Device for leveling motor vehicles

A level adjustment, motor vehicle technology, applied in the direction of transmission, vehicle springs, vehicle parts, etc., can solve the problems of expensive necessary components and cumbersome assembly, and achieve the effect of low assembly cost and component cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

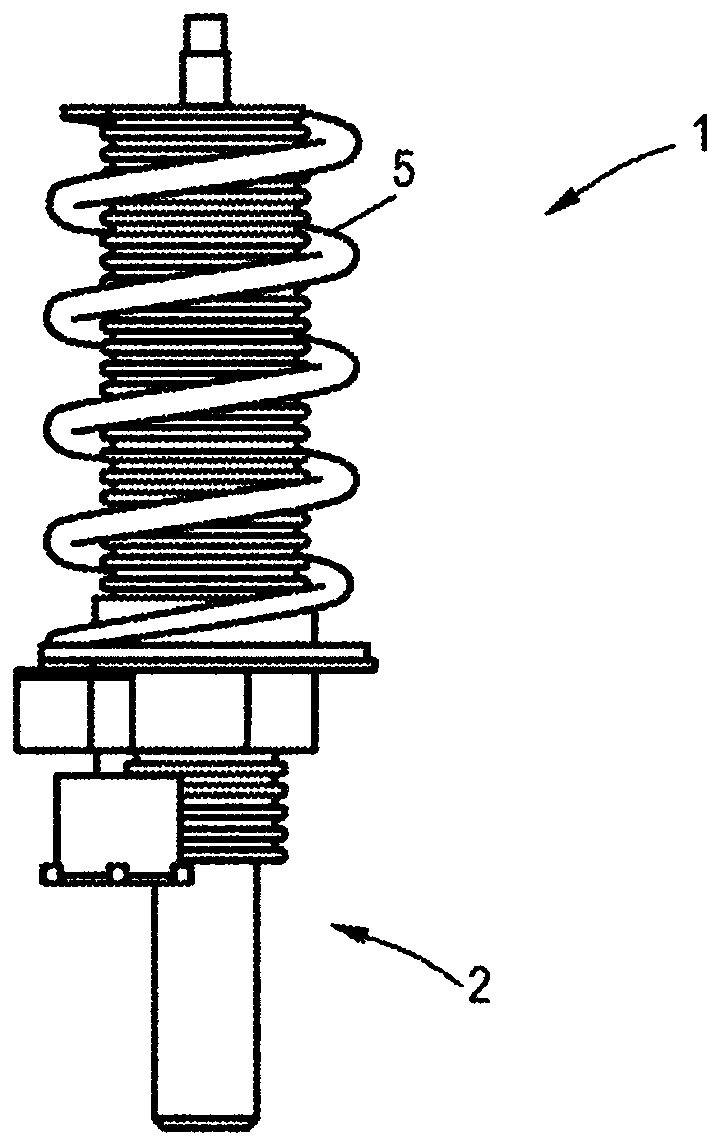

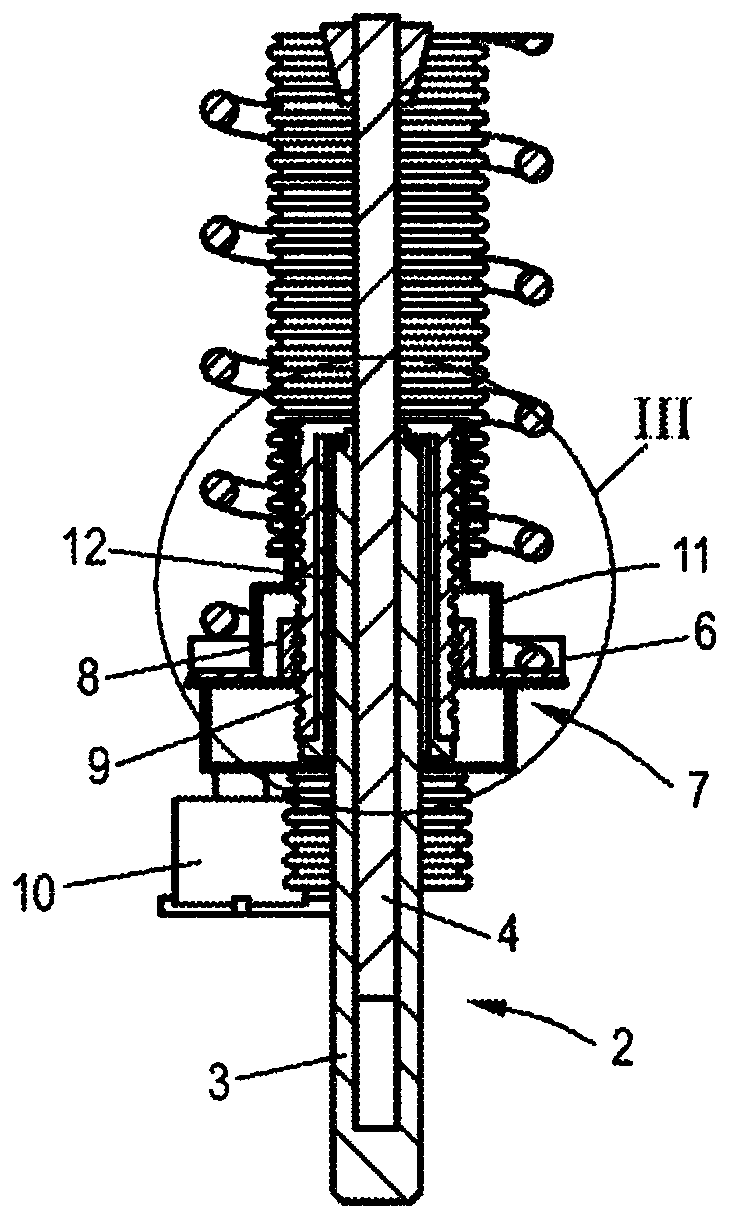

[0028] figure 1 A device 1 for leveling a motor vehicle is shown, comprising a piston-cylinder unit 2 with a cylinder 3 and a piston 4 movable in the cylinder 3, the piston 4 being connected to the chassis via a vibration-damping bearing in a manner not shown in detail , while the cylinder 3 is connected on the wheel carrier side in a manner not shown in detail.

