Phased array ultrasonic probe with adjustable wafer array angle and assembling and detecting method thereof

A phased array and ultrasonic technology, which is applied in the field of ultrasonic testing, can solve the problems of fixed probe wafer array and inability to adjust detection requirements, and achieves the effect of good uniformity and small dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

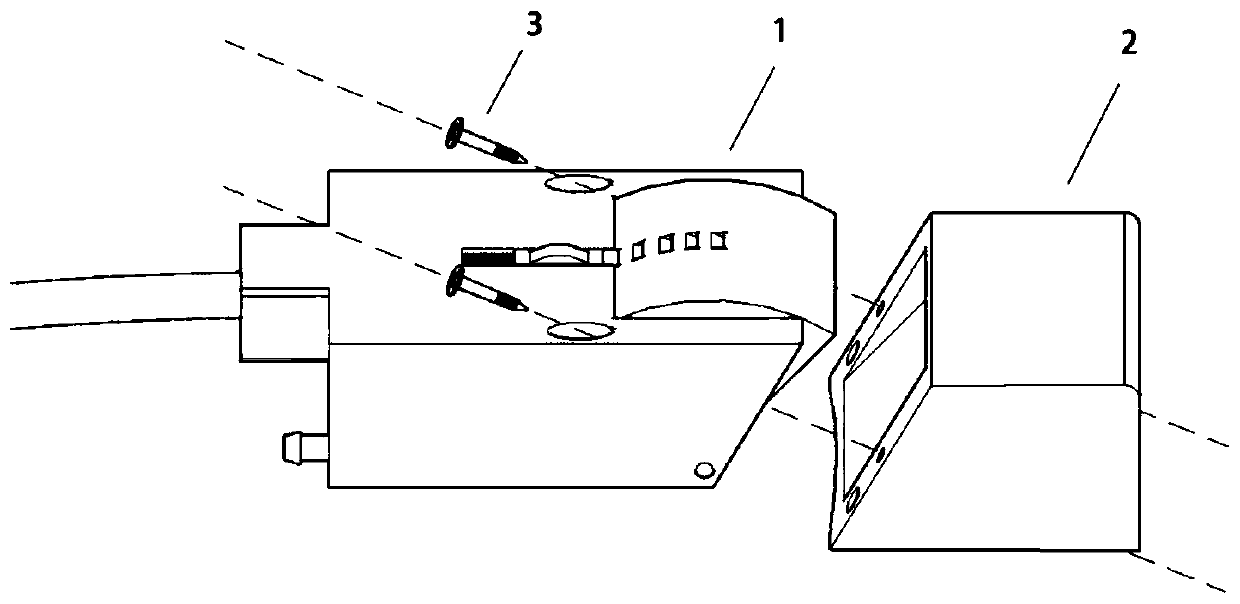

[0031] figure 1 Shown is a schematic diagram of structural decomposition of the present invention.

