Recovery connector for drilling

A joint and drill pipe technology, applied in the field of recovery joints for drilling, can solve the problems of construction environment damage, lack of collection and treatment, etc., and achieve the effect of avoiding proliferation, broad application prospects, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

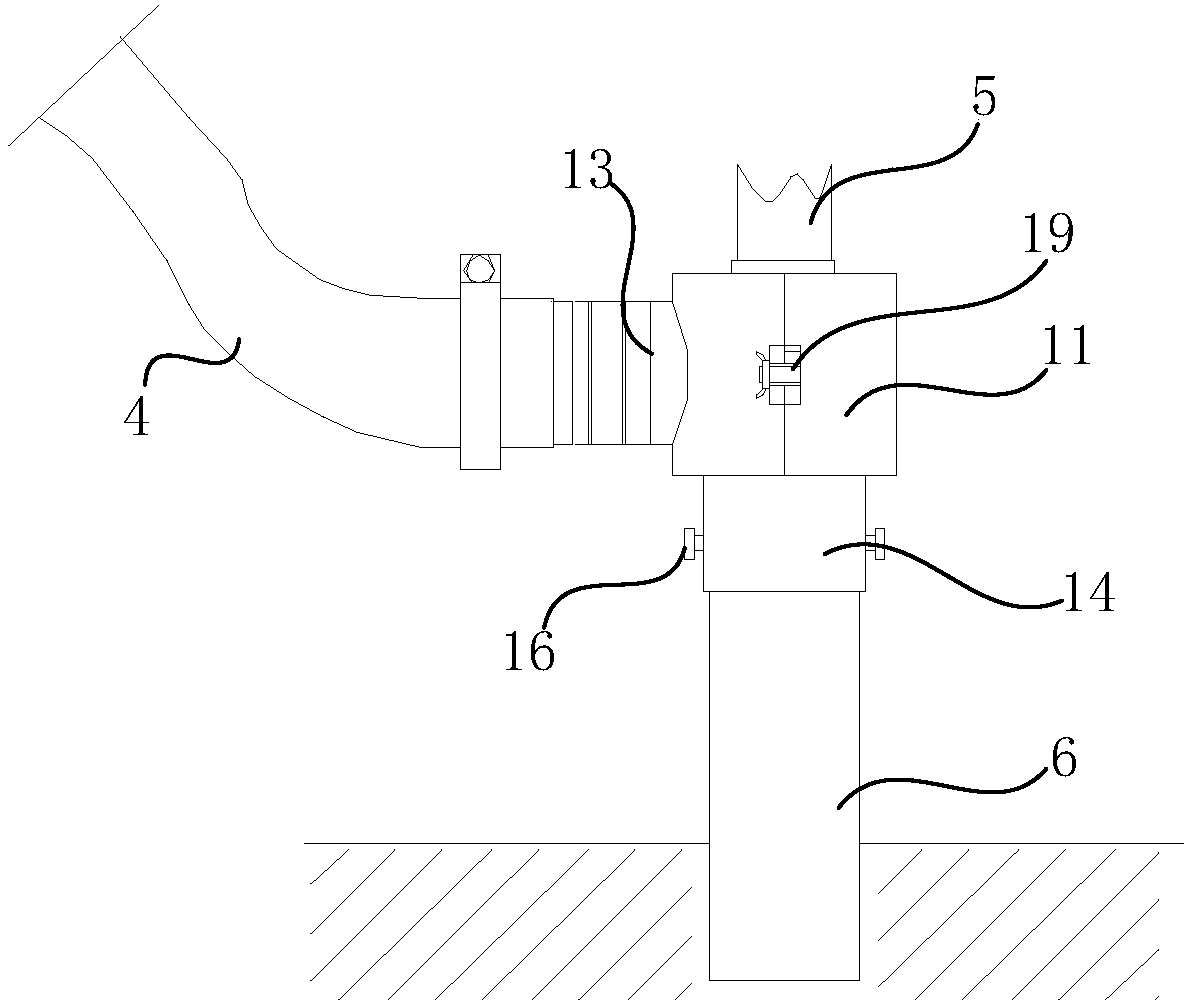

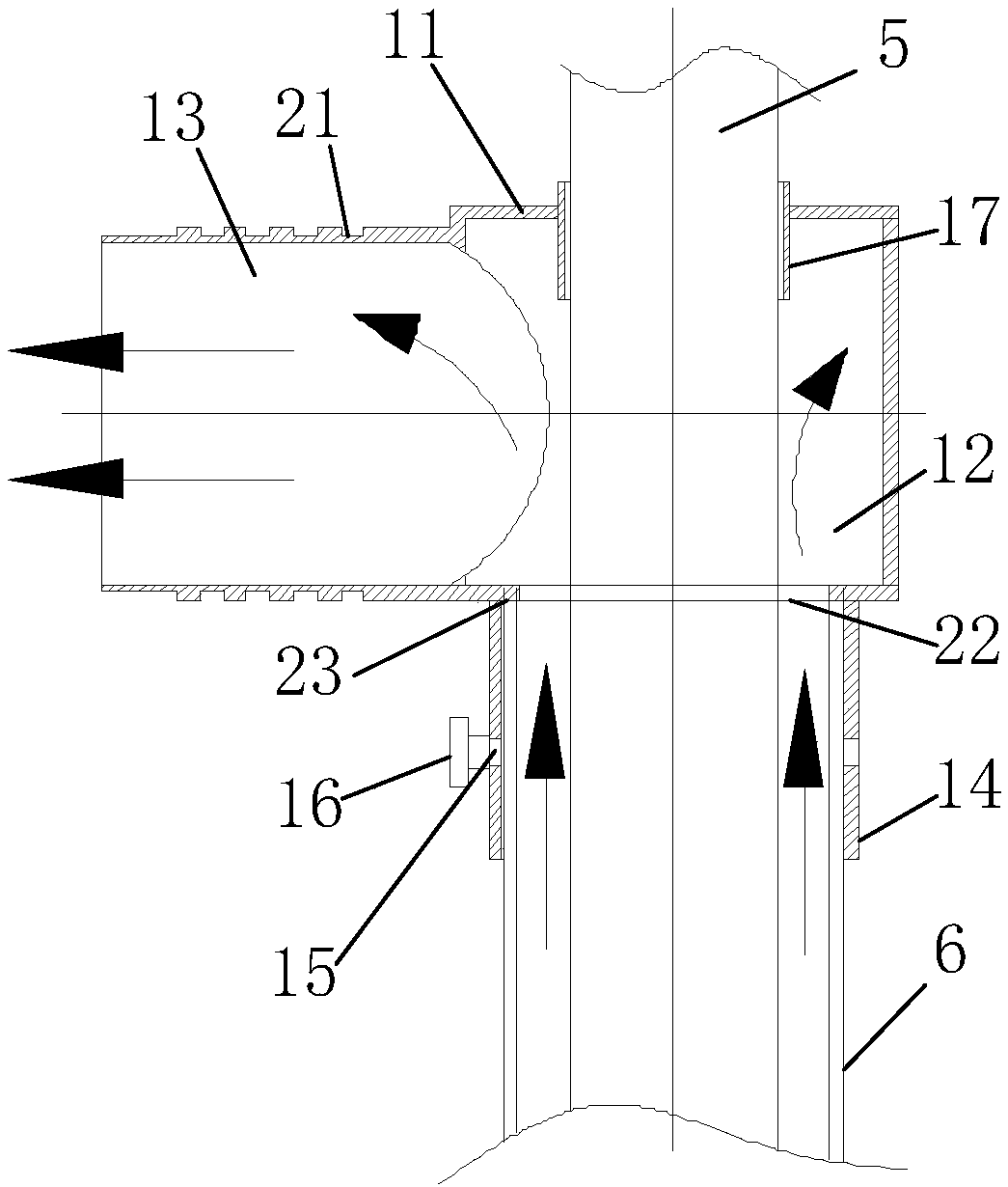

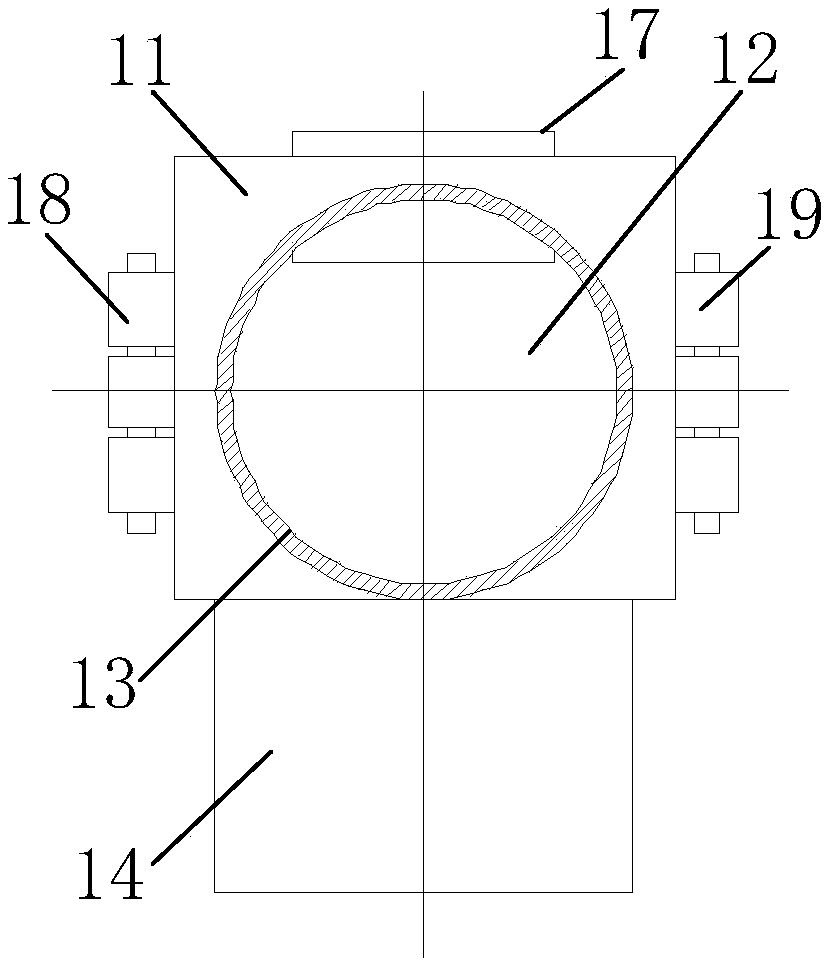

[0022] Such as Figure 1 to Figure 3 As shown, the recovery interface for drilling is mainly used to recover various solid-liquid gas substances produced during percussion drilling in exploration and coring engineering. It is sleeved on the drill pipe 5 and connected to the upper end of the casing 6 of the drill pipe. Specifically, it includes two fastening shells 11 that are fastened to each other and form a docking chamber 12, a joint pipe 13 that is connected to one fastening shell and communicates with the docking chamber for connecting the pipeline 4, and is arranged on the fastening The installation pipe 14 at the lower part of the shell and communicated with the docking chamber, wherein the inner diameter of the installation pipe matches the outer diameter of the casing, and at least two bolt holes 15 are provided on the pipe wall of the installation pipe, and each bolt hole has a A fastening bolt 16 for connecting the casing is provided, and a drill pipe passage hole m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com