Leakage measurement system

A technology of leak detection and test head, applied in the field of detection, can solve the problem of not having seals and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

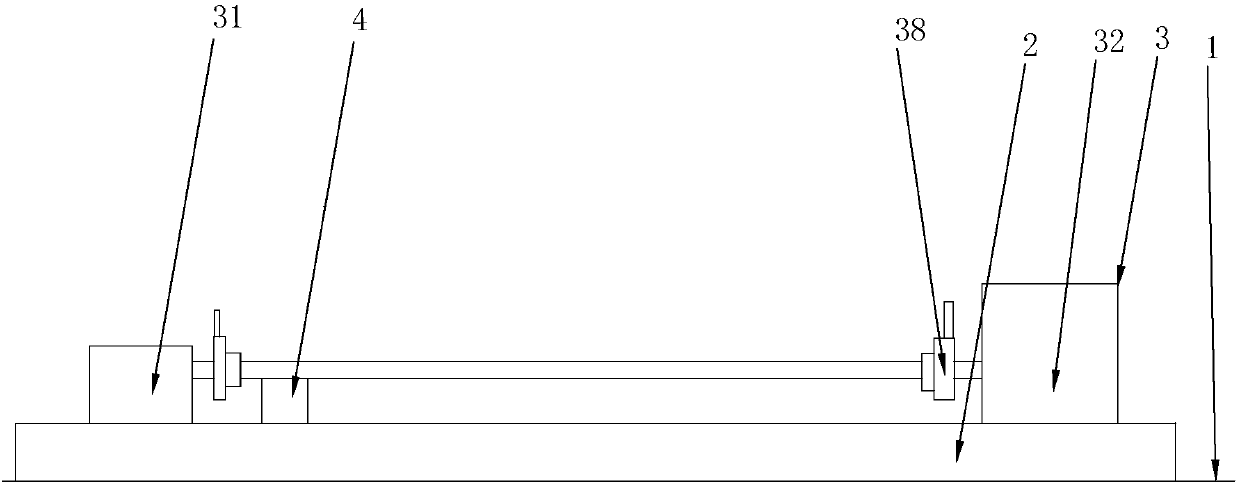

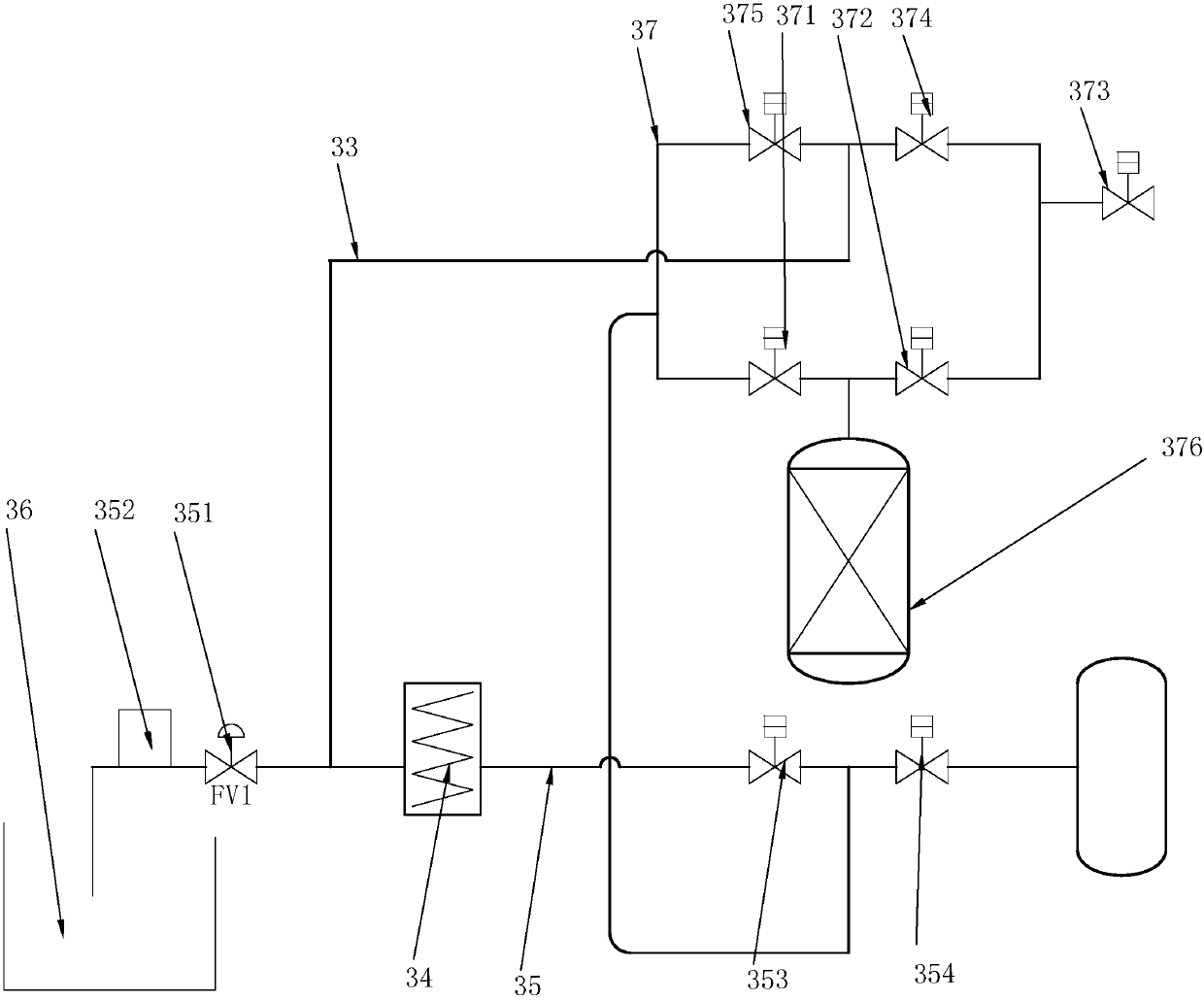

[0018] see Figure 1 to Figure 3 , a leak detection system of the present invention, comprising a workbench 1, a debugging stand 2 installed on the workbench 1 and a test group 3 slidably installed on the debugging stand 2, the debugging stand 2 is provided with a The clamping group 4, the test group 3 is provided with a first test head 31 and a second test head 32, the first test head 31 and