Factory waste heat utilization system

A waste heat, factory technology, applied in waste heat treatment, lighting and heating equipment, process efficiency improvement and other directions, can solve the problems of heat waste, limited thermal insulation effect, can not be effectively used, etc., to achieve the effect of efficient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

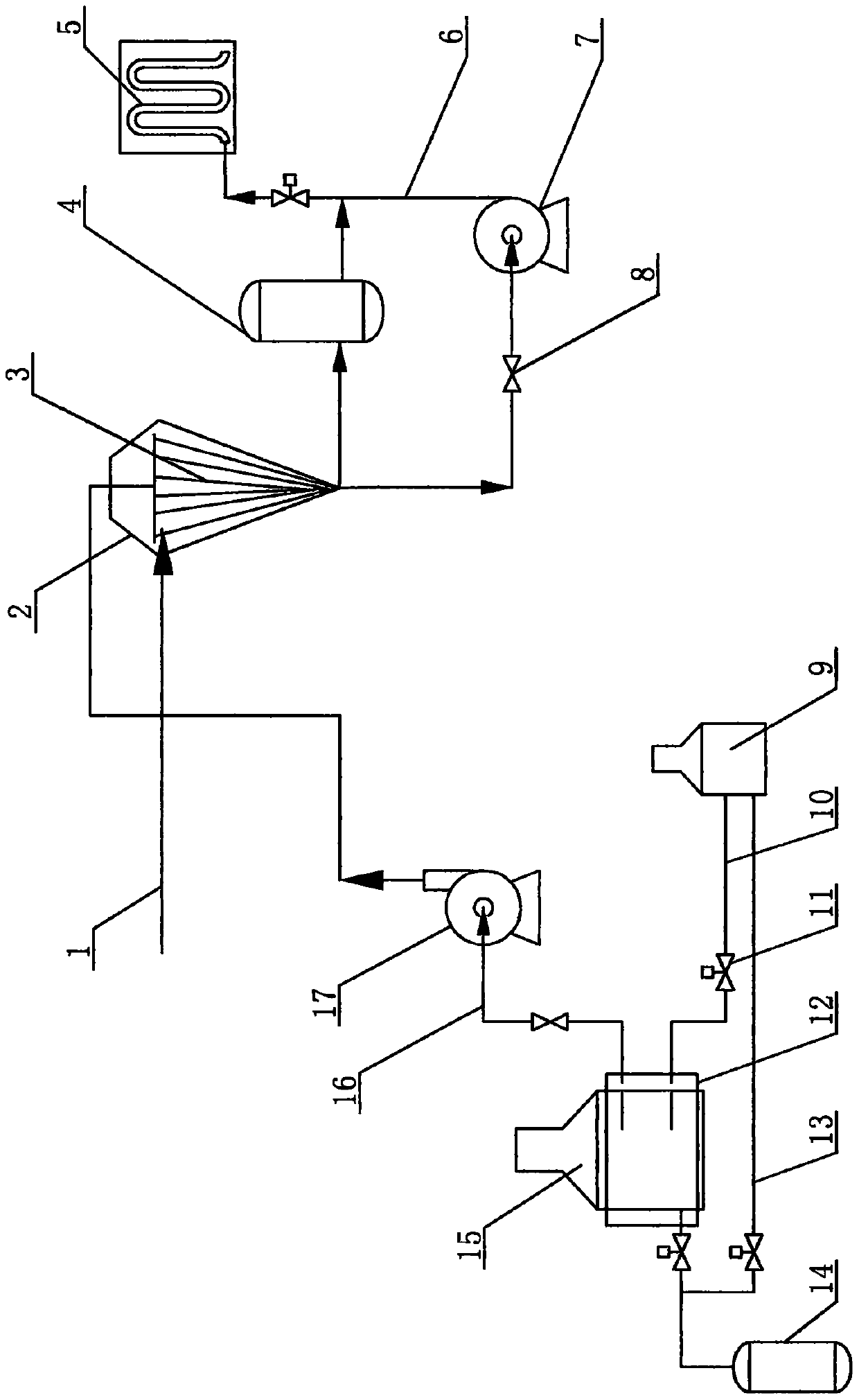

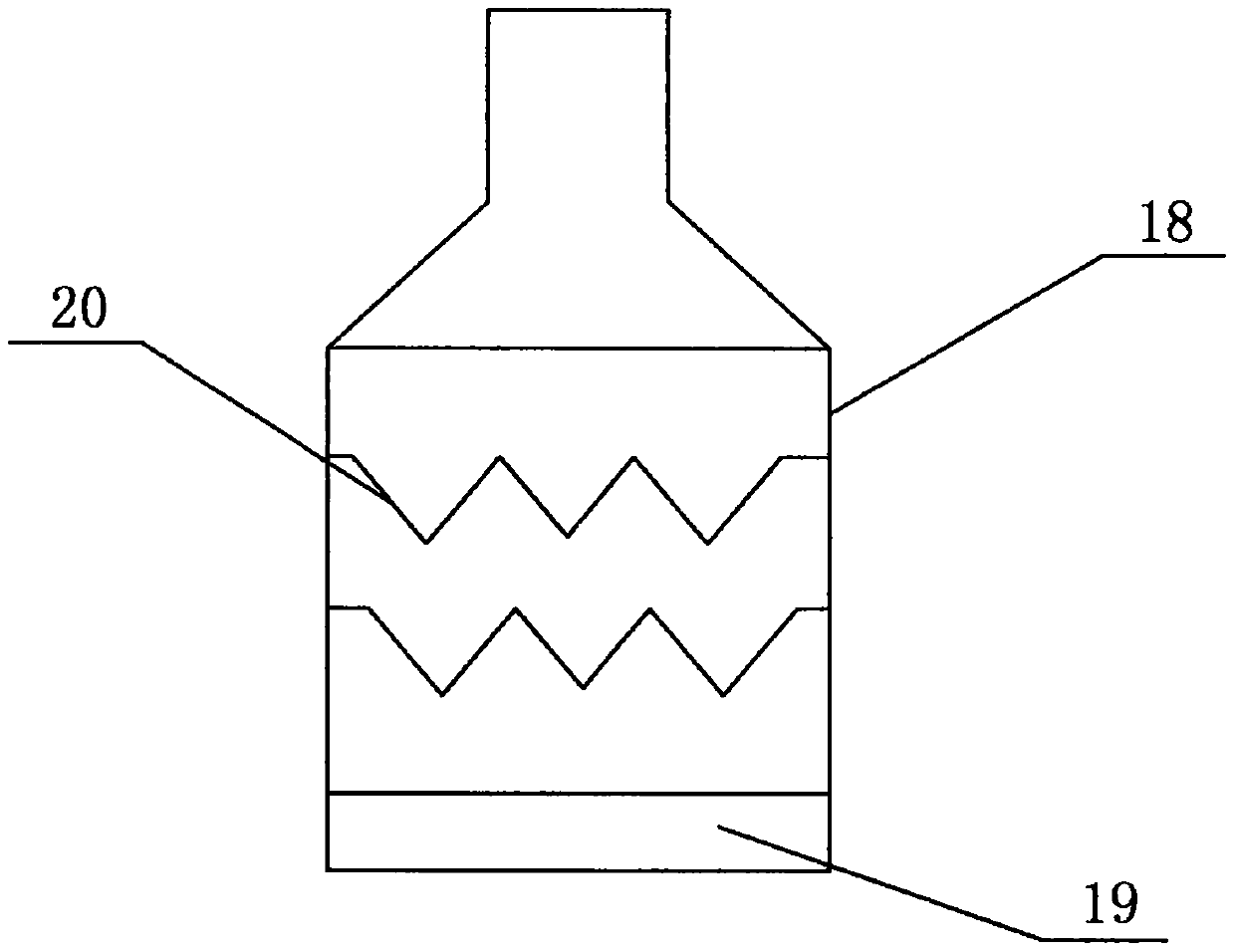

