Carburized layer thickness detecting device and method

A detection method and detection device technology, applied in the direction of measuring device, electromagnetic measuring device, electric/magnetic thickness measurement, etc., can solve problems such as inadaptability to rapid inspection, trouble, etc., and achieve the effects of efficient nondestructive testing, portability, and small error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

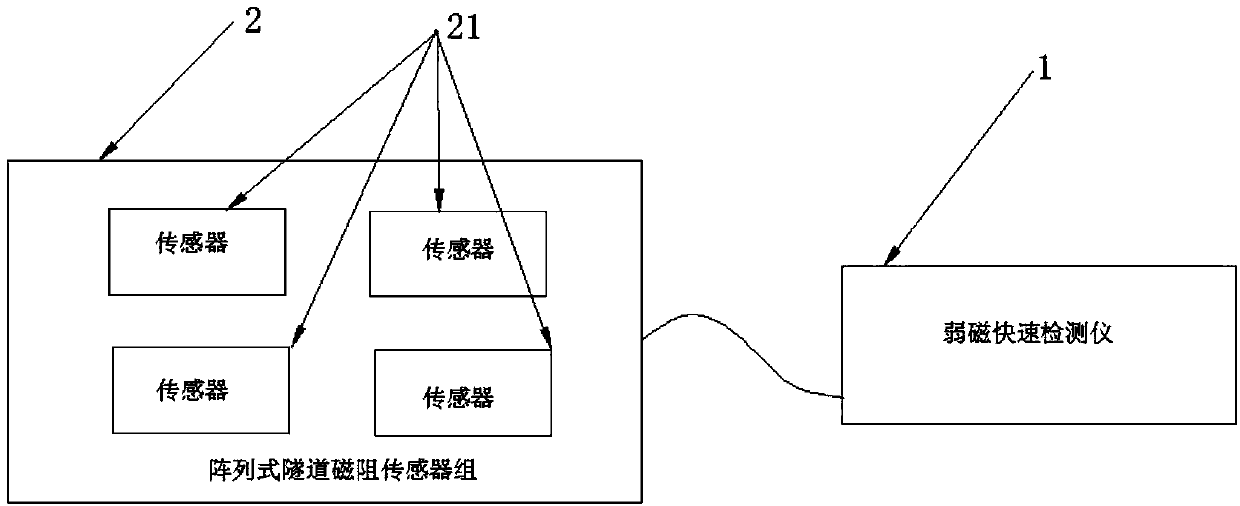

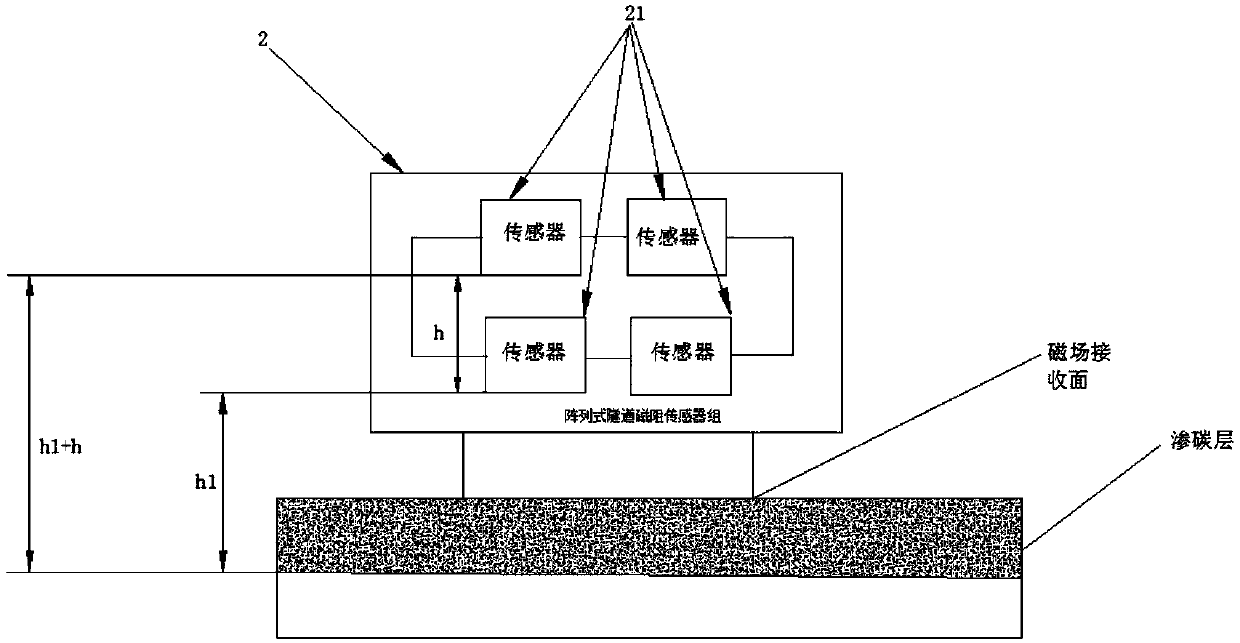

[0025] Such as figure 1 As shown, a detection device for the thickness of a carburized layer includes a connected magnetic field weakening fast detector 1 and an arrayed tunnel magnetoresistive sensor group 2 . Among them, the magnetic field weakening fast detector 1 converts the magnetic induction signal in the welding seam into an electrical signal for analysis and processing, and the array type tunnel magnetoresistive sensor group 2 is used to collect the magnetic induction signal.

