Nuclear power station safety-class output control circuit test method and system

A technology of output control and loop test, which is applied in nuclear power generation, nuclear engineering, nuclear reactor monitoring, etc., can solve the problems of safety risks and misoperation of on-site drive equipment, and achieve the effects of avoiding risk problems, improving load capacity, and avoiding false starts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

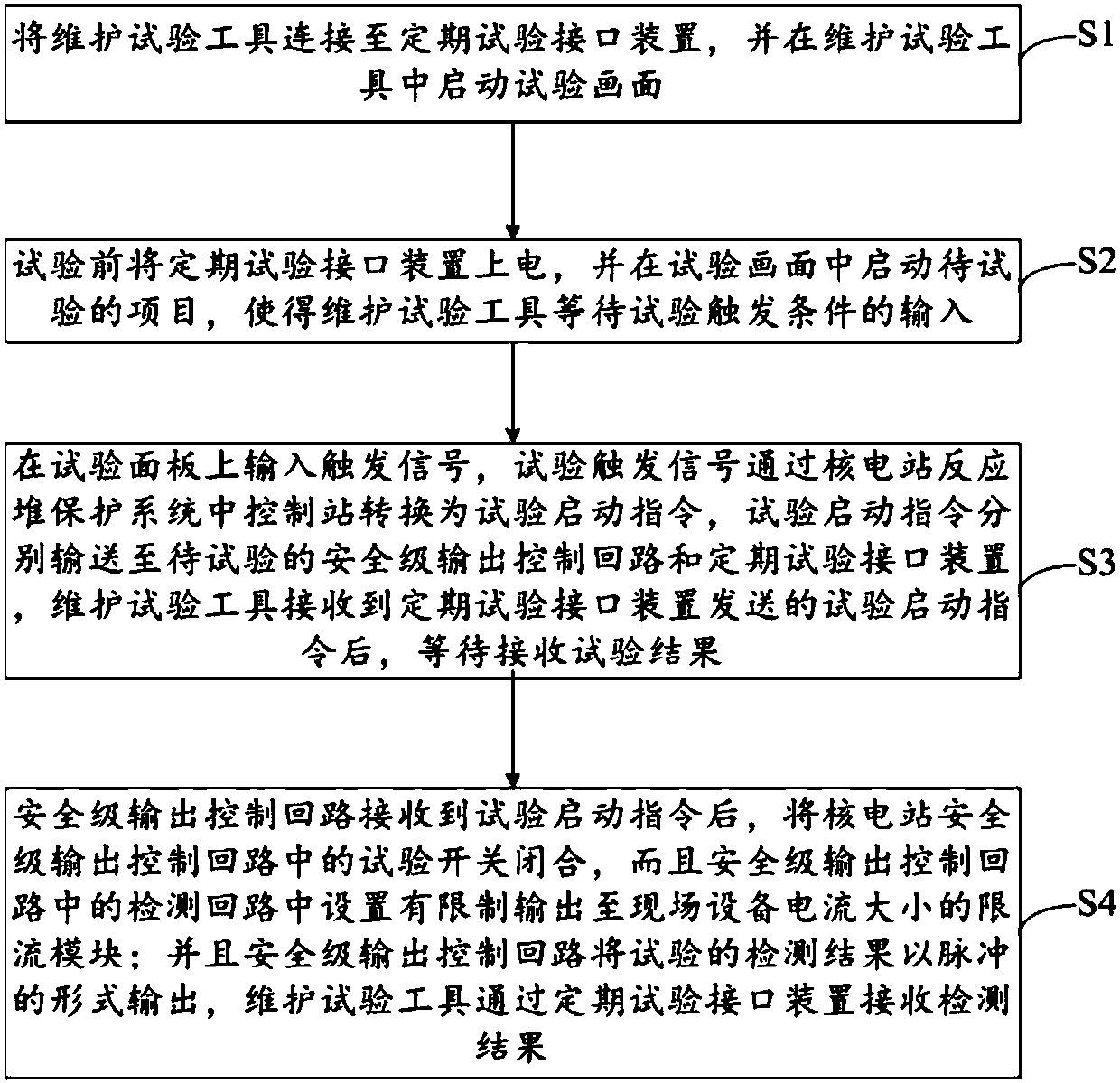

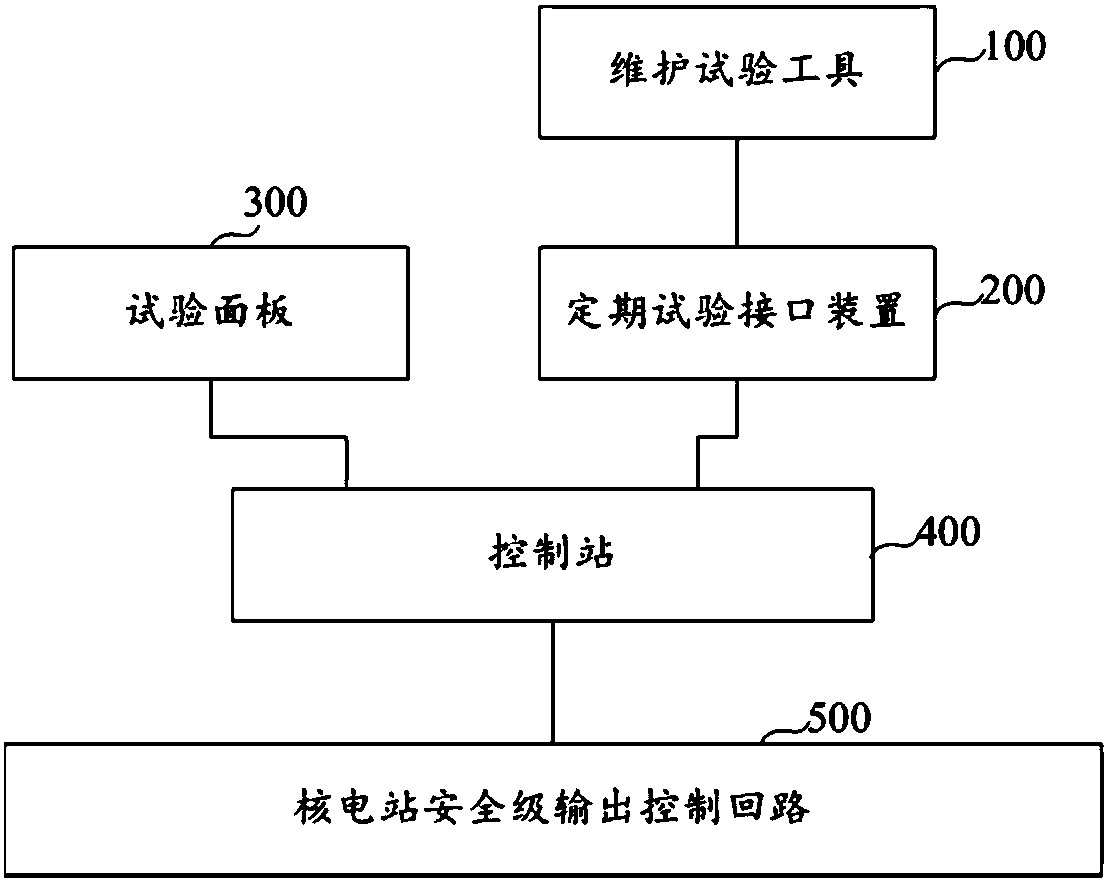

