Liquefied petroleum gas test copper strip polishing device

A technology of liquefied petroleum gas and polishing device, which is applied in the direction of grinding drive device, surface polishing machine tool, grinding/polishing equipment, etc., can solve the problems of low efficiency, poor quality consistency, labor and time-consuming, etc. Good consistency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific examples.

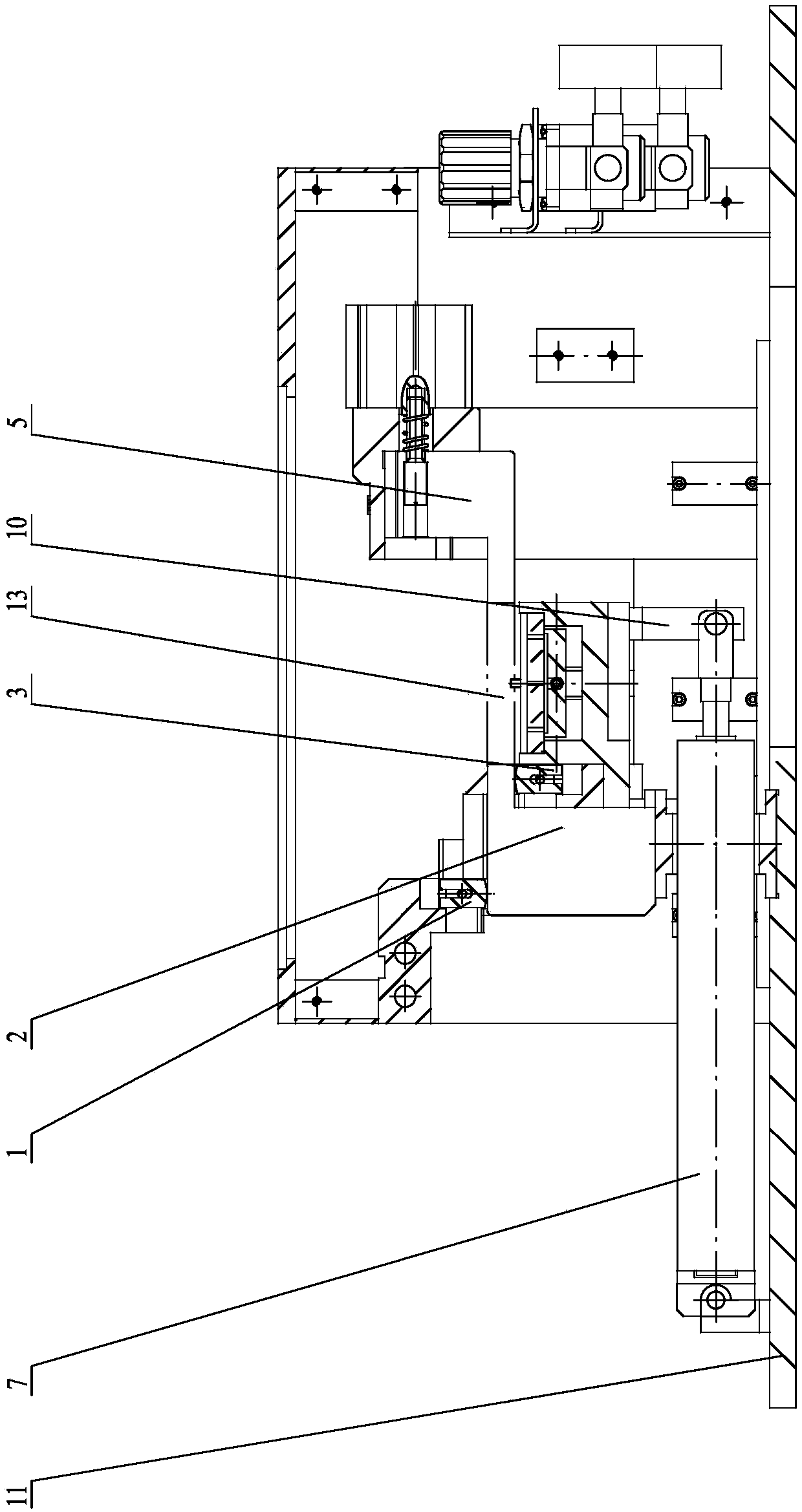

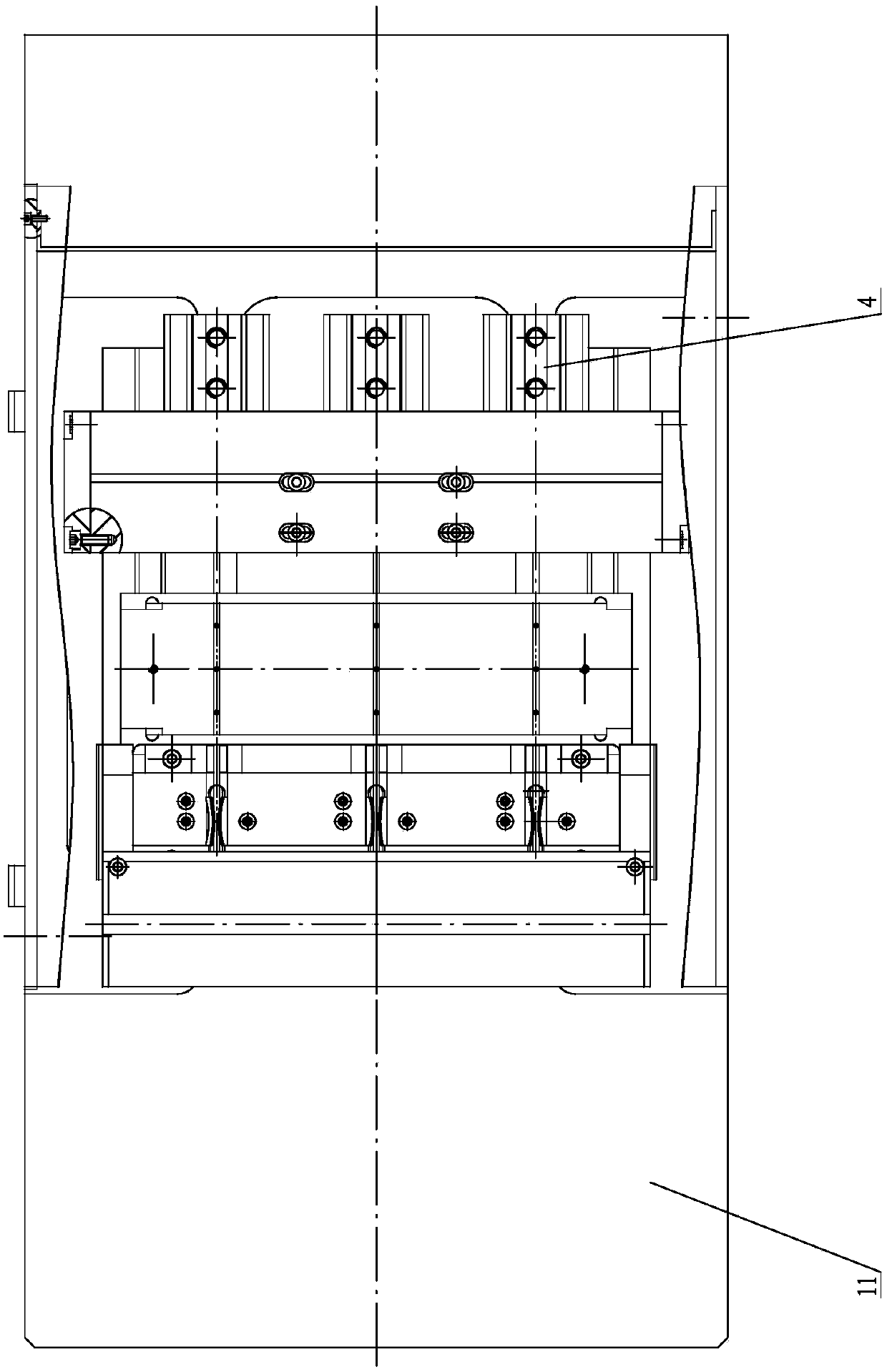

