Single-track transportation system with buffer function

A transportation system and monorail technology, applied in the field of transportation systems, can solve problems such as bruising, affecting fruit storage and sales, and fruit collisions, and achieve the effects of avoiding violent collisions, improving stability, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

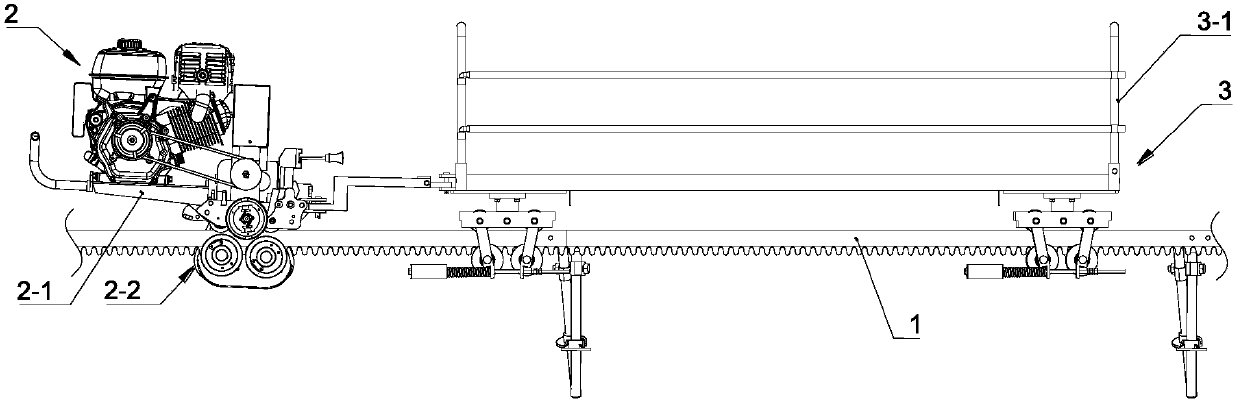

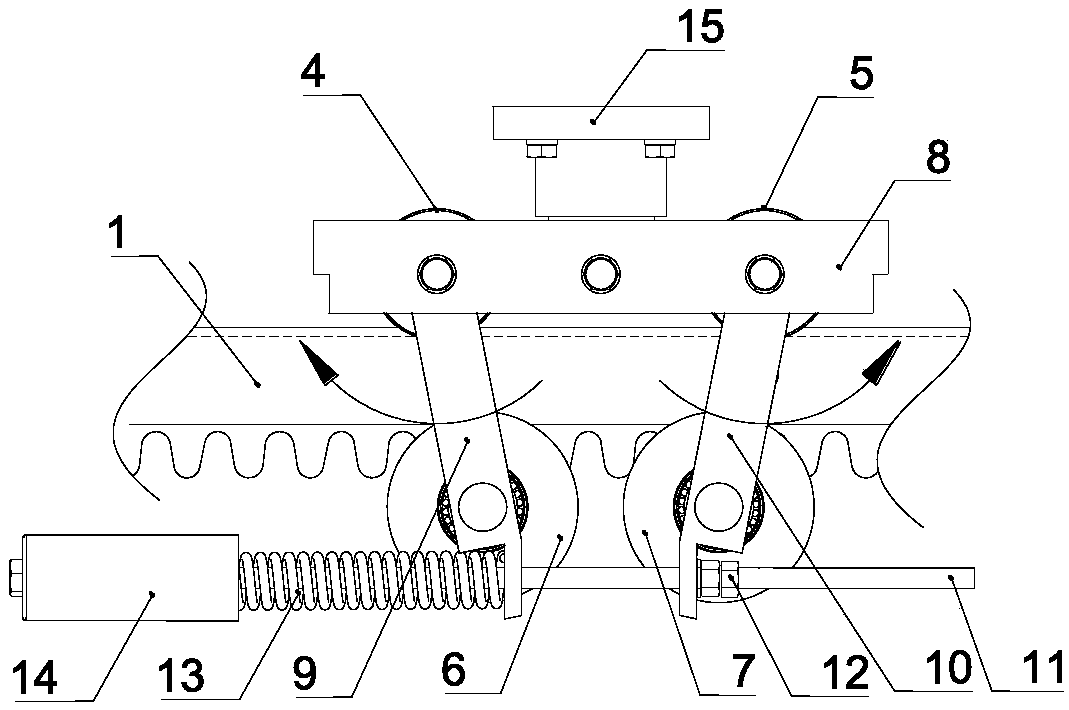

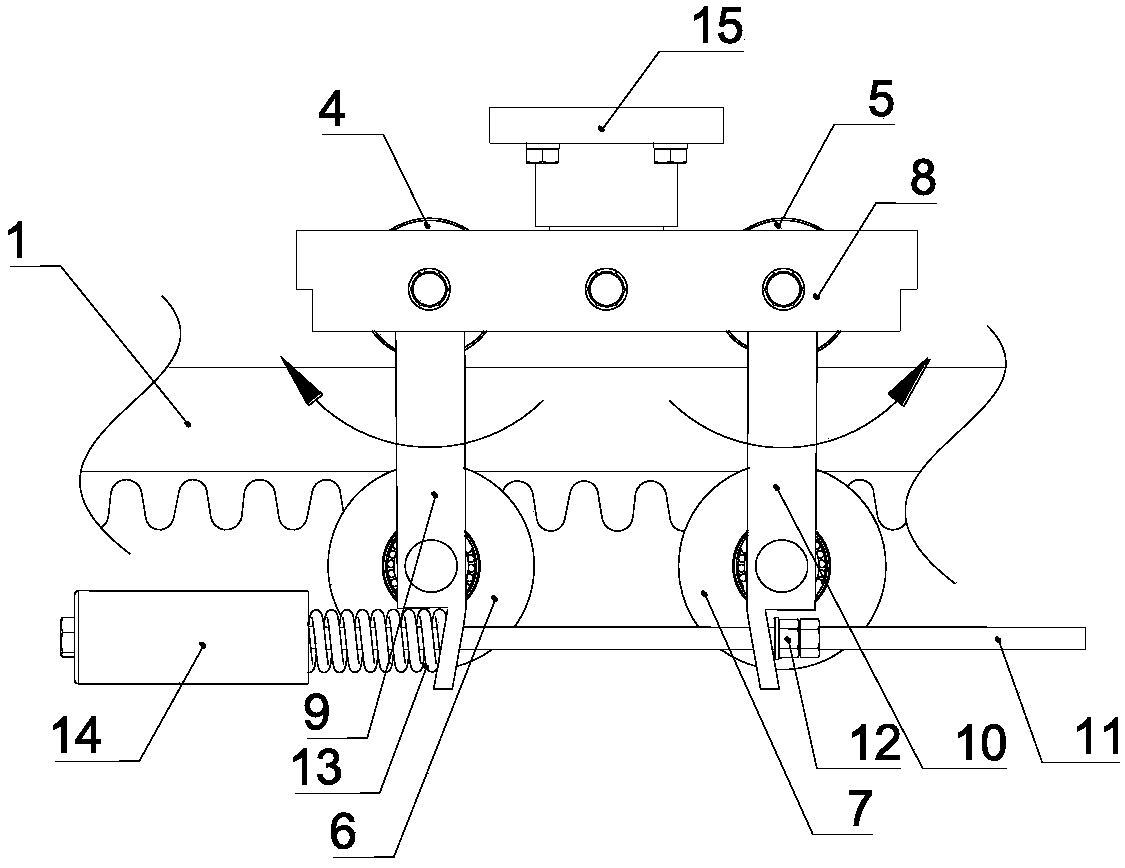

[0036] See figure 1 with figure 2 , A monorail transport system with buffer function of the present invention includes monorail 1 and a transport machine arranged on monorail 1, said monorail 1 is fixed on the hillside by a support frame, said transport machine includes a nose traction part 2 and a truck body Section 3; wherein the nose traction part 2 includes a frame 2-1, a drive wheel set 2-2 arranged below the frame 2-1, and an engine, a reduction gear box, and a brake arranged above the frame 2-1 Mechanism and shifting mechanism; the truck body 3 includes a body 3-1 and an anti-sway running mechanism arranged below the body 3-1, and the body 3 and the anti-sway running mechanism are connected by a support 15 , Wherein the vehicle body 3-1 is connected to the frame 2-1 through a connecting bar, and the anti-sway walking mechanism includes a first bearing wheel 4 and a second bearing wheel 5 arranged above the monorail 1, and The first anti-roller 6 and the second anti-roll...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 is that the vehicle speed in this embodiment is controlled by the vehicle speed limit module, which includes a speed sensor arranged on the nose of the machine, and the speed sensor is compatible with the speed sensor in the automatic control system. Control module connection. Through the above device, the speed sensor is used to detect the speed of the conveyor in real time. When the speed exceeds the set maximum value, the control module controls the hydraulic lever brake actuator to act and decelerate the conveyor by means of braking. The speed of the transporter is controlled within a certain range; the advantage of this setting is that the speed control module automatically controls the speed of the transporter instead of the handbrake or remote control manually. It has the advantages of good speed limit performance and high degree of automation. .

[0052] Refer to Example 1 for implementation of other implemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com