Steel pipe cutting and unloading device

A technology of cutting device and pushing device, which is applied in the direction of pipe shearing device, shearing device, shearing machine equipment, etc., can solve the problem that workpiece cutting is easy to be damaged, and achieve rationality of guarantee, reasonable design of overall structure, and prevention of damage damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

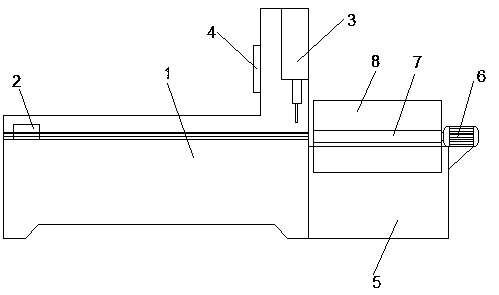

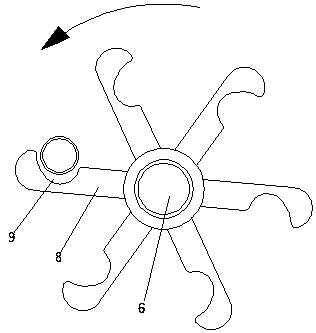

[0016] Below in conjunction with specific embodiment, content of the present invention is described in further detail: as Figure 1-2 As shown, a steel pipe cutting and blanking device includes a workbench 1, a pushing device 2 and a cutting device 3 arranged on the workbench 1, wherein the side of the workbench 1 close to the cutting device 3 has a material receiving device , the material receiving device includes a material box 5, a motor 6 fixed on the material box 5, a rotating shaft 7 connected to the motor 6, and some material receiving plates 8 evenly arranged on the rotating shaft 7; the central axis of the rotating shaft 7 is arranged along the horizontal direction, The direction of the long axis of the material receiving plate 8 is parallel to the direction of the central axis of the rotating shaft 7 , and a groove 9 is formed on the end surface of the side opposite to the direction of rotation.

[0017] As a further optimization of this embodiment, the height of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com