Connecting device for cab and car frame

A connecting device and cab technology, which is applied to the upper structure of trucks, vehicle parts, transportation and packaging, etc., can solve the problems of complex structure of Y-direction stabilizing mechanism, occupying a large space, and arranging many parts, and achieve the overall Effects of weight and cost control, small footprint, and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

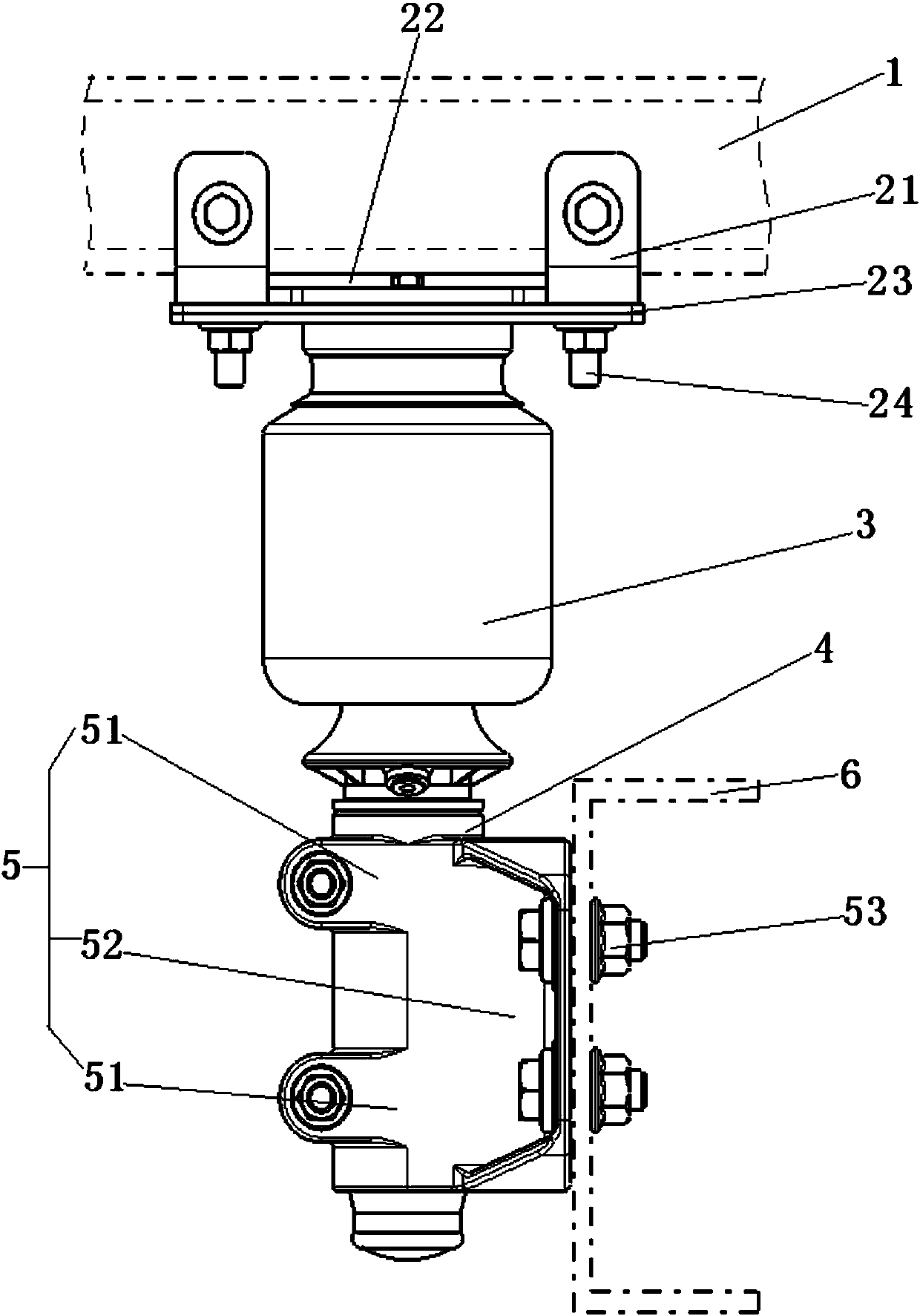

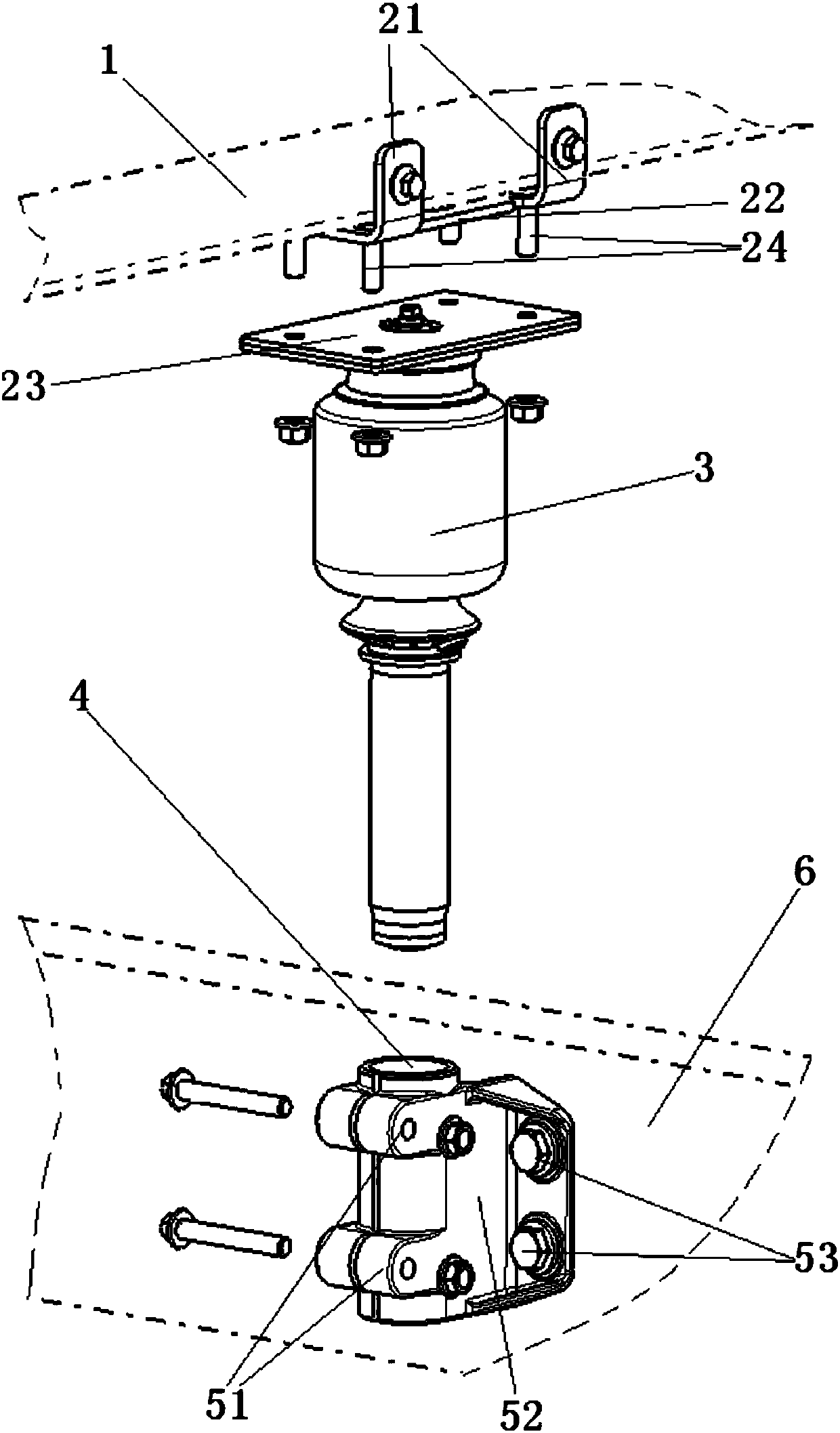

[0025] Such as figure 1 shown, see also figure 2 , the embodiment of the present invention provides a connection device between the cab and the vehicle frame, including a first mounting frame 21, a spring damper 3, a second mounting frame 5, and a mounting cylinder 4, and the first mounting frame 21 is fixed on On the floor sheet metal 1 of the cab, the spring shock absorber 3 is vertically arranged, the spring shock absorber 3 is located below the floor sheet metal 1, and the top of the spring shock absorber 3 is fixedly connected to the first mounting frame 21 , the second mounting frame 5 is fixedly connected with the vehicle frame 6, the mounting tube 4 is vertically fixed on the second mounting frame 5, the bottom of the spring damper 3 extends into the mounting tube 4, and the spring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com