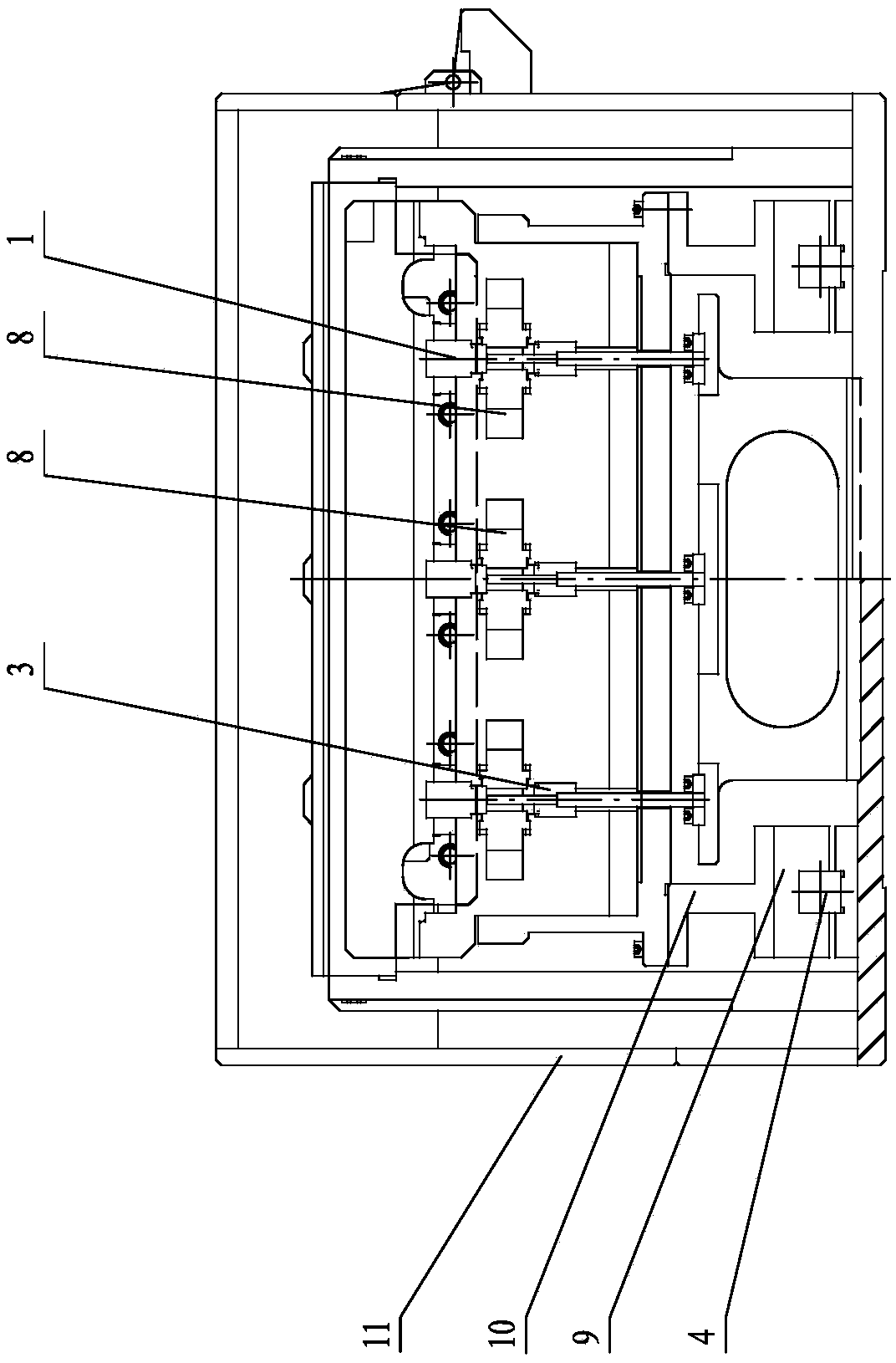

[0011] The liquefied petroleum gas test copper polishing device includes an upper side grinding head 1, a fixed fixture 2, a lower side grinding head 3, a linear guide rail 4, a movable fixture 5, a clamping cylinder 6, a pushing cylinder 7, and a side grinding head 8 , slide block 9, grinding head mounting seat 10 and polishing frame 11; On polishing frame 11, linear guide rail 4, fixed fixture 2 and clamping cylinder 6 are fixed, slide block 9 is installed on linear guide rail 4, and The slider 9 is fixed with a grinding head mounting seat 10, and the upper side grinding head 1, the lower side grinding head 3 and the left and right side grinding heads 8 are fixed on the grinding head mounting seat 10, and the piston rod end of the clamping cylinder 6 Movable clamp 5 is fixed at the top, and movable clamp 5 cooperates with fixed clamp 2, is hinged on the polishing machine fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com