Supercharging device for oil well metering station and supercharging method

A technology of pressurization device and metering station, which is applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of wasting effective resources, long oil pipelines, pipeline blockage, etc., and achieves convenient and fast construction and installation. High degree of digitalization and the effect of reducing oil well back pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in further detail below in conjunction with accompanying drawing:

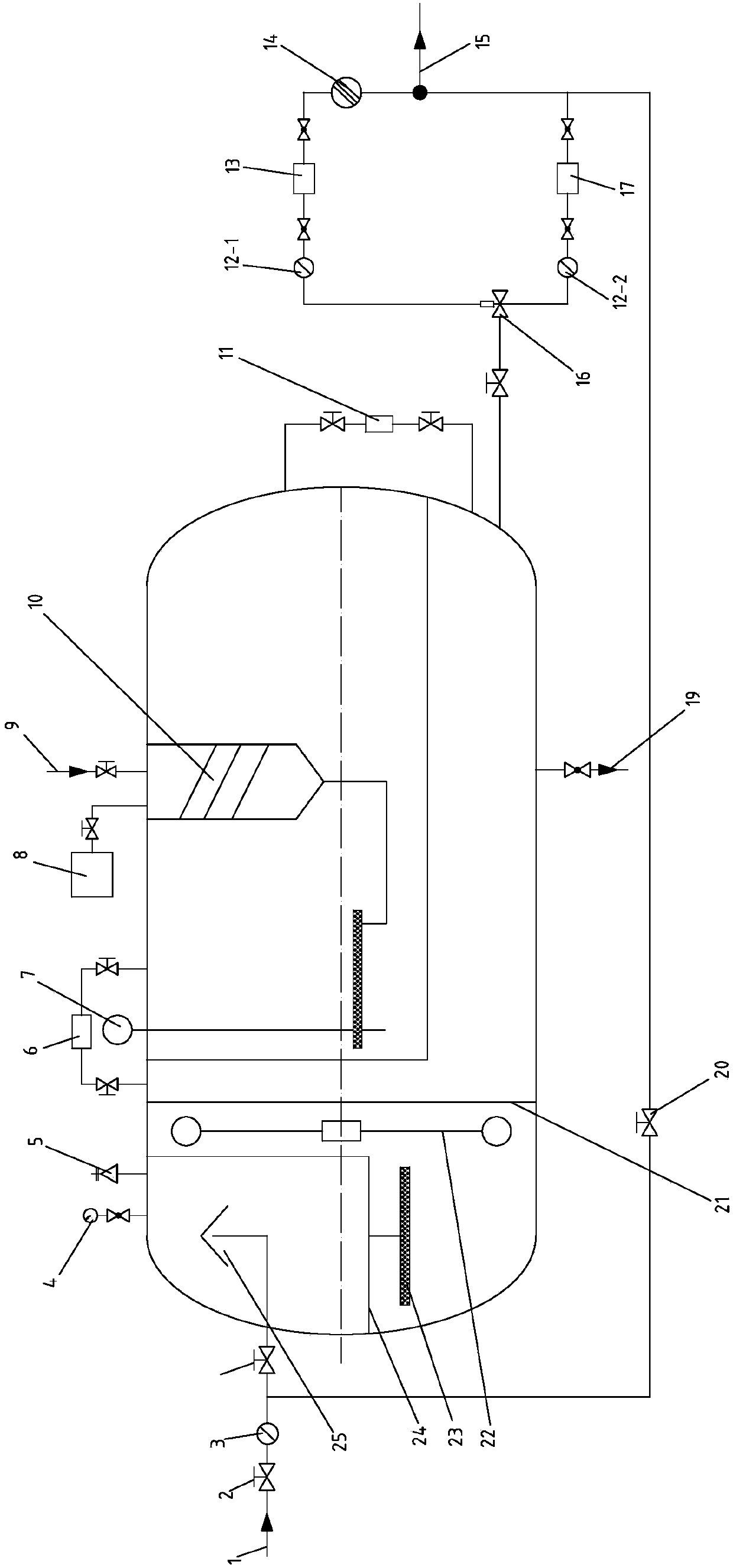

[0040] see figure 1: The present invention is used for the pressurization device of the oil well metering station, including a separator, and one end of the separator is connected to a multi-well liquid inlet pipeline 1, and oil, gas and water for the multi-well liquid inlet pipeline 1 are arranged in the separator Separation equipment; the other end of the separator is connected to a single well liquid inlet pipeline 9, and an oil-gas-water separation device for the liquid inlet of the single well liquid inlet pipeline 9 is arranged inside the separator; the lower end of the separator The oil-water outlet is connected to the inlet of the electric reversing valve 16 through a pipeline; the electric reversing valve 16 is provided with two outlets, and one outlet of the electric reversing valve 16 is connected to the first filter 12-1 through a pipeline. The inlet of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com