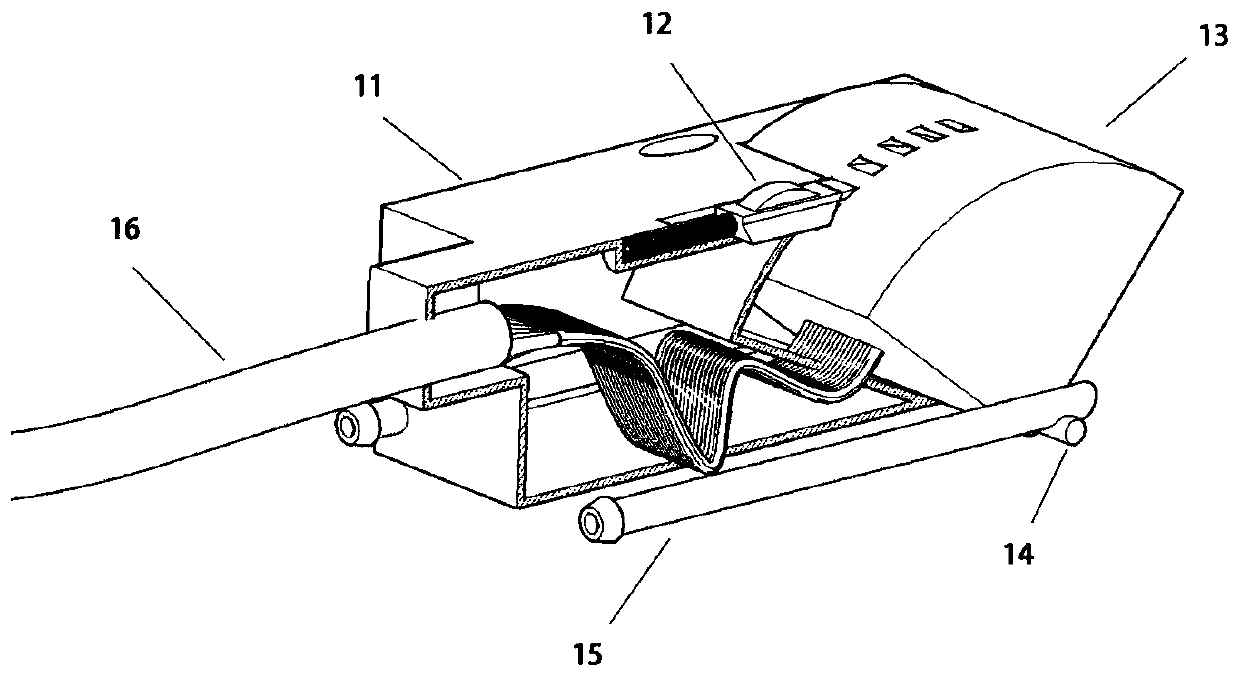

[0032] figure 2 Shown is a schematic structural view of the probe base of the present invention.

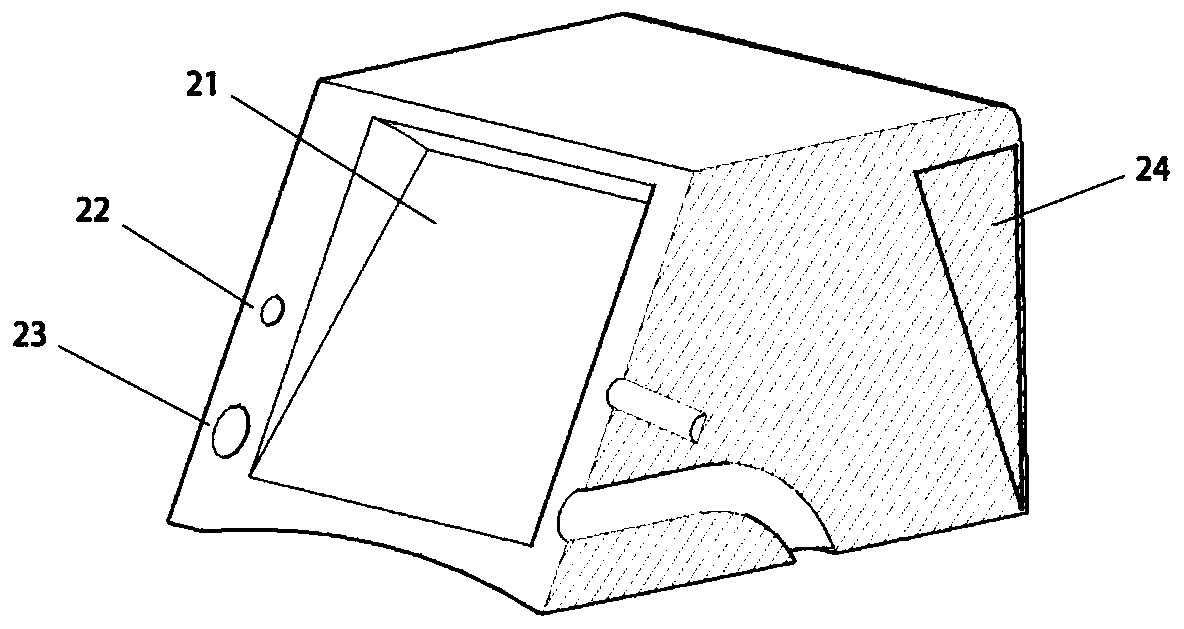

[0033] Image 6 Shown is the appearance schematic diagram of the present invention.

[0034]The present invention provides a phased array ultrasonic probe with an adjustable wafer array angle, which includes a probe base 1 and a wedge 2. The probe base 1 includes a probe housing 11, a locking device 12, a wafer array module 13, a connecting shaft 14, Couplant conduit 15 and probe cable 16; the probe housing 11 is a trapezoid as a whole, and its front end is a fan-shaped body cavity for installing the wafer array module 13, and the wafer array module 13 is fixed on the probe housing 11 through the connecting shaft 14 The front end can rotate smoot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com