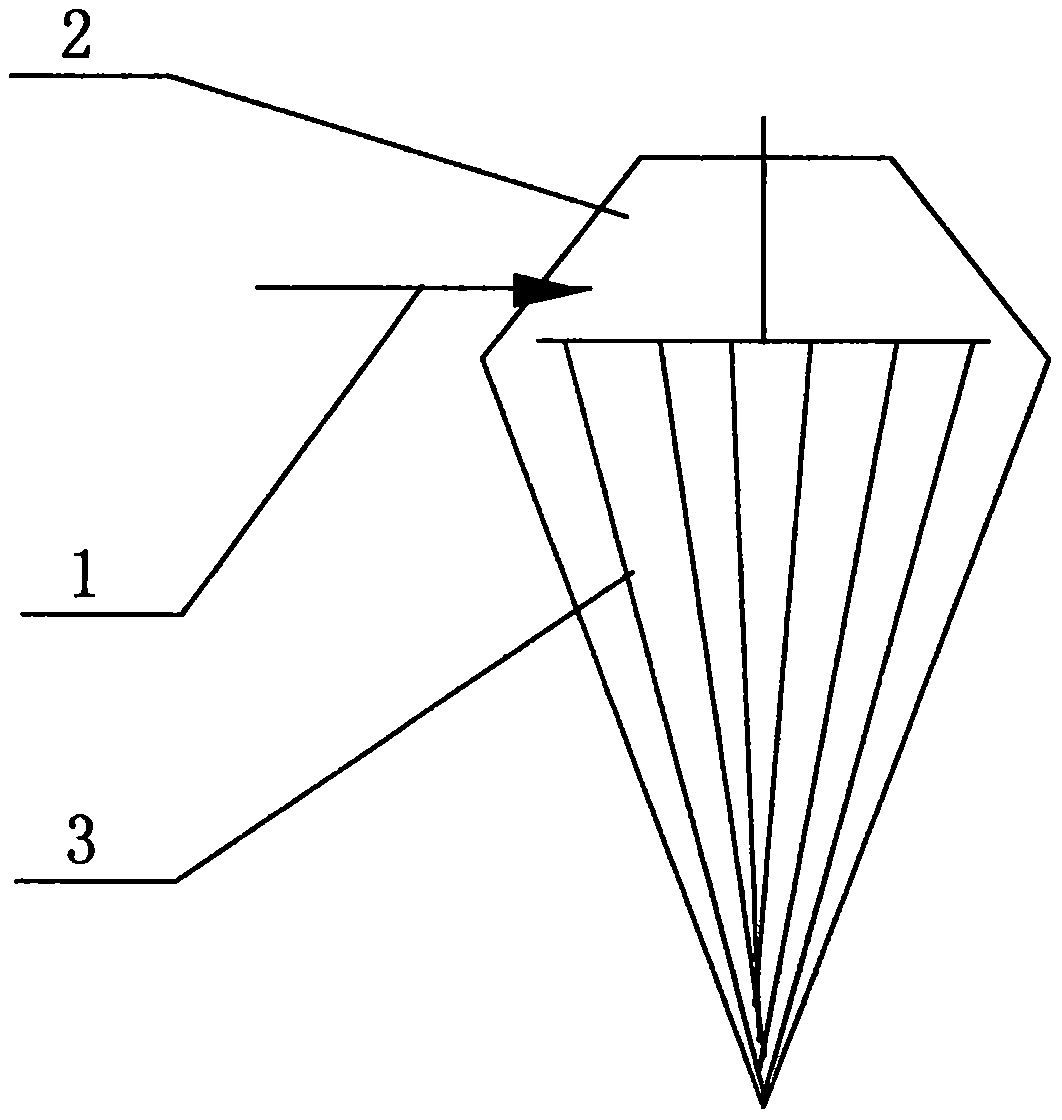

[0017] Such as Figure 1-2 As shown, the plant waste heat utilization system of the present invention includes a gas storage tank 14 and a kiln 15, and the outside of the kiln 15 is provided with a heat collecting cover 12, and the heat collecting cover 12 is respectively connected to the first hot gas pipe 16 and the second heat pipe 16. Air pipe 10, the air outlet of the first hot air pipe 16 is connected with the air intake coil 3, and the pipeline between the first hot air pipe 16 and the air intake coil 3 is provided with a stop valve 8 and an exhaust fan 17 successively, and the air intake disk The outside of the pipe 3 is provided with a water tank 2, the air outlet of the intake coil 3 is connected to the condensation tank 4, the water outlet of the condensation tank 4 is connected to the radiator 5, and the pipeline between the condensation tank 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com