Cultivation method for returning whole straw to paddy field and special harrowing and burying roller device

A pressing roller device and paddy field technology, which is applied in the fields of harrowing, application, agriculture, etc., can solve the problems affecting the balance of soil organic matter components, unsatisfactory burial effect, and increased production costs, so as to avoid the straw crushing link and facilitate transplanting operations , Improve the effect of soil composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

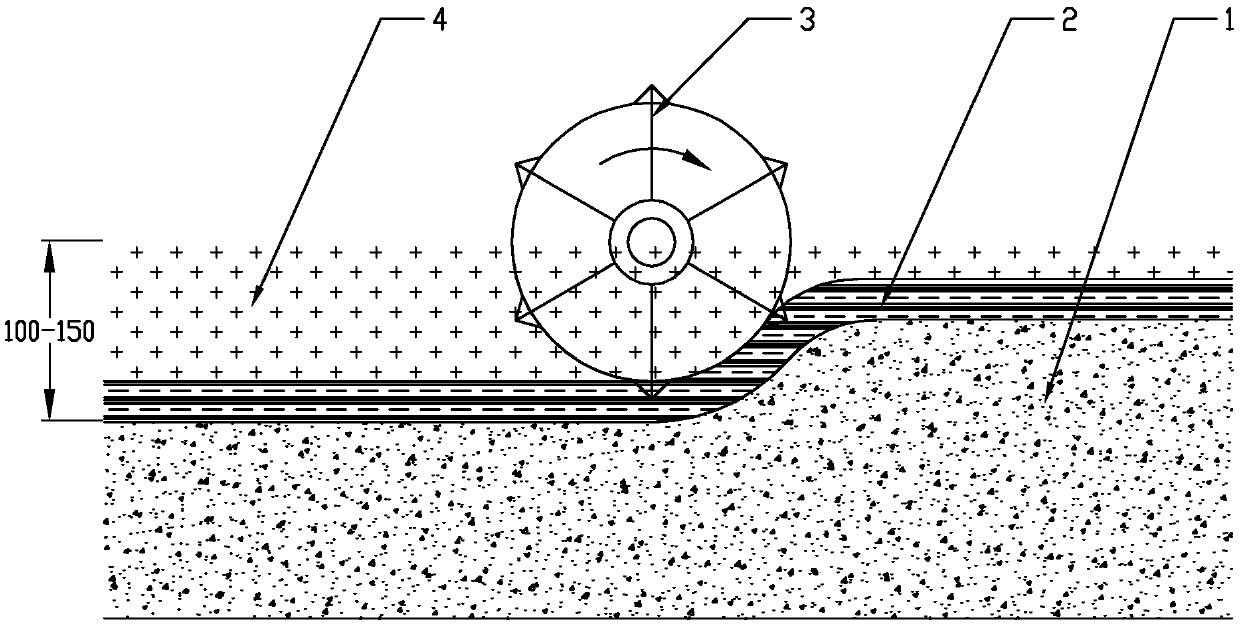

[0023] Embodiment 1: as Figure 1-Figure 3 As shown, the present invention is a farming method for returning the whole straw to the paddy field. The corn stalks 2 are spread on the surface of the paddy field 1 after rotary plowing. 2. The whole plant is pressed into the paddy field soil 1 to complete the operation of returning to the field.

