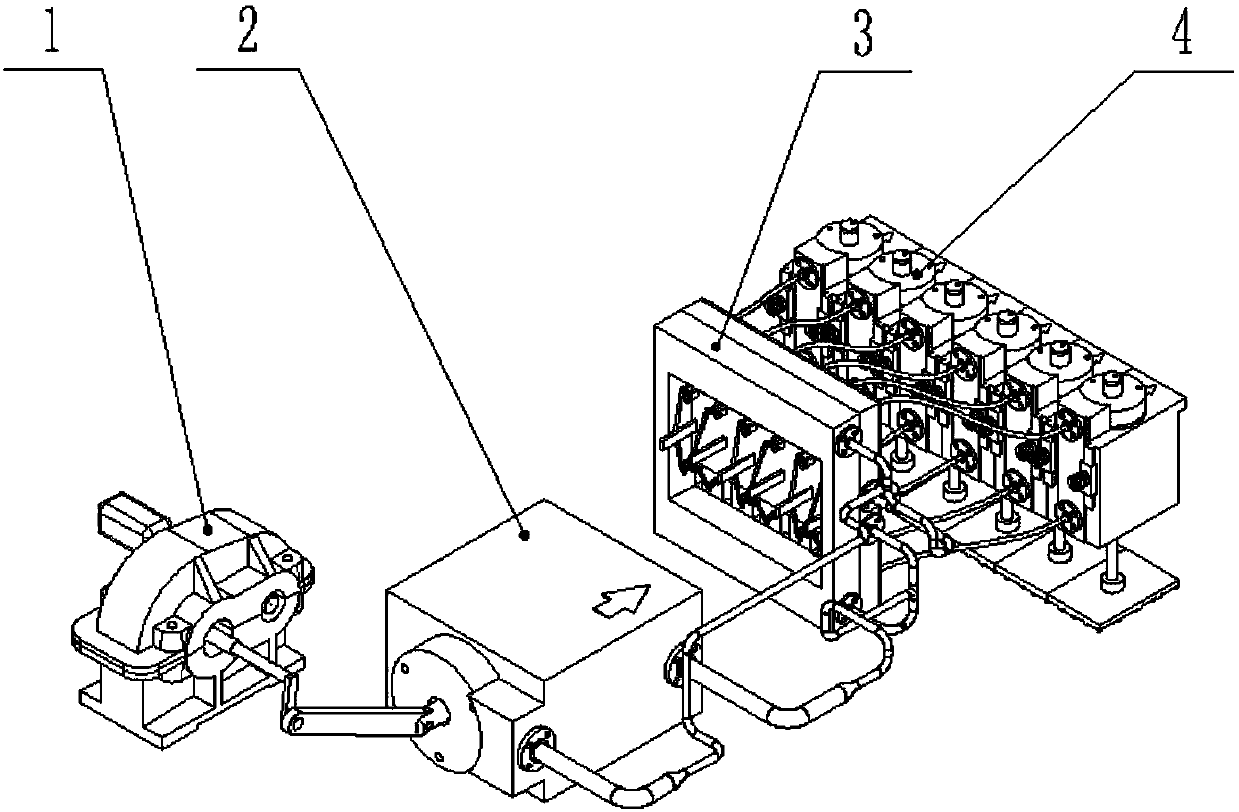

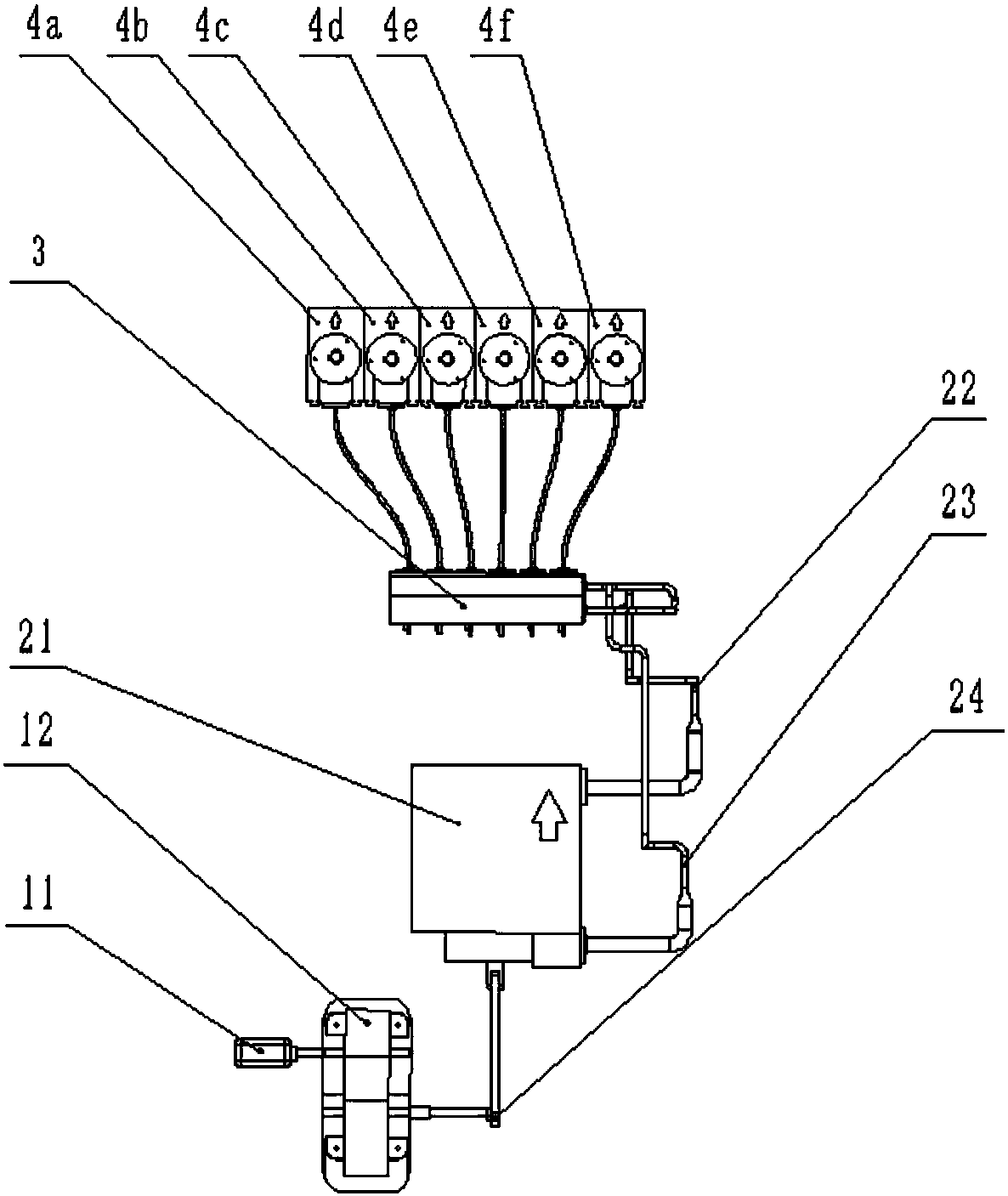

[0051] figure 1 and figure 2 An ice-breaking device is shown, including a power part 1 , a cycle pressurization part 2 , a control switch part 3 and an ice-breaking action module 4 .

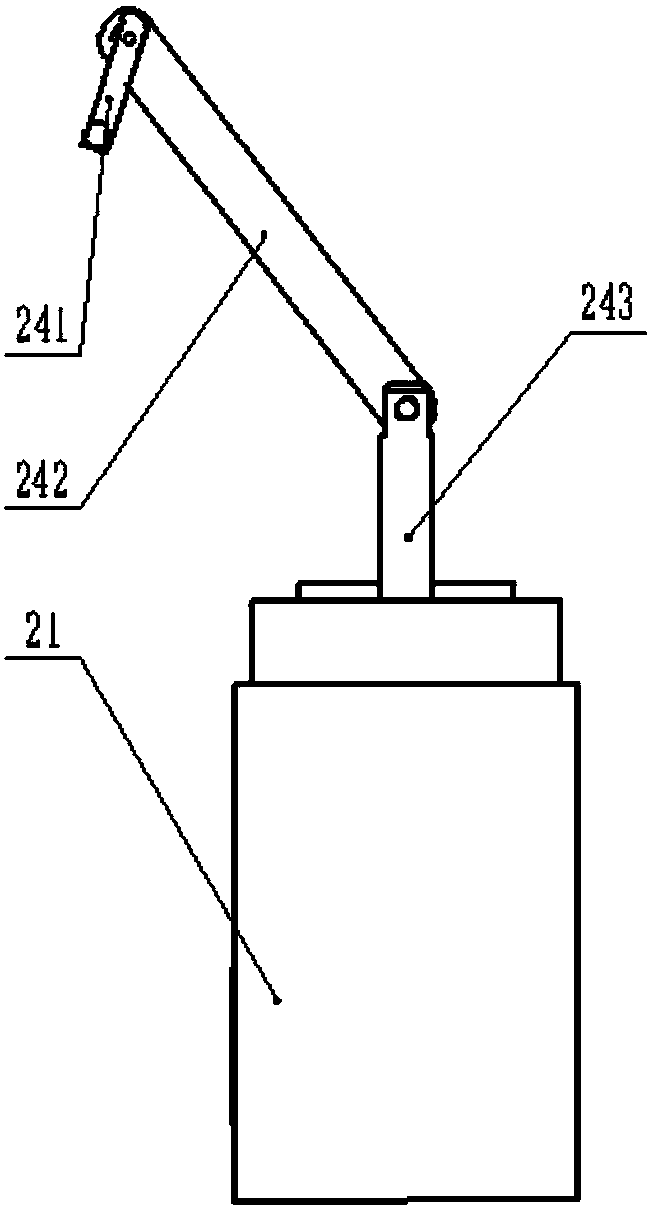

[0052] The power unit 1 includes a servo motor 11 and a reducer 12, the power unit 1 is connected to the link mechanism 24 of the circulating pressurization unit 2, and the link mechanism 24 converts the rotational movement of the power unit 1 into pressurization Reciprocating motion with short stroke time and long return stroke time. The cyclic pressurizing part 2 is flexibly connected with the ice-breaking action module 4 through the air circuit of the control switch part 3 .

[0053] The circulation pressurization cylinder 21 is fixedly installed on the carrier. When pressurizing, the pressure is transmitted through the pressure conduit 23 , and the gas in the ice-breaking action module flows back to the circulation pressurization cylinder 21 through the low pressure conduit 22 . The ice-...

Embodiment 2

[0085] like Figure 7 The ice-breaking action module shown is connected to the carrier through the elastic suspension device 47, and the ice-breaking action module can also be driven by hydraulic pressure, and the hydraulic pipe is a flexible pipe. The upper part of the piston 43 has a first elastic component. When the ice breaking device works, it has little impact on the carrier and its own vibration is also small.

[0086] ice breaker

[0087] like Figure 8 In the shown ice-breaking board, the blades are arranged in a network of diamond-shaped holes, covering the entire width of the ice-breaking board. The blade can be an integrally formed whole mesh; it can also be sporadic with each edge being a blade, which is bonded and spliced; or each rhombus can be an integrally formed blade, which is spliced into a mesh.

[0088] like Figure 9 As shown in the sectional view of the ice breaking board, the ice breaking board includes a base plate 52 made of light material a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com