Universal probe assembly

A general-purpose, component-based technology, applied in the direction of measuring instrument components, measuring devices, instruments, etc., can solve problems such as inability to ensure repeatable measurement accuracy, failure to meet the measurement force requirements of the measured workpiece, and springs that cannot meet the measurement force requirements. The effect of avoiding sensor scrapping, high accuracy of repeated measurement, and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

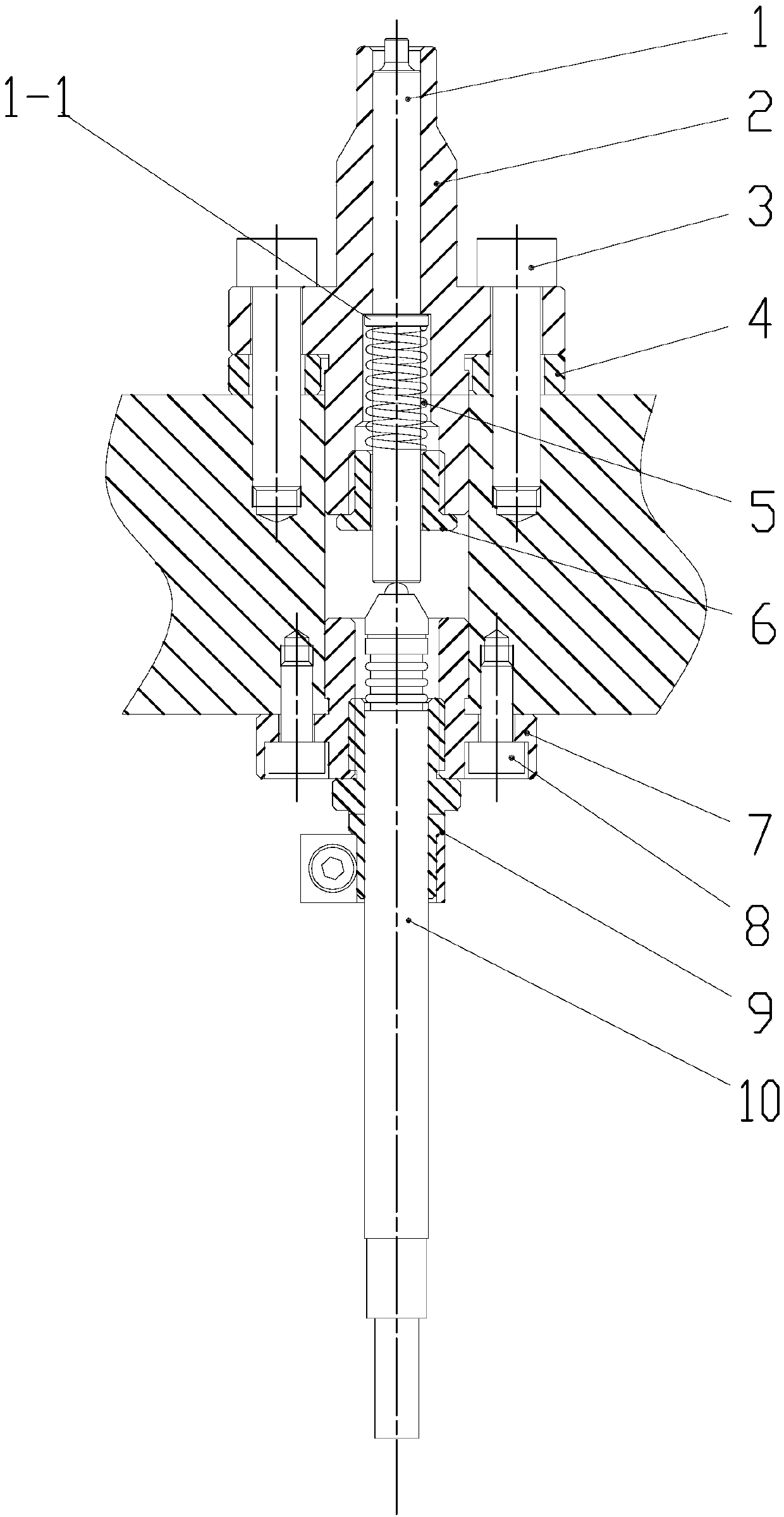

[0011] figure 1 , including measuring rod 1, radial protrusion 1-1, measuring rod guide sleeve 2, first screw 3, adjusting washer 4, spring 5, reducing nut 6, connecting seat 7, second screw 8, sensor Locking components 9, sensors 10, etc.

[0012] Such as figure 1 As shown, the present invention is a general-purpose measuring head assembly, which includes a mounting base, a measuring rod guide sleeve 2 is arranged on the upper part of the inner hole of the mounting base, and a measuring rod 1 is slidably fitted in the inner hole of the measuring rod guide sleeve 2. A spring 5 is sleeved on the rod 1, and the upper end of the spring 5 is pressed against the radial protrusion 1-1 on the surface of the measuring rod 1, and the upper surface of the radial protrusion 1-1 passes through the step of the inner hole of the measuring rod guide slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com