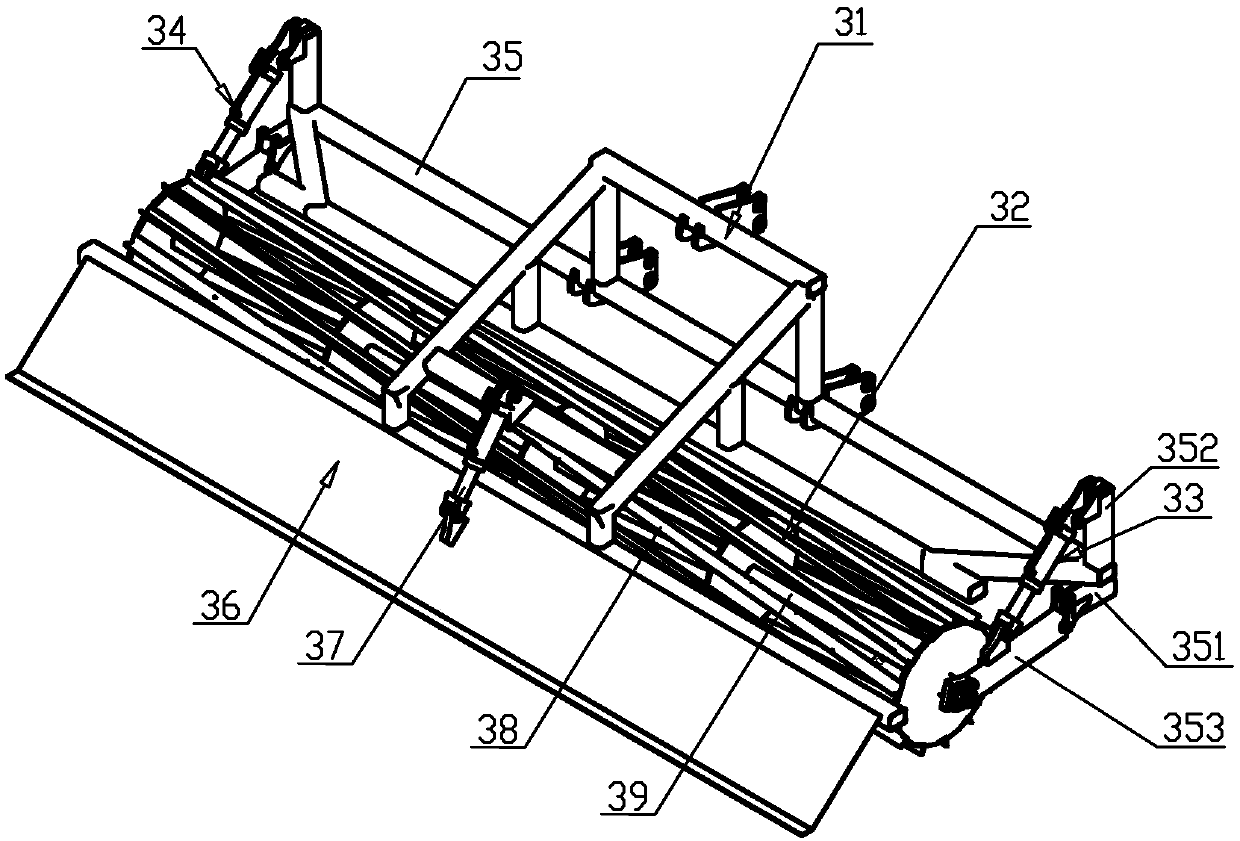

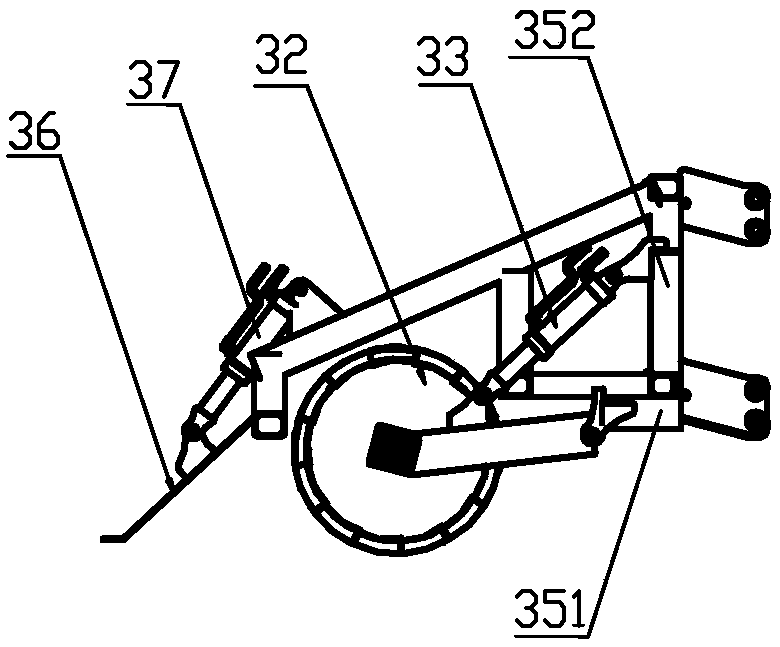

[0024] The rake buried pressure roller device 3 includes a frame 35, a buried pressure roller assembly, a hydraulic cylinder and a hydraulic scraper 36. On the rod 351, the two connecting rods 353 are respectively connected with the hydraulic cylinder I33 and the hydraulic cylinder II34, and the other ends of the hydraulic cylinder I33 and the hydraulic cylinder II34 are connected to the vertical support rod 352 of the frame; The end of the frame 35 of the pressure roller assembly is connected to the hydraulic scraper 36 and the suspension frame 31 above the frame through a hydraulic cylinder III37, and the rotation angle of the hydrauli...

Embodiment 2

[0029] Example 2: The difference between this example and Example 1 is that the inclination angle α between the embedding rib 38 and the roller shaft 39 in this example is 5°, the amount of return to the field is controlled at 7500 kg per hectare, and the corn or rice straw The buried depth is 10cm.

[0030] Example 2: The difference between this example and Example 1 is that the inclination angle α between the buried pressure rib 38 and the roller shaft 39 in this example is 15°, and the amount of return to the field is controlled at 12000 kg per hectare, and corn or rice straw The buried depth is 15cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com