the second test head 32 can respectively clamp the two ends of the product, the first The test head 31 and the second test head 32 are slidably arranged at both ends of the debugging frame 2, and the first test head 31 and the second test head 32 are connected to the water control group 33 respectively, and the water control group 33 is used for Test and inspect products.

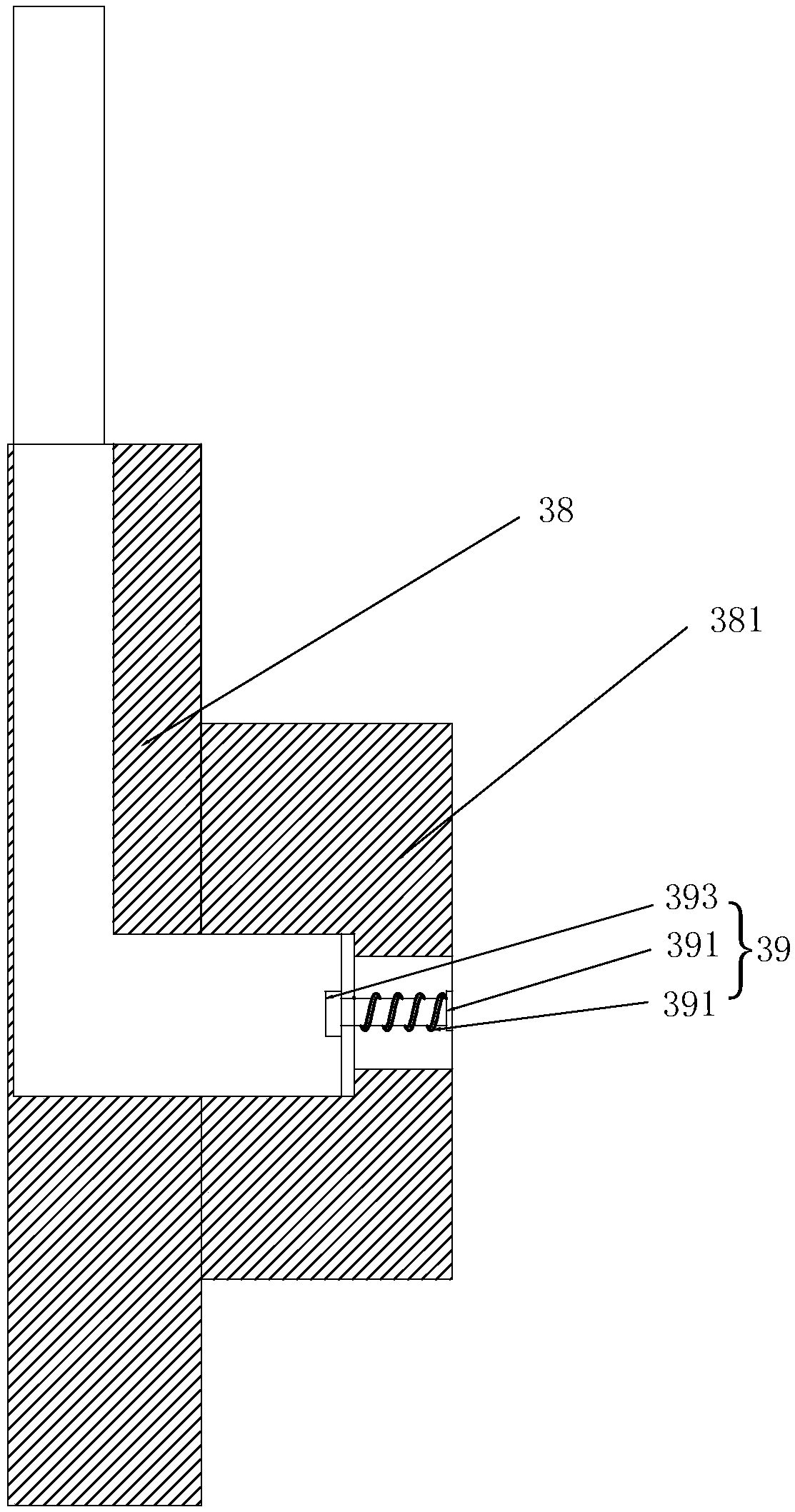

[0019] see figure 1 and image 3 , the first test head 31 and the second test head 32 are provided with telescopic cylinders, and the cylinders are provided with joints 38 for connecting products. One end of the jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com