Full-automatic online cantilever wrapping machine

A packaging machine, fully automatic technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of automatic winding of packaging film and EPE corner protector, improve the operability of the equipment, reasonable structure, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

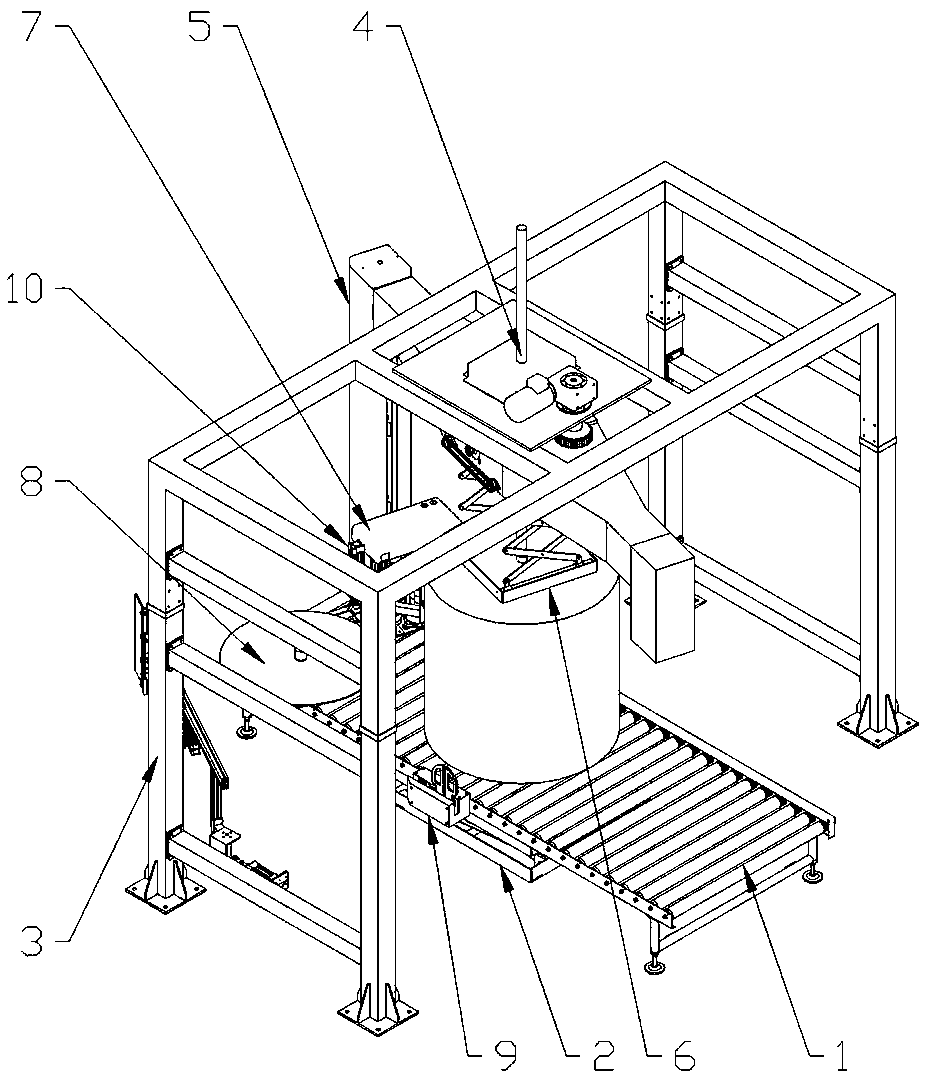

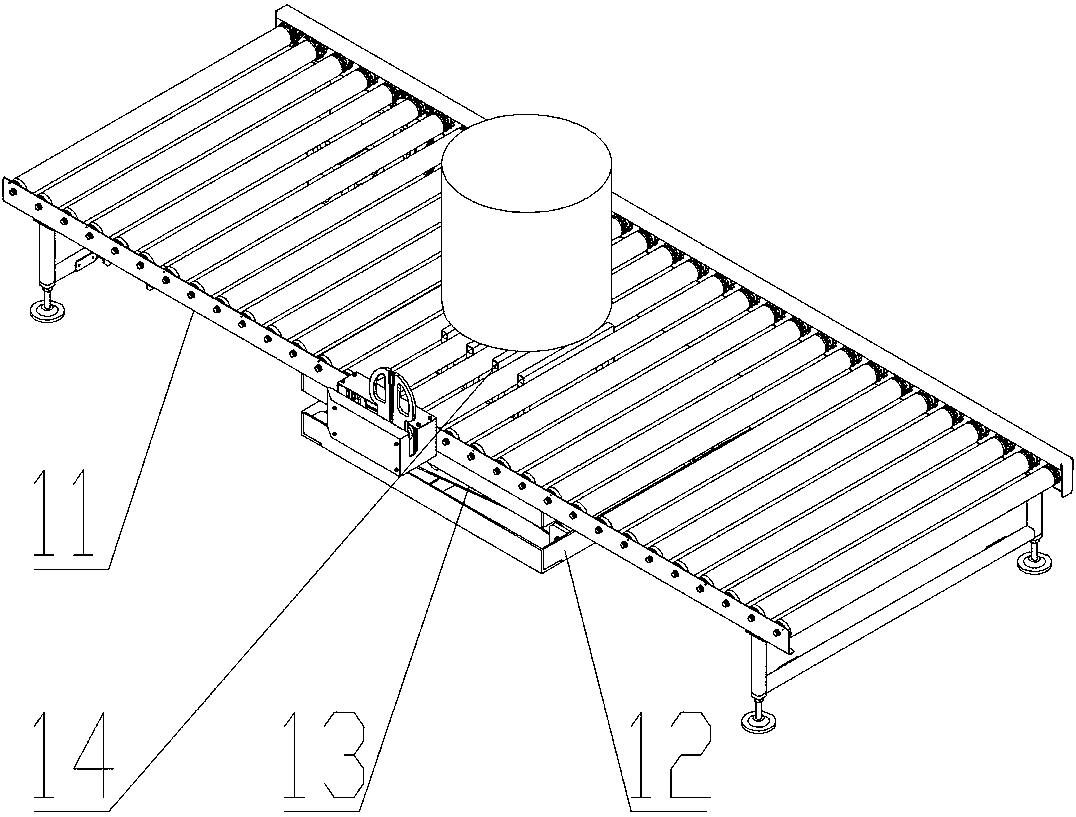

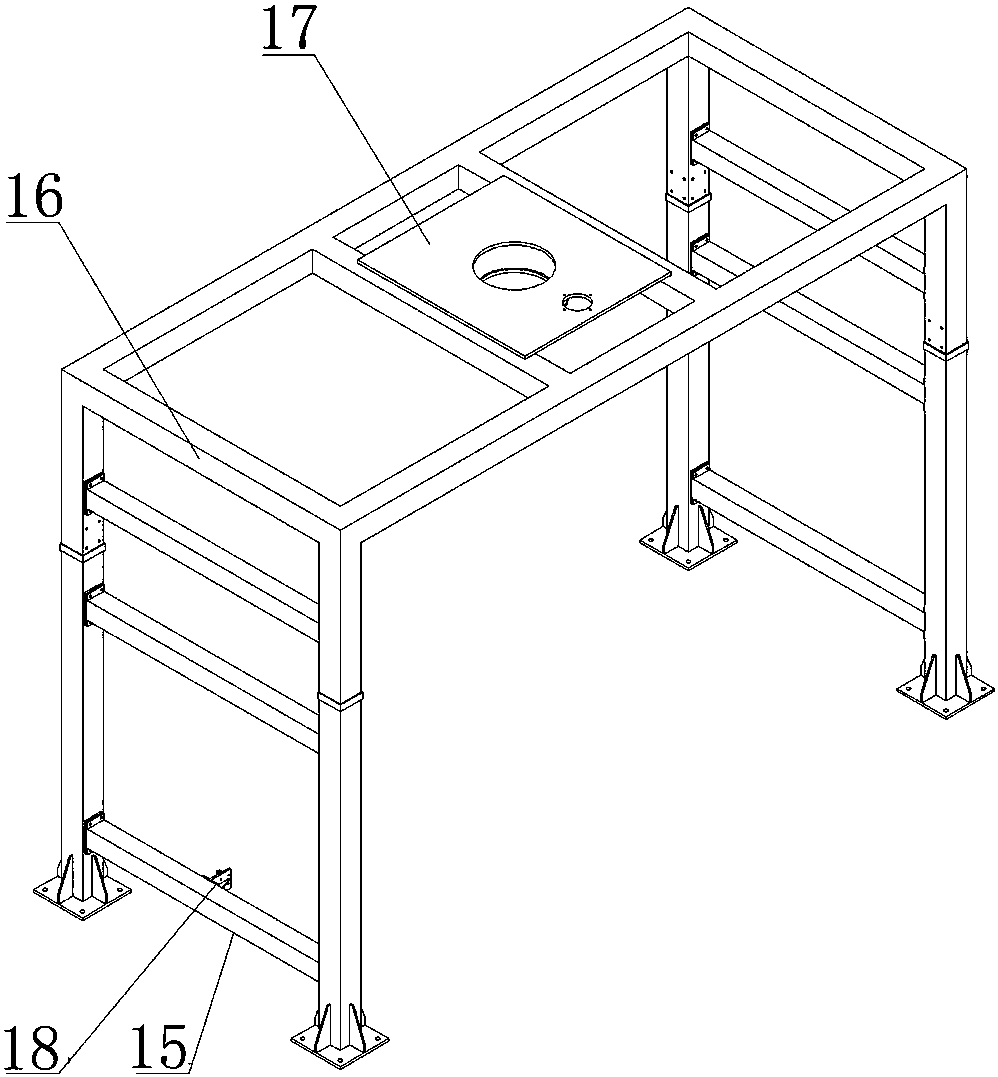

[0017] like Figure 1 to Figure 5 As shown, the fully automatic cantilever online winding packaging machine includes a roller conveyor 1, a jacking mechanism 2, a frame 3, a rocker drive device 4, a film frame lifting device 5, a top pressing mechanism 6, a film film frame device 7, a pearl Cotton film frame device 8, automatic upper film breaking mechanism 9 and automatic upper breaking pearl cotton mechanism 10, jacking mechanism 2 are installed below the roller conveyor 1, and the rocker arm drive device 4 is installed on the top of the frame 3, and the mold frame The lifting device 5 is installed on one side of the rocker arm drive device 4, the film formwork device 7 and the pearl cotton formwork device 8 are respectively installed on the formwork lifting device 5, and the top pressing mechanism 6 is installed on the rotary disk of the rocker arm drive device 4 , the automatic film breaking mechanism 9 is installed on the side beam of the roller conveyor 1, the automatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com