Power-driven power generation method for device assembled to running electric vehicle

A power-driven, electric vehicle technology, applied in the direction of electric vehicles, electric components, mechanisms that generate mechanical power, etc., can solve the problem of power consumption of the vehicle body, and achieve the effect of weight reduction and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be described in detail below through the accompanying drawings and specific embodiments.

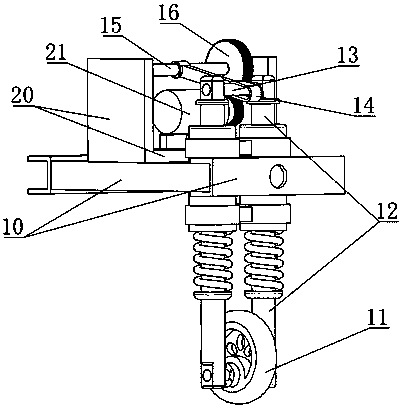

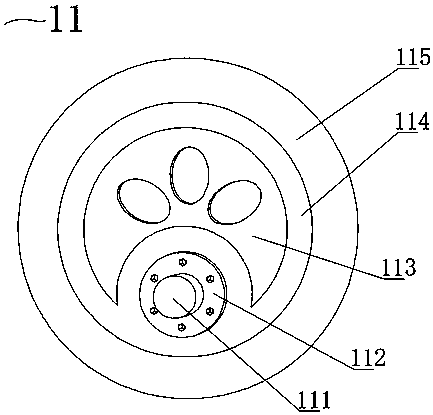

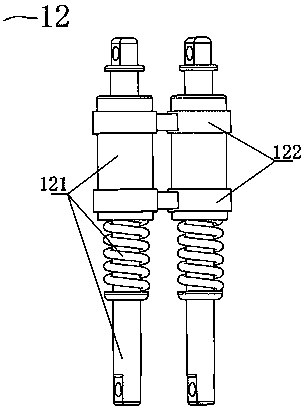

[0032] Such as Figure 1 to Figure 11 As shown, a power-driven power generation method assembled on an electric vehicle when driving, including a transmission device 1 and a power generation device 2, is characterized in that: the transmission device 1 includes an electric vehicle chassis 10, a cam wheel 11, a shaft 111, and a hub 112, wheel disc 113 retaining ring 114, tire 115, driver device 12, driver 121, drive shaft 1211, hole 12111, spring support ring 12112, hole 12113, spring 1212, sleeve 1213, spring limit ring 12131, shaft limit Ring 12132, fixed bracket 122, ferrule 1221, ferrule 1222, connecting rod 1223, shaft 13, push rod 14, straight notch shaft port 141, spline shaft port 142, spline shaft 15, spline 151, spline 152, gear 16, said devices are installed and fixed on the electric vehicle chassis 10, the two ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com