[0029] In addition, a spring 5 is provided which is elastically compressed and springs back in a known manner during operation, wherein this movement is damped by the piston-cylinder unit 2 which acts as a damping device. The bottom position of the spring 5 is supported on a disc element 6 which can be moved axially on its side by means of a ball screw drive, so that the spring bottom position for level adjustment can be raised or lowered. In addition to ball screw drives, different screw drives can also be used.

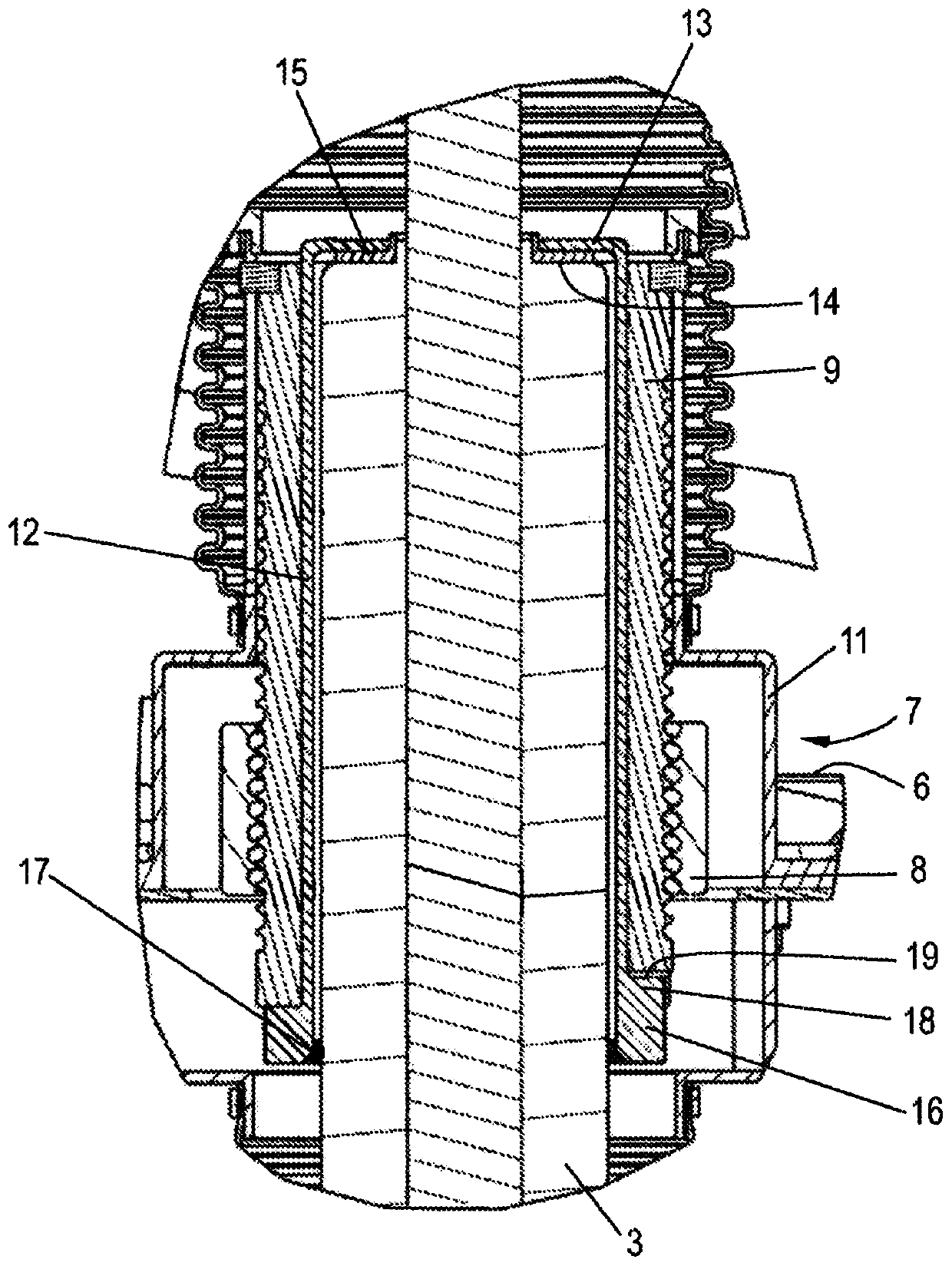

[0030] The ball screw drive 7 comprises a nut 8 which extends and moves axially on a threaded rod 9 g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com