Circular concrete pole production line and production process thereof

A concrete and production line technology, which is applied in the direction of manufacturing tools, reinforced molding, ceramic molding workshops, etc., can solve the problems of unreasonable production process layout, affecting the quality of poles, and low automation, so as to ensure high quality and stability, reduce Safety risks, the effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following will further describe in detail a ring-shaped concrete pole production line and its production process according to the present invention in conjunction with specific embodiments and accompanying drawings.

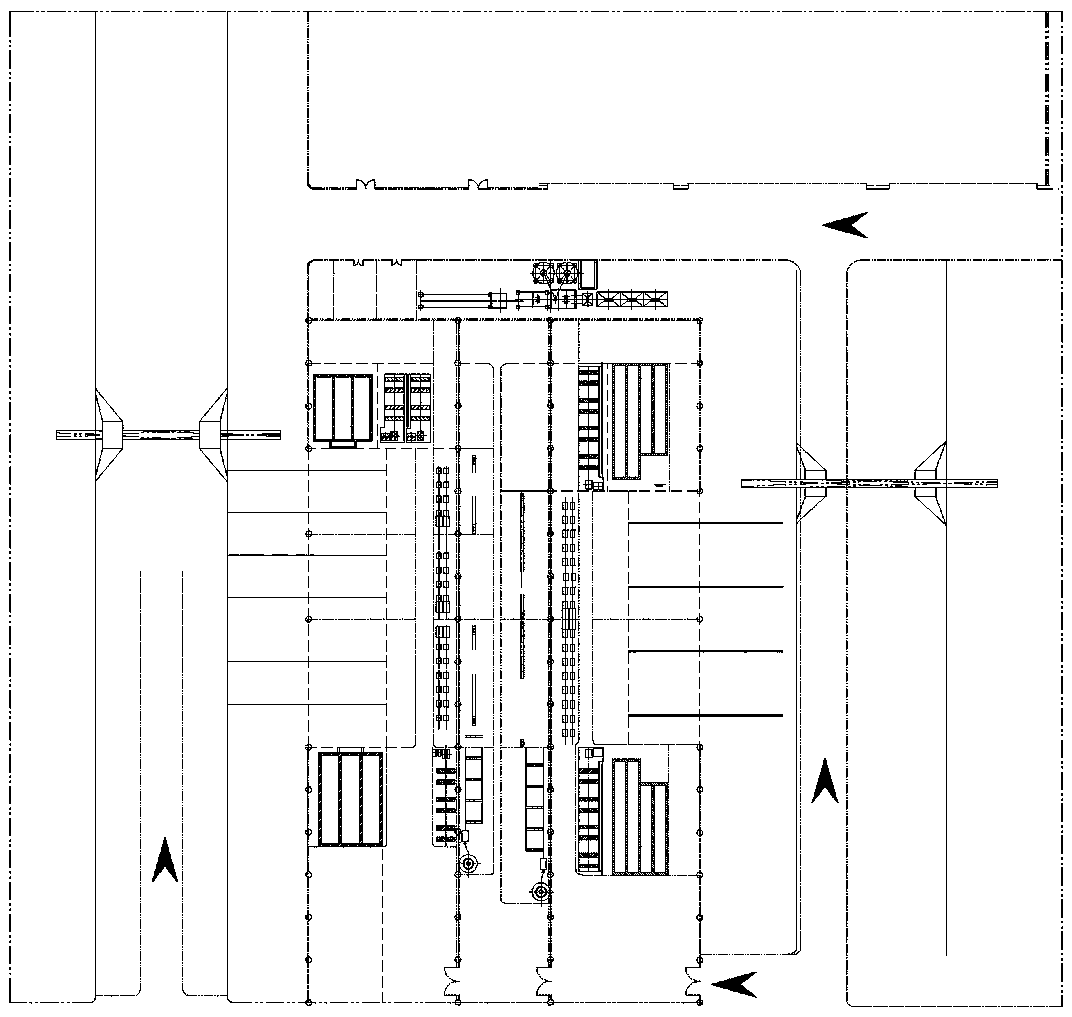

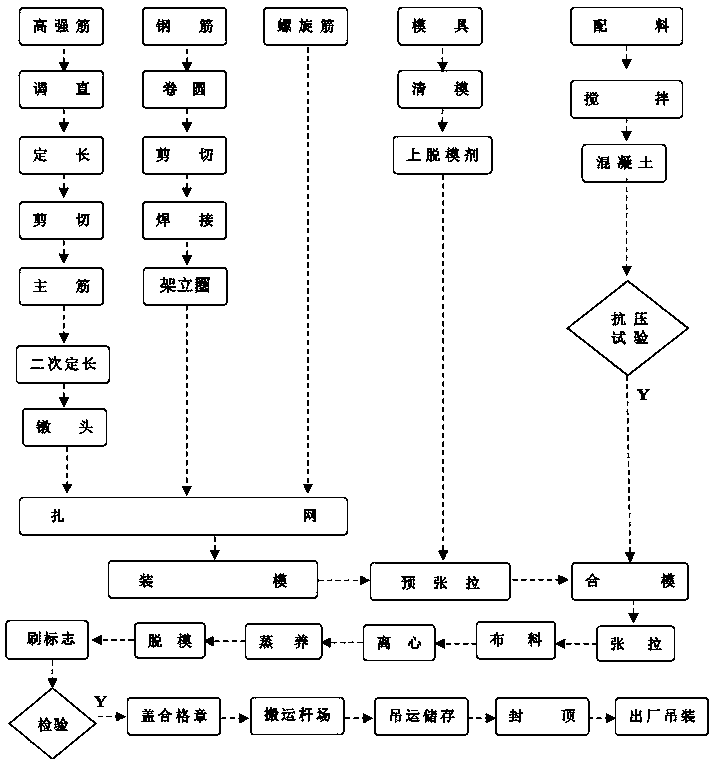

[0014] Such as figure 1 As shown, in a preferred embodiment, a ring-shaped concrete pole production line of the present invention includes a raw material warehouse, concrete mixing equipment, concrete pumping equipment, steel skeleton netting equipment, mold processing equipment, tensioning equipment, and centrifugal equipment , steam curing equipment and transportation equipment; the outlet of the raw material warehouse is connected to the inlet of the concrete mixing equipment, and the outlet of the concrete mixing equipment is connected to the inlet of the concrete pumping equipment; the transportation equipment is respectively divided into steel skeletons Between netting equipment and mold processing equipment, between mold processing equipment and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com