High-efficient cleaning type dissolving apparatus for chemical industry

A dissolving device and chemical technology, applied in the directions of dissolving, dissolving, driving agitator dissolving, etc., can solve the problems of inconvenient use and movement, inconvenient processing and production, limited stirring range, etc., and achieves strong practicability, simple structure and good dissolving effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

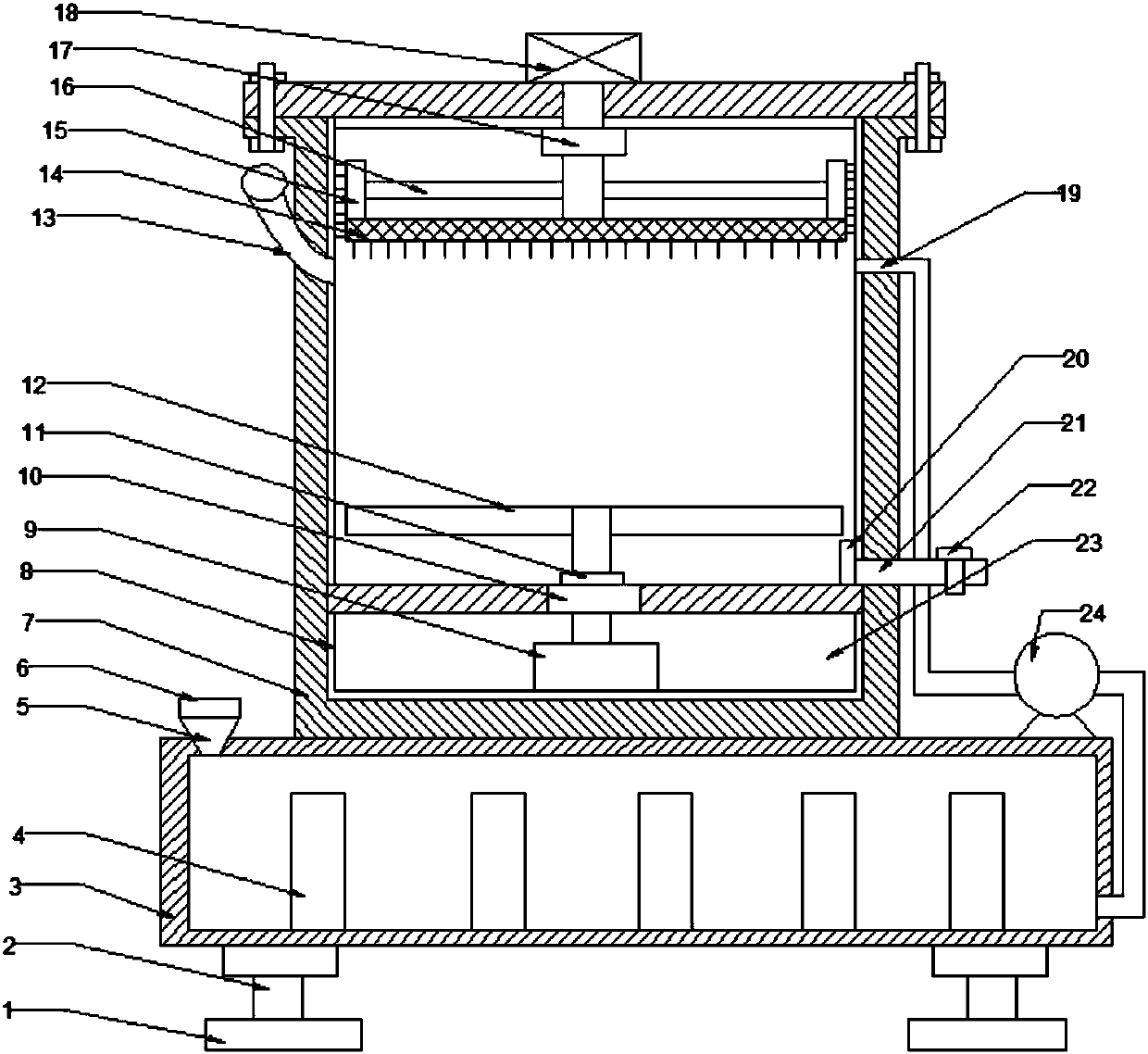

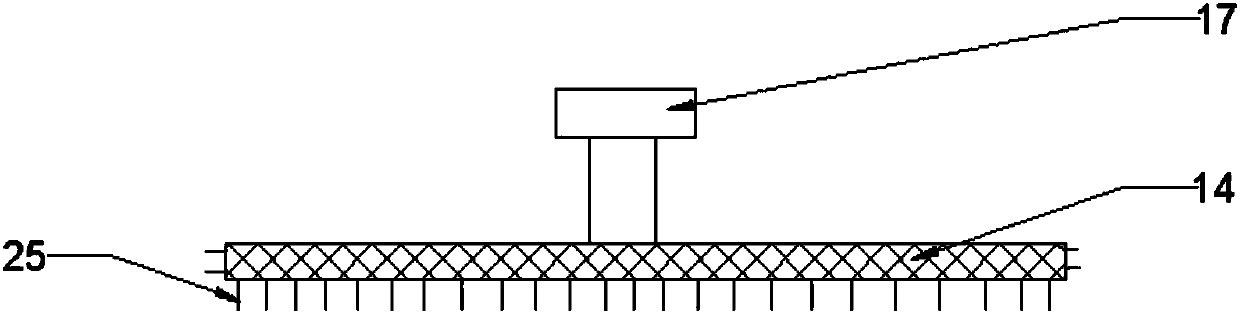

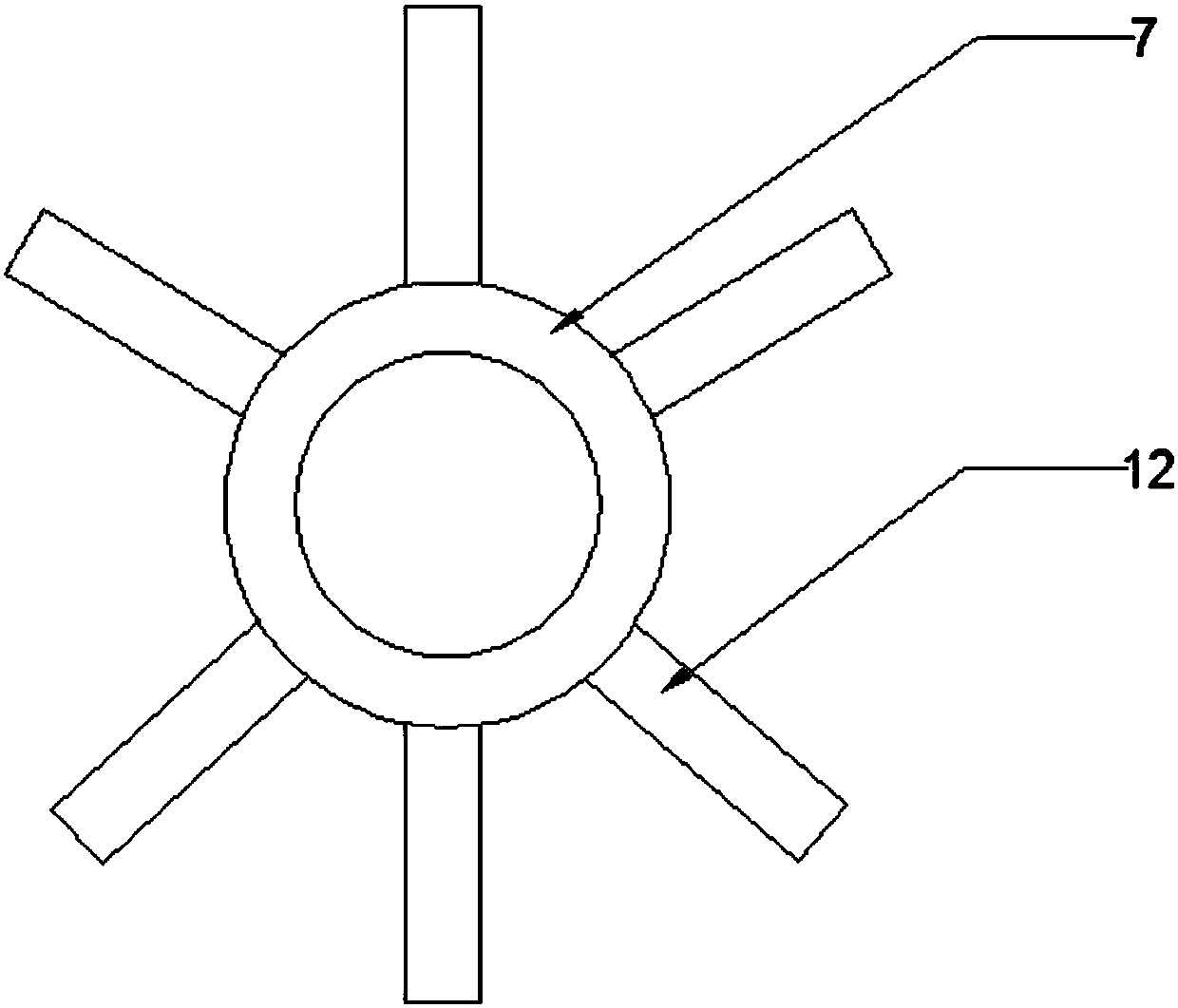

[0016] see Figure 1-3 , a high-efficiency cleaning type chemical dissolution device, including a dissolution device and a cleaning device; Layer 8, first motor 9, waterproof plug 10, first hydraulic telescopic column 11, stirring plate 12, feed pipe 13, water pipe 19, filter plate 20, discharge pipe 21, valve 22, device cavity 23 and water suction pump 24 The support column 2 is arranged on both sides below the water tank 3, and is fixed by welding, and the support column 2 is fixedly provided with an anchor 1; the water inlet funnel 5 is arranged on the upper left side of the water tank 3, and the water inlet funnel 5 A sealing cover 6 is arranged on the top of the water tank, which has the function of dustproof; the heating rod 4 is fixedly arranged on the inner cavity bottom surface of the water tank 3, and has the function of heating water; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com