Welding Tooling and Welding Method for Thin-walled Bellows Sheet

A technology for welding tooling and bellows, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as molten pool collapse, welding mushroom asymmetry, poor weld formation, etc., and achieve good repeatability , prevent weld seam collapse, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

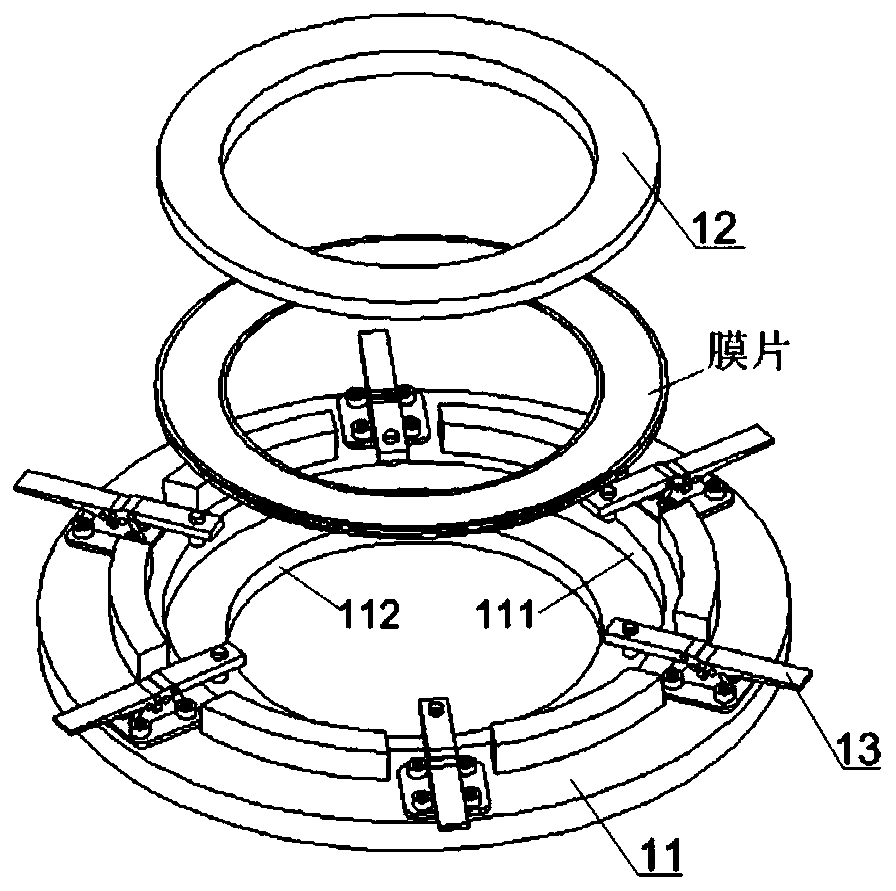

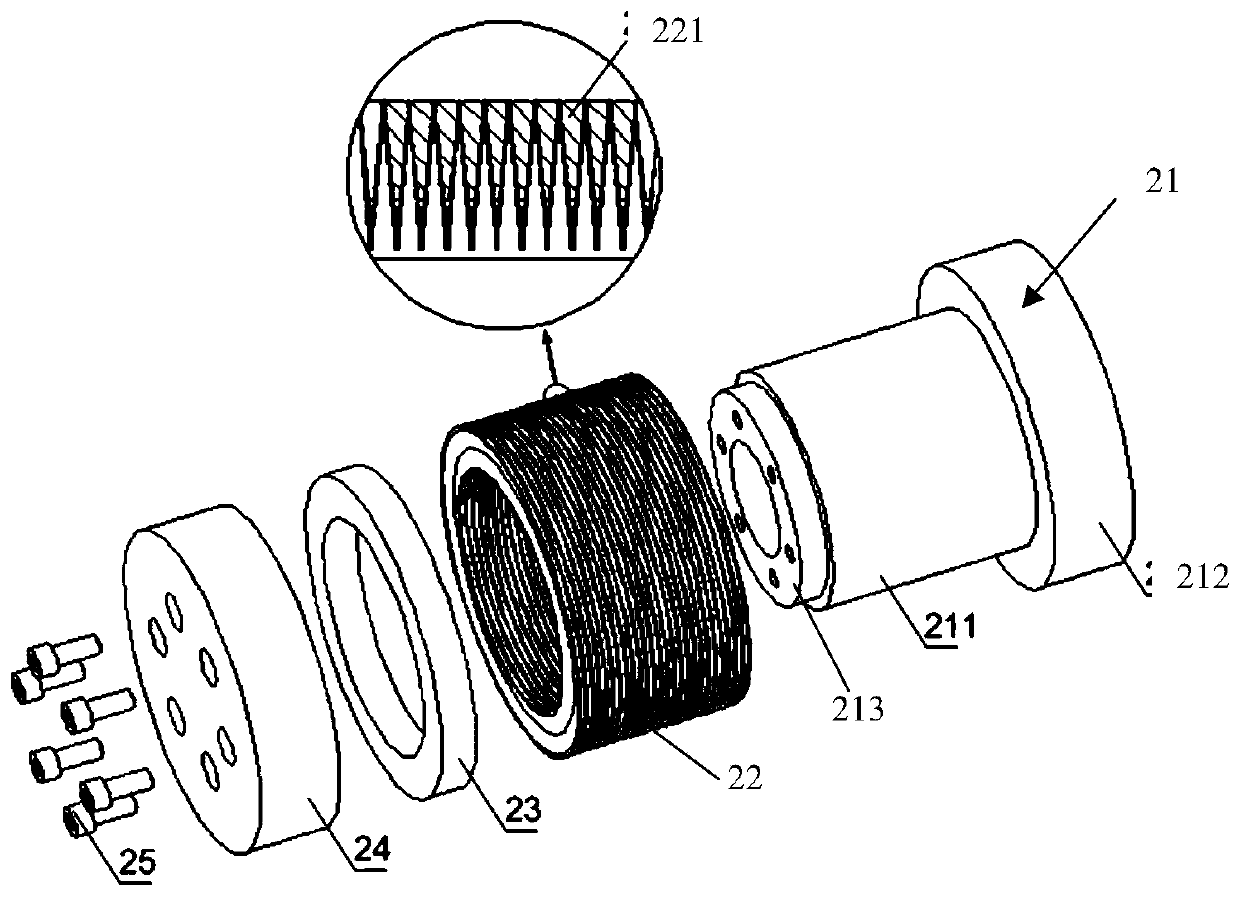

[0014] see Figure 1 to Figure 2 , The welding tooling of the thin-wall bellows diaphragm of the present invention includes an inner circle welding tool 1 and an outer circle welding tool 2 . Inner circle welding tool 1 comprises inner circle welding tool base 11, inner circle welding tool pressing block 12 and elbow clamp 13. The inner circle welding tool base 11 includes a cavity outer circle 111 and a cavity inner circle 112 . The cavity inner circle 112 and the cavity outer circle form a stepped structure. The diaphragm is located on the step formed by the cavity outer circle 111 and the cavity inner circle 112 . Of course, those skilled in the art can understand that the inner circle of the cavity and the outer circle of the cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com