Airport baggage conveying device

A technology for handling device and luggage, which is applied to conveyor control device, transportation and packaging, conveyors, etc., can solve the problems of unsuitable handling of checked luggage in large-flow airports, inability to ensure the stability of luggage, and complex structure of the transportation system. The effect of avoiding personal safety problems, improving space utilization, and promoting development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

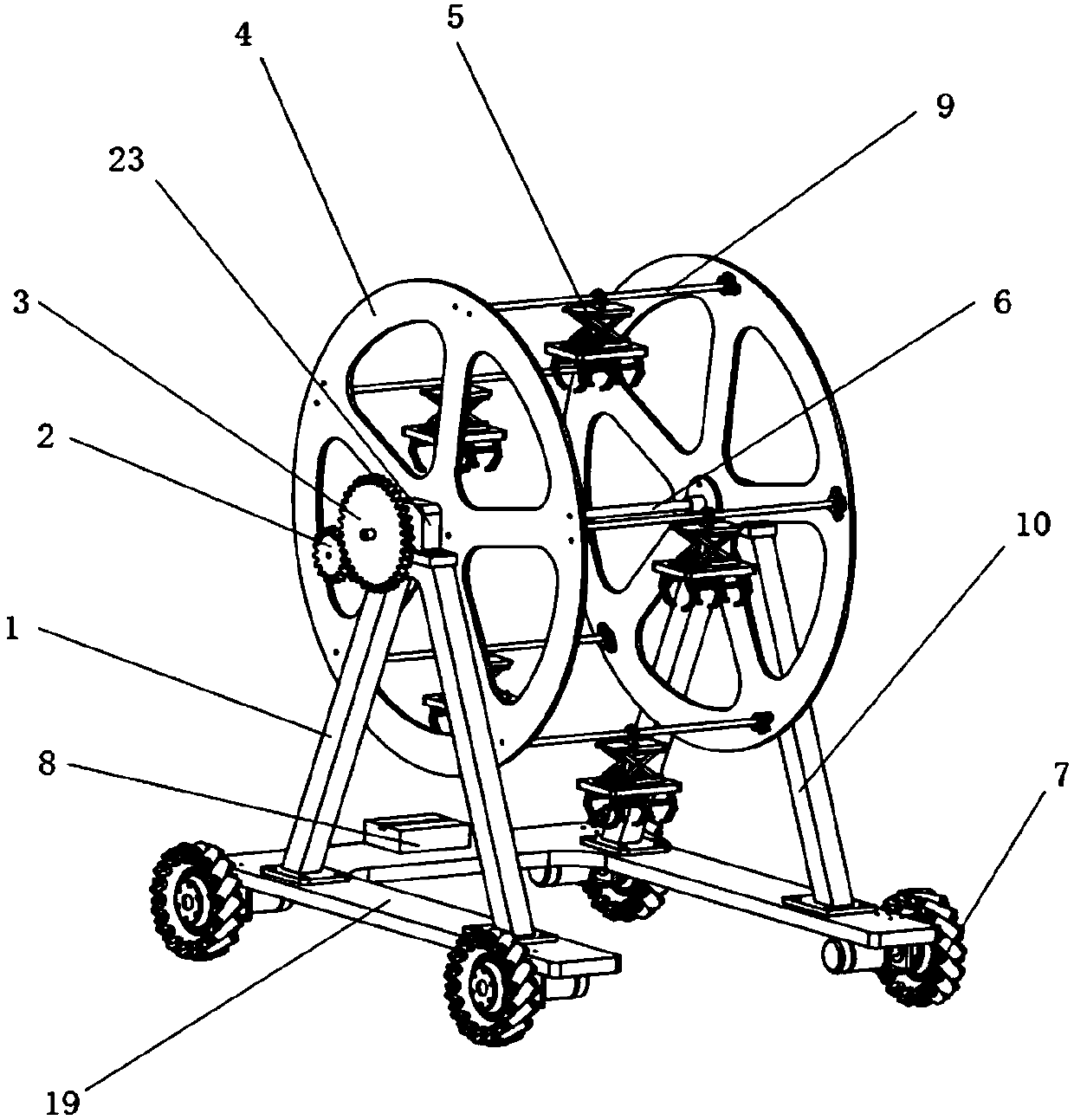

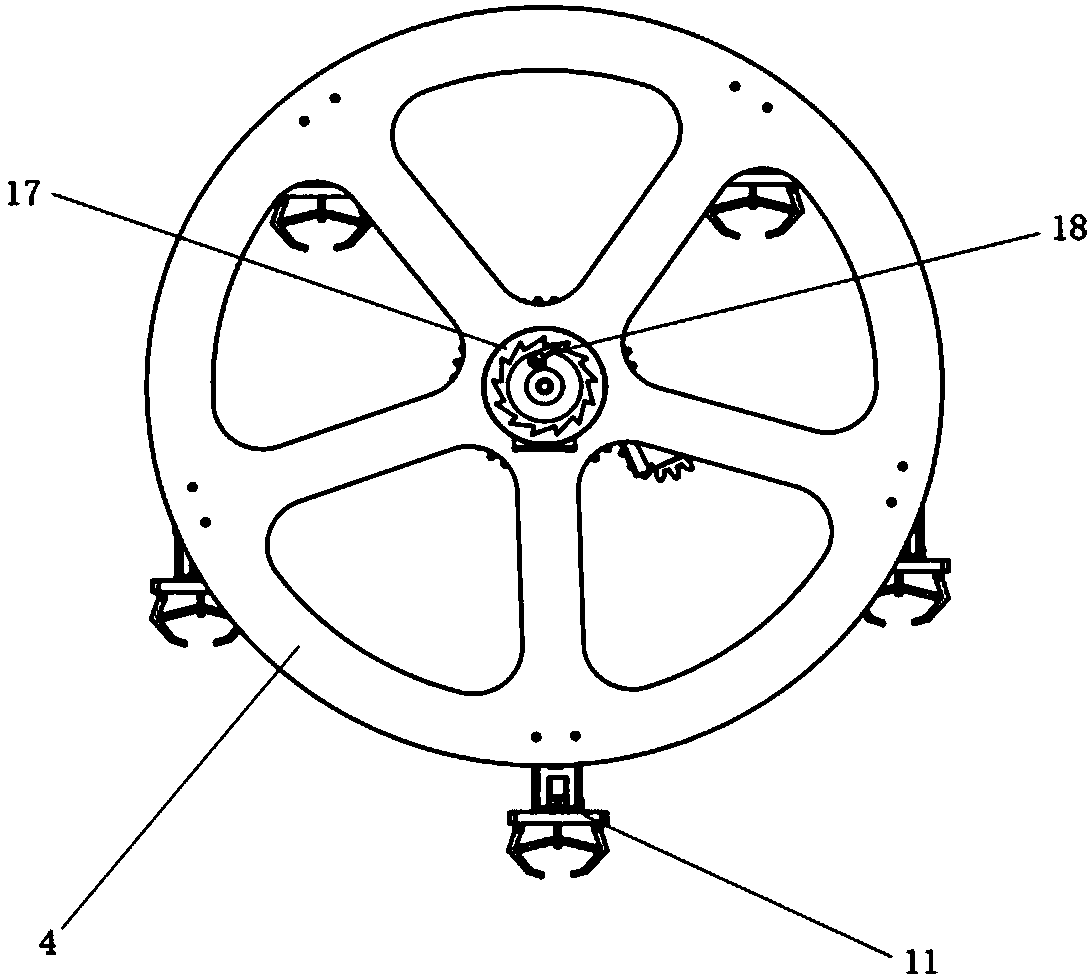

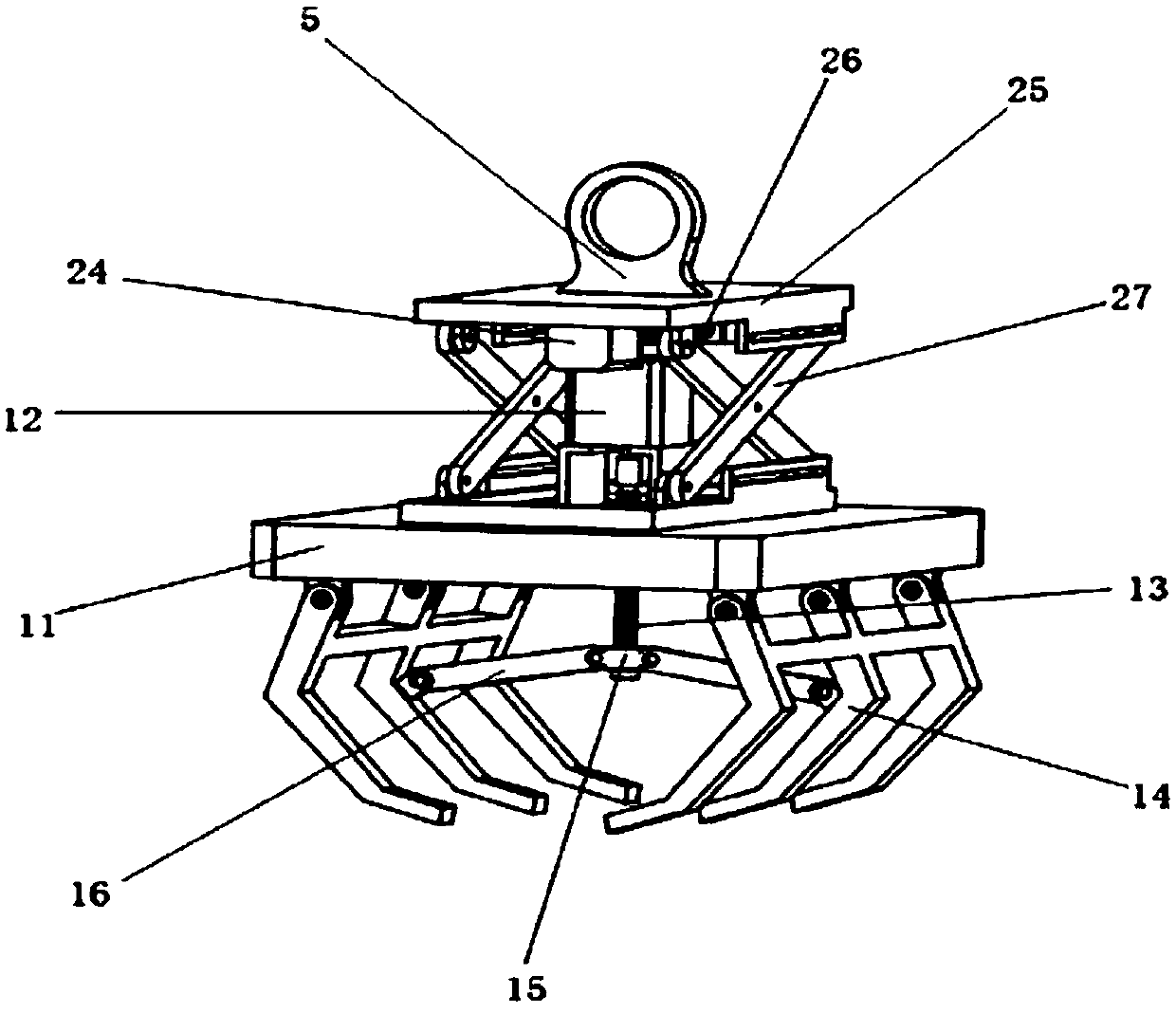

[0032] An airport luggage handling device, comprising a disc-type lifting mechanism, grippers 5 and a running mechanism, the bottom plate 19 is a “gate-shaped” member with an open front, and the wheel motor 20 is fixed to the lower part of the bottom plate 19 through a motor fixing part 21, The output shaft of the wheel motor 20 is fixed with the drive wheel 7 through the flange coupling 22, and the legs of the two herringbone supports 1 are respectively fixed with the upper surfaces of the left and right sides of the base plate 19, and the disc type lifting mechanism consists of two symmetrical circular Disc 4 and its connecting piece polished rod 9 are formed. The center of disc 4 is provided with a central shaft 6, and the two ends of the central shaft 6 are fixed to the tops of the herringbone brackets on the left and right sides t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com