Method for coating a cylinder of an internal combustion engine, and cylinder for an internal combustion engine

A technology for an internal combustion engine and a cylinder, which is applied to the cylinder field of an internal combustion engine, and can solve the problems of unusable cylinders and unusable cylinders.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

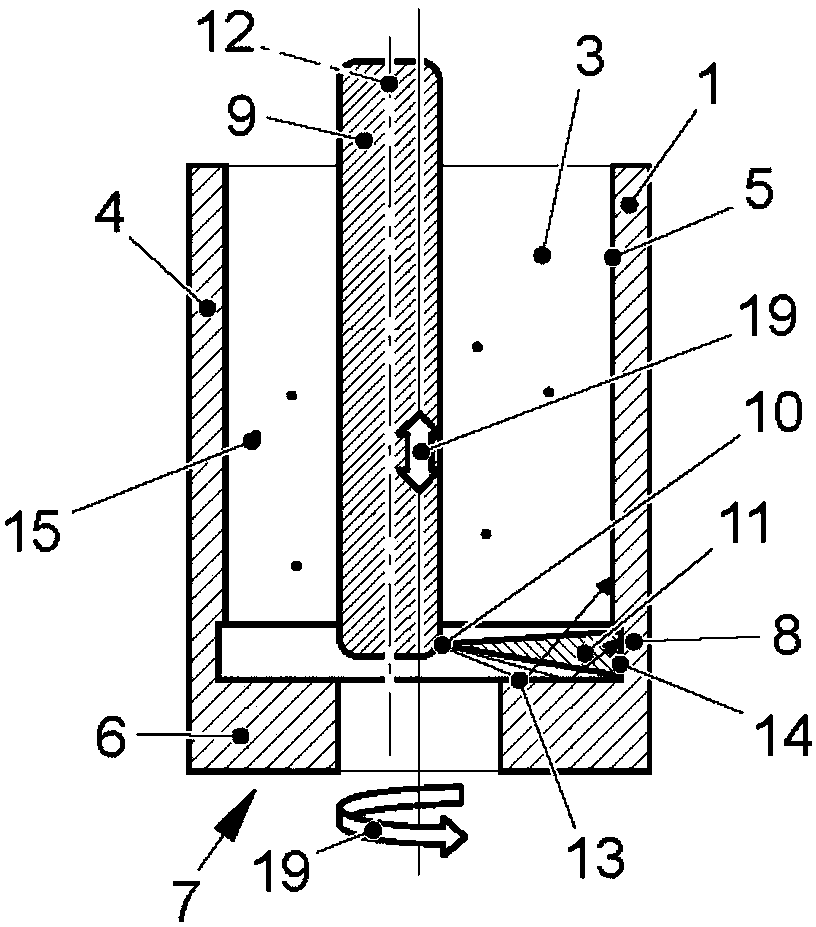

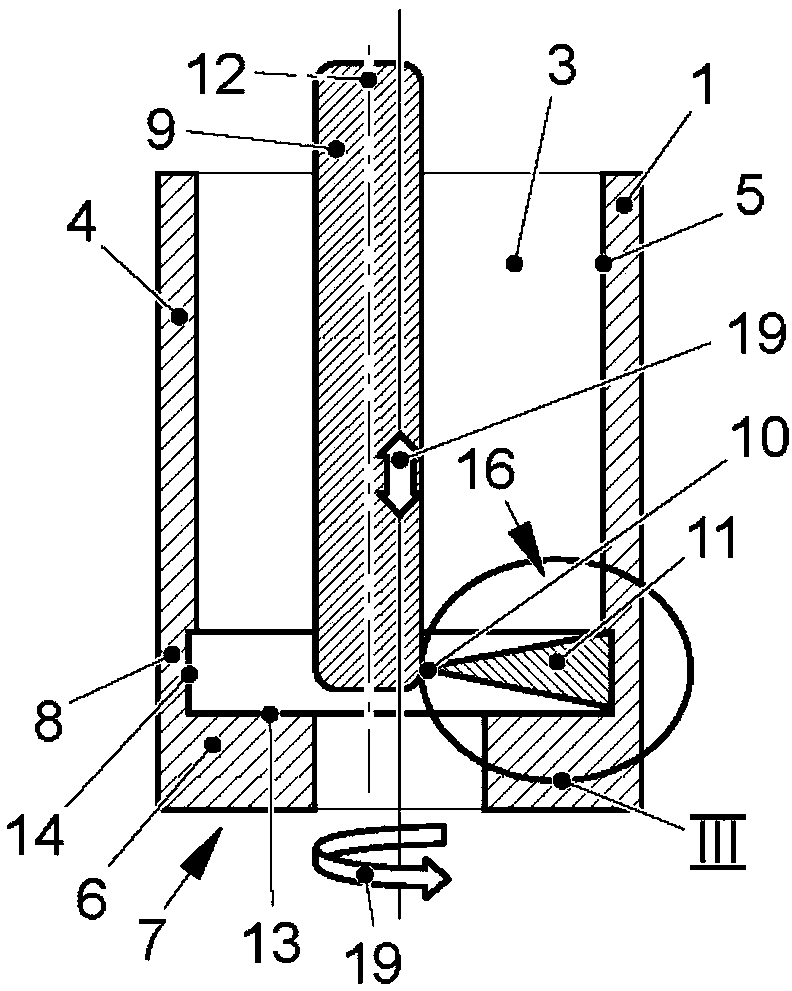

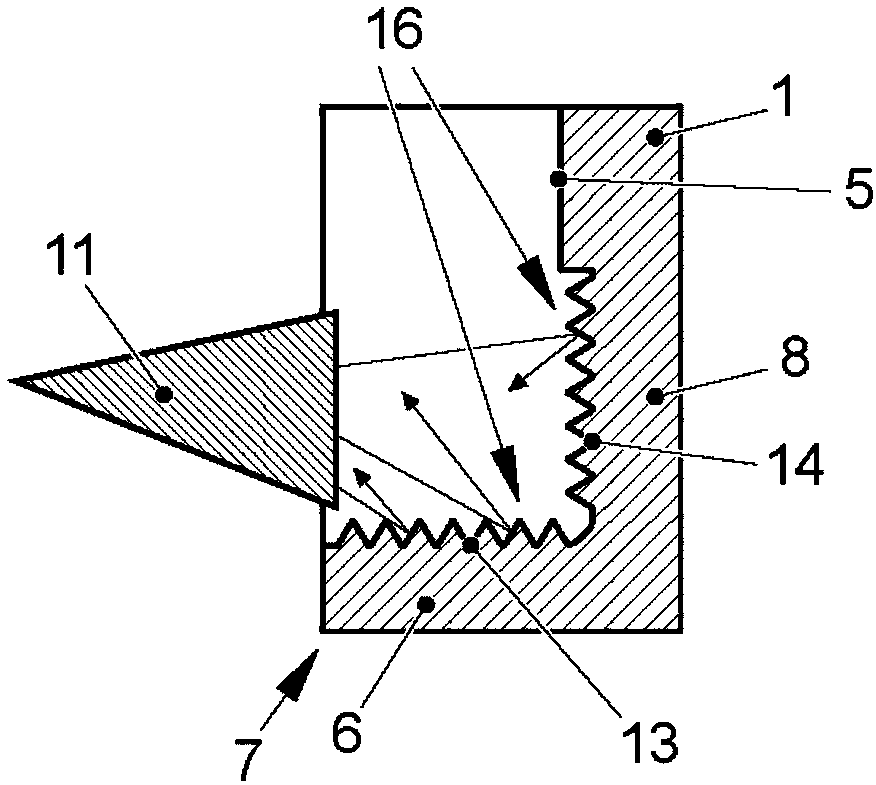

[0026] FIG. 1 shows a schematic illustration of a cylinder 1 of an internal combustion engine 2 during a method for coating according to the prior art.

[0027] Cylinder 1 is designed in the shape of a hollow cylinder and has an interior space 3 , in which a piston, not shown in detail, is accommodated during operation of internal combustion engine 2 to perform an oscillating movement. In the region of the running surface section 4 of the cylinder 1 , a coating of the cylinder 1 is provided on the piston running surface 5 , which is formed facing the interior 3 , in order to reduce wear between the cylinder 1 and the piston. The running surface section 4 is the section of the cylinder 1 which is in contact with the piston or its piston rings during operation.

[0028] The cylinder 1 is embodied in the crankcase 7 and comprises: a bearing section surface 13 of the bearing section 6 of the crankcase 7 , which is provided for supporting a crankshaft (not shown in detail) of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com