Ferrous product oil immersion mechanism with oil drum capable of achieving lifting

A technology for iron products and oil drums, which is applied in the field of oil immersion mechanisms for iron products, which can solve problems such as low efficiency, large manual labor, and omissions, and achieve the effect of high efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

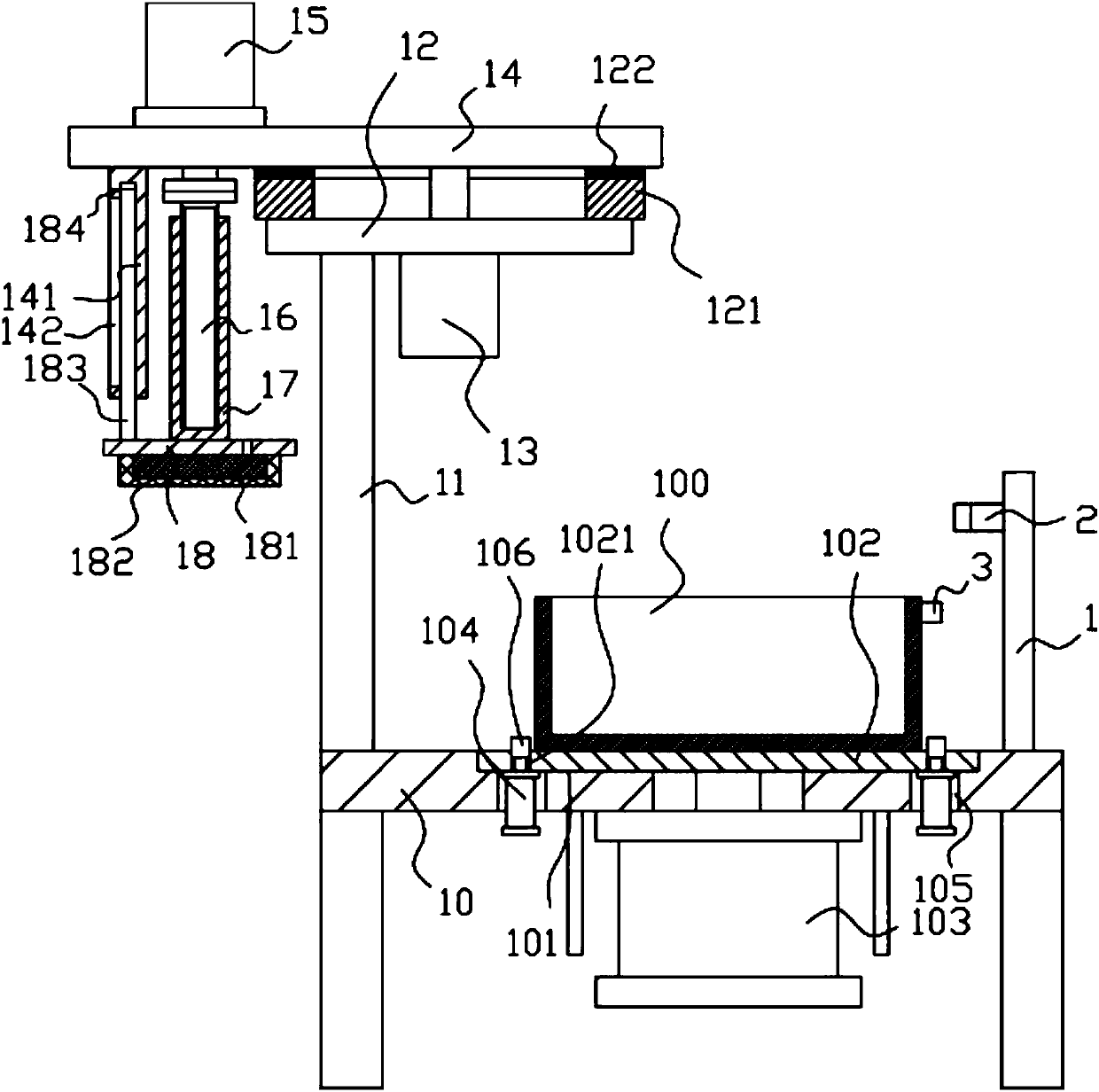

[0016] Example: see figure 1 Shown, a kind of iron product oil immersion mechanism that oil barrel can lift, comprises frame 10, and the middle top surface of the top plate of described frame 10 has placement groove 101, and placement plate 102 is placed in placement groove 101, places The bottom surface of the plate 102 is pressed against the bottom surface of the placement groove 101, and the bottom surface of the middle part of the top plate of the frame 10 is fixed with a lifting cylinder 103, and the push rod of the lifting cylinder 103 passes through the central through hole that the middle part of the bottom surface of the placement groove 101 has. Fixed on the bottom surface of the placement plate 102, the oil drum 100 is pressed against the top surface of the placement plate 102;

[0017] The top edge of the top plate of the frame 10 is fixed with a vertical support column 11, the top surface of the vertical support column 11 is fixed with a support plate 12, the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com