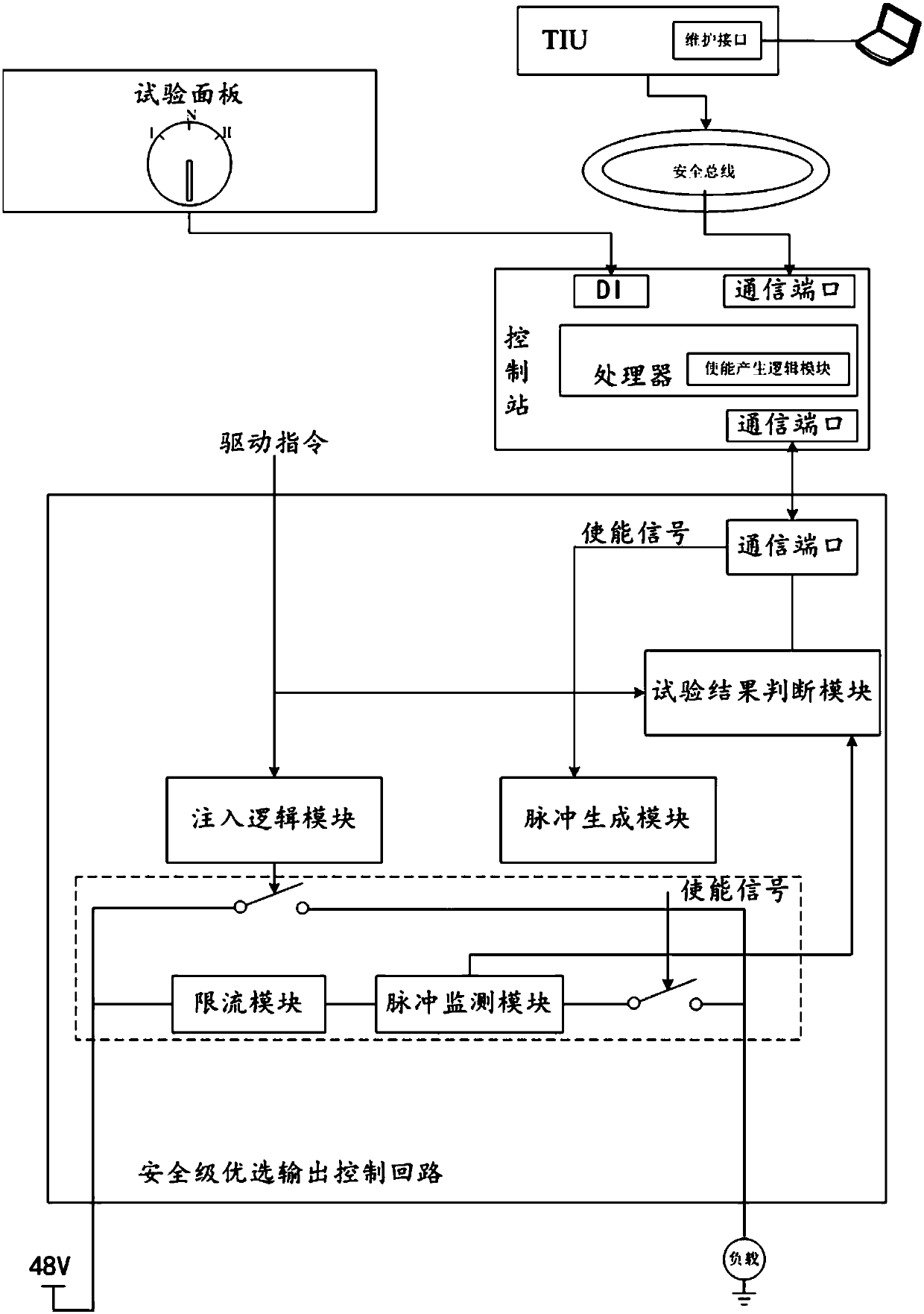

[0042] Such as figure 1 As shown, this embodiment provides a test method for the safety level output control loop of a nuclear power plant, the test method includes:

[0043] S1. Connect the maintenance test tool to the periodic test interface unit (hereinafter also referred to as TIU, or special test equipment), and start the test screen in the maintenance test tool; wherein, the maintenance test tool can be but not limited to be set in the computer for recording The application tool for the safety level output control loop test process of the nuclear power plant, and the screen for recording the test data and the test process is set in the maintenance test tool, and the screen is a screen displayed by a computer; During the test, the periodic test interface device is not charged;

[0044] S2. Power on the periodic test interface device before the test, and start the item to be tested in the test screen, so that the maintenance test tool waits for the input of the test trigg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com