[0026] In a further step, the above-mentioned arrayed tunnel magneto-resistive sensor group 2 includes four sensors 21, and these four sensors 21 are all connected to the above-mentioned weak magnetic fast detector 1, and the four sensors 21 are divided into two rows on average, the first row above the second row.

[0027] During detection, the bottoms of the group of tunnel magnetoresistive sensors 21 are attached parallel to the surface of the workpiece to be detected, that is, the detection...

Embodiment 2

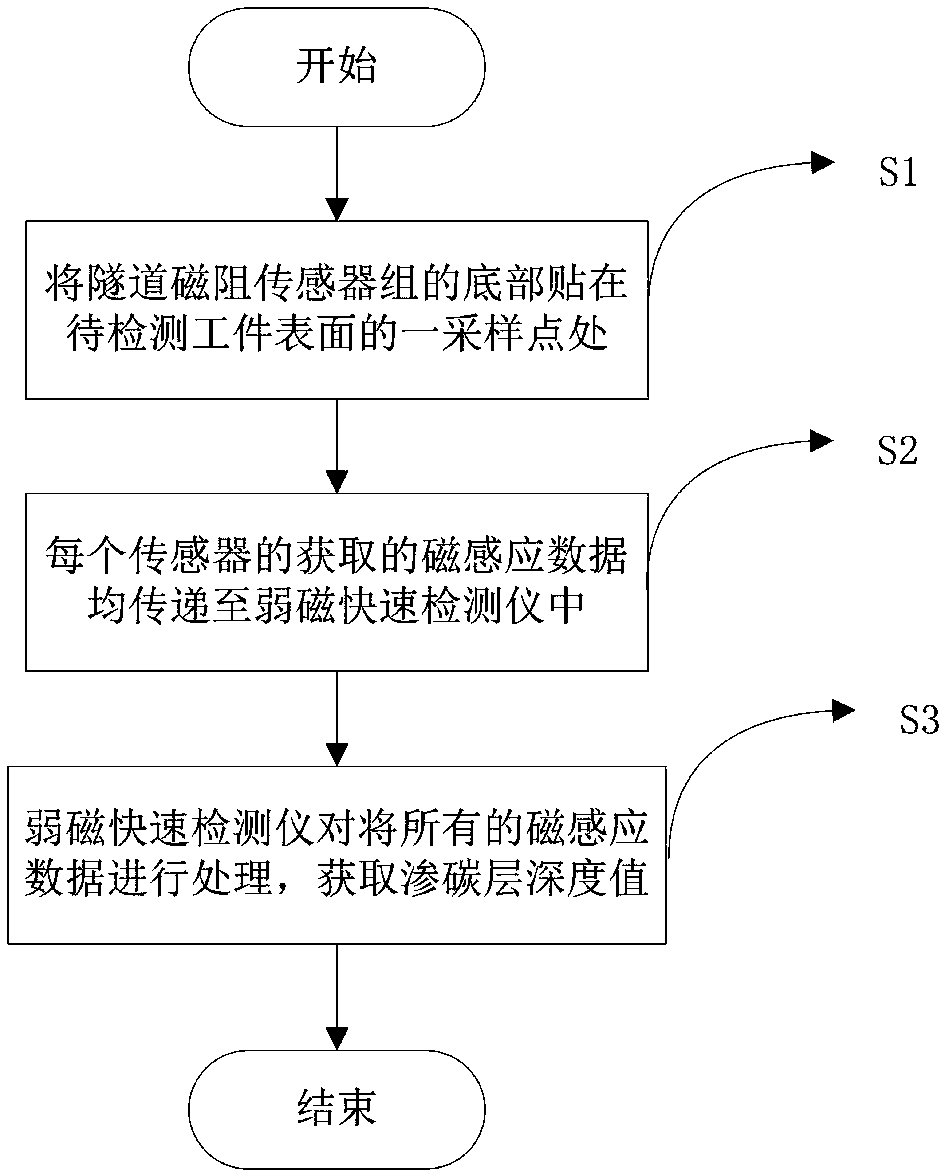

[0030] Such as figure 2 and 3 Shown, a kind of detection method of carburized layer thickness comprises steps:

[0031] S1. Paste the bottom of the group of tunnel magnetoresistive sensors 21 on a sampling point on the surface of the workpiece to be detected;

[0032] S2. The magnetic induction data obtained by each sensor 21 is transmitted to the magnetic field weakening fast detector 1;

[0033] S3. The magnetic field weakening fast detector 1 processes all the magnetic induction data to obtain the carburized layer depth value.

[0034] In the above method, it is necessary to attach the bottom of the tunnel magnetoresistive sensor 21 group to the surface of the workpiece to be detected during detection, and then transmit the magnetic induction data acquired by each sensor 21 to the magnetic field-weakening fast detector 1 in real time. The detector 1 reprocesses all the magnetic induction data to obtain the depth value of the carburized layer.

[0035] It is worth point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com