Engine oil balance system and operation method thereof

A technology of balancing system and oil, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of accelerated wear of motion pairs, increased viscosity of oil consumption, and difficulty in establishing oil film, so as to reduce fuel consumption, reduce wear, Technically significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

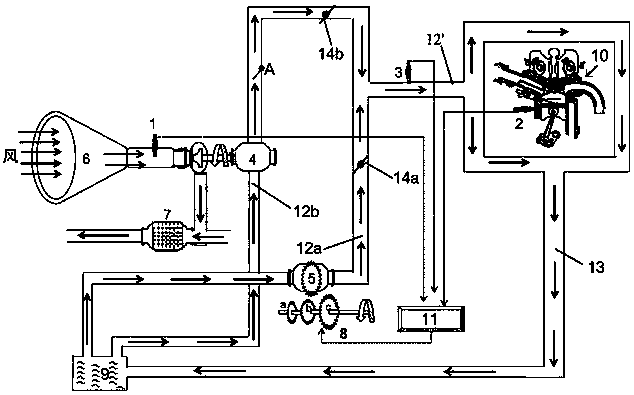

[0059] The structure and working principle of the engine oil balancing system of the present invention will be described below in conjunction with the accompanying drawings.

[0060] Such as figure 1 As shown, the engine oil balancing system disclosed in the present invention includes an oil pan 9 and an engine oil jacket 10 for storing engine oil. Oil flows from the oil pan 9 to the engine oil jacket 10 via the oil input line 12 a , the auxiliary oil input line 12 b and the oil input main line 12 ′, and from the engine oil jacket 10 back to the oil pan 9 via the oil return line 13 . from figure 1 As can be seen in the figure, the oil input pipeline 12a and the auxiliary oil input pipeline 12b are two parallel pipelines, they are connected to each other to form the main oil input pipeline 12 ′, and finally reach the engine oil jacket 10 .

[0061] A conventional oil pump 5 is fitted on the oil inlet line 12a. The conventional oil pump 5 communicates with the oil pan 9 via t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com