Multi-time programmable (MTP) device and manufacturing method thereof

A manufacturing method and device technology, applied in the field of multiple programmable devices and MTP device manufacturing, can solve problems such as insufficient process margin, insufficient efficiency, and MTP test failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

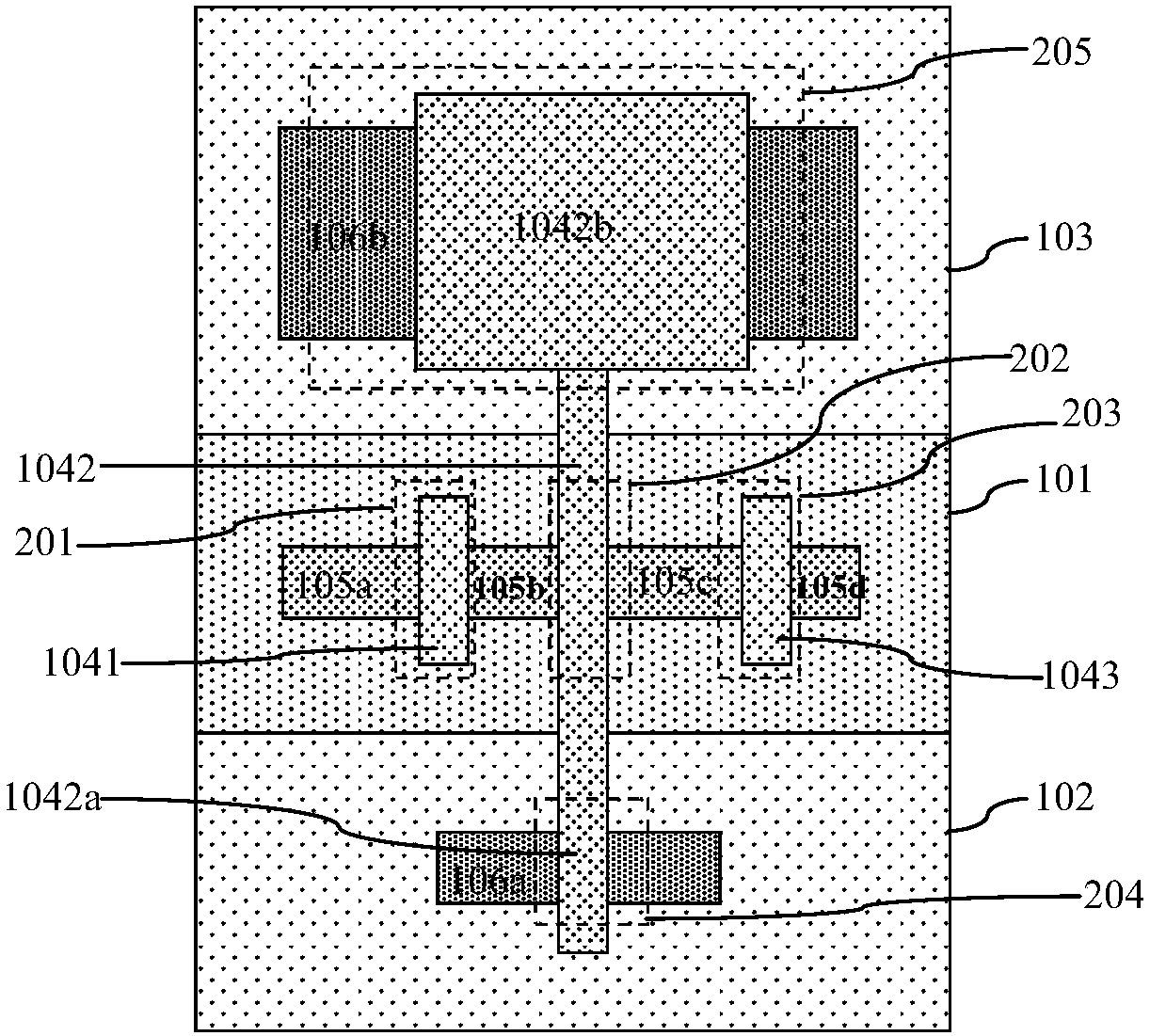

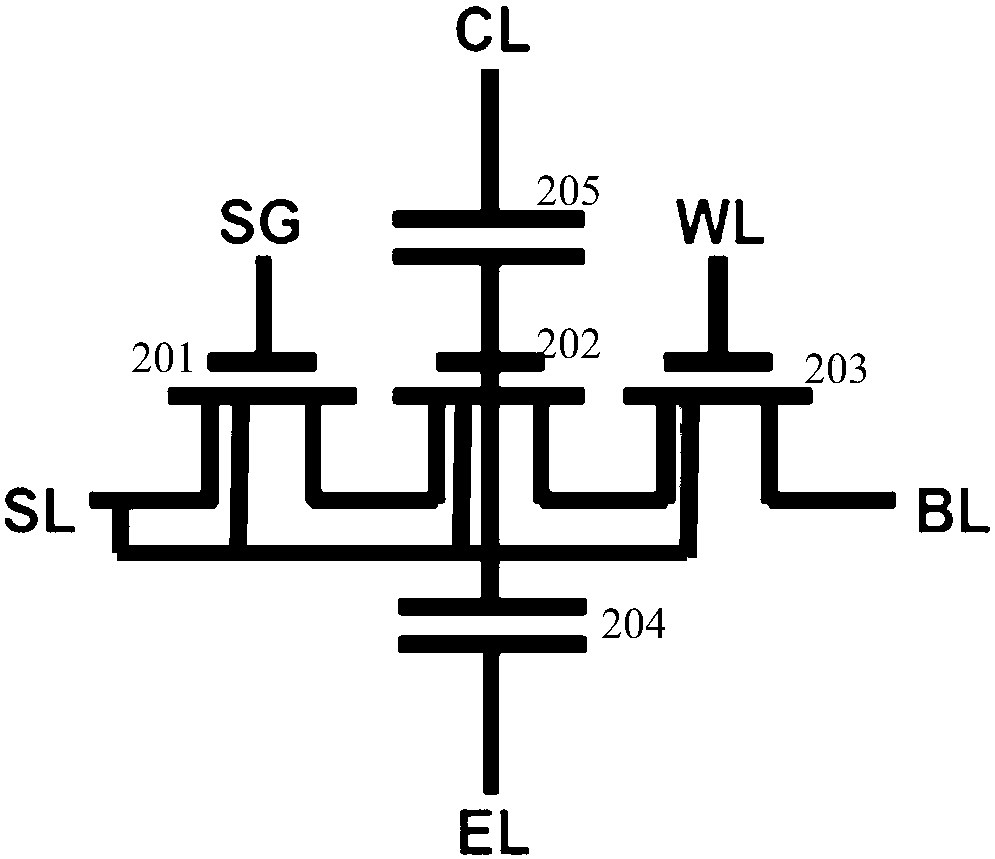

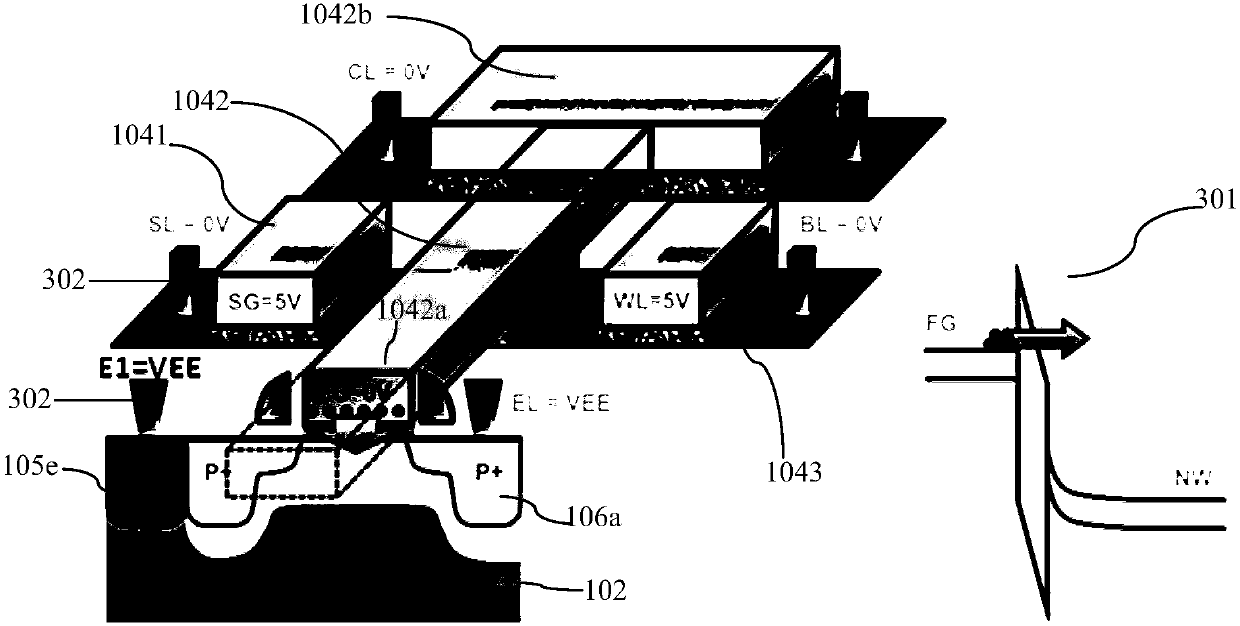

[0071] Before describing the embodiment of the present invention in detail, firstly analyze the reason why the MTP erasing failure occurs in the existing structure, and the technical solution of the present invention is creatively designed on the basis of analyzing these technical problems. like Figure 5A Shown is the layout corresponding to the P+ implantation region and the N+ implantation region in the erasing structure of the existing MTP device; Definition of the source area, Figure 5A The first active region 1021 is formed by the first well region 102 within the range of the first active region 1021 . A polysilicon gate including a polysilicon floating gate 1042 is formed thereafter. The extended end 1042a of the polysilicon floating gate 1042 crosses the first active region 1021 in the erased structure. Afterwards, implantation of the P+ region and the N+ region is required. Before the implantation, the implanted regions of the P+ region and the N+ region need to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com