Automatic labeling device for packaging box

A packaging and labeling technology, applied in packaging, labeling machines, transportation and packaging, etc., can solve the problems of inconvenient operation and complex structure of the labeling device, and achieve the effects of convenient operation, saving manpower and material resources, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

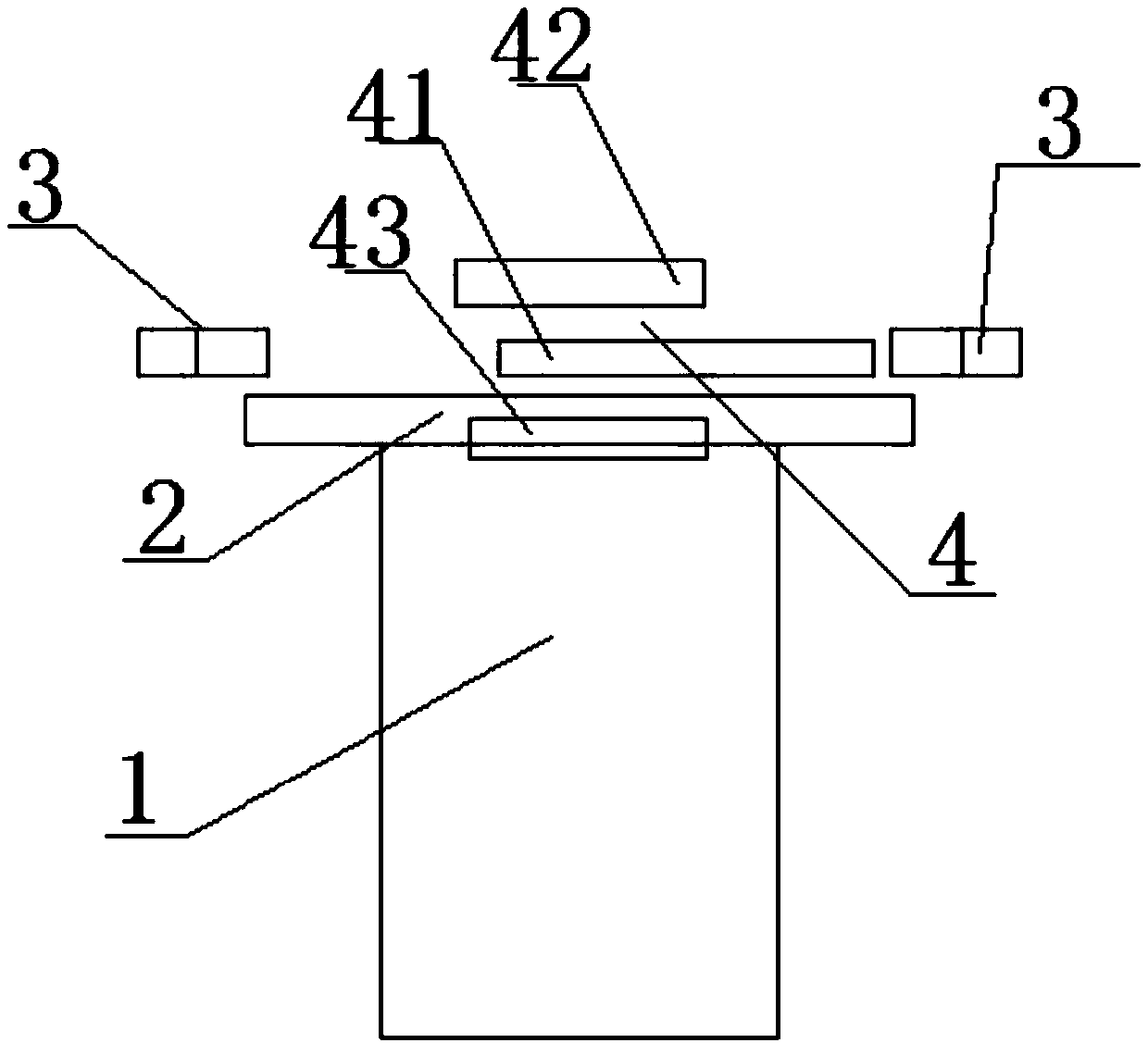

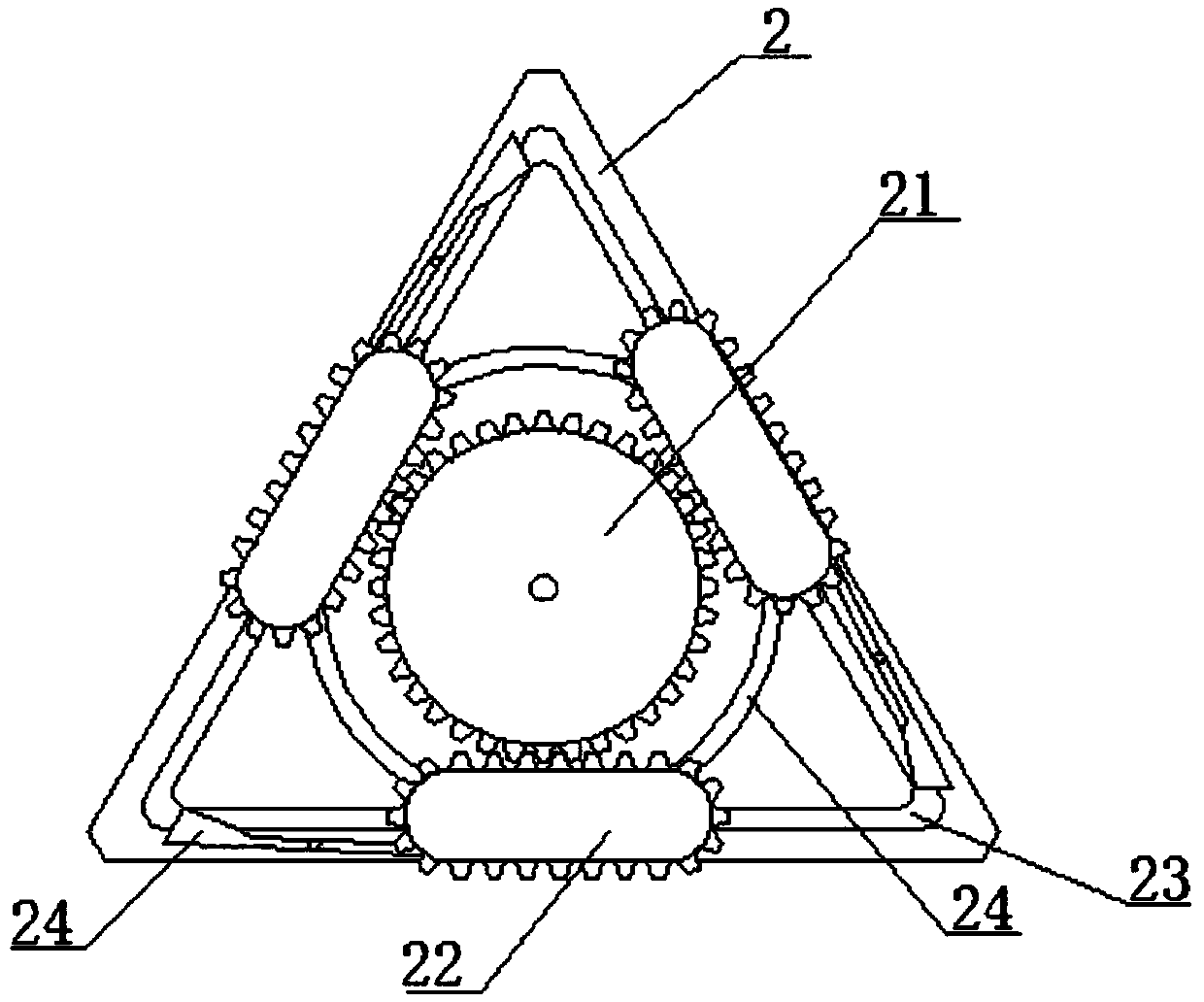

[0031] Such as Figure 1-Figure 7 As shown, an automatic labeling device for packaging boxes includes a base 1, and the base 1 is provided with a motor. The upper surface of the base 1 is provided with a triangular work surface 2. 21 is connected to the output shaft of the motor, and the working track is provided with a working track on the working track, and a rotating table 22 is arranged on the working track, and the periphery of the rotating table 22 is provided with gear teeth meshed with the driving gear 21, and the working track includes intersecting peripheral tracks 23 and The inner track 24, the outer track 23 includes three straight tracks 231, an arc track 232 is arranged between two adjacent straight tracks 231, and the straight track 231 and the arc track 232 form a closed triangular track. The surrounding track 24 is a circular track, and the circular track and the straight track 231 form an intersection at the middle part of the straight track 231. A guide rod ...

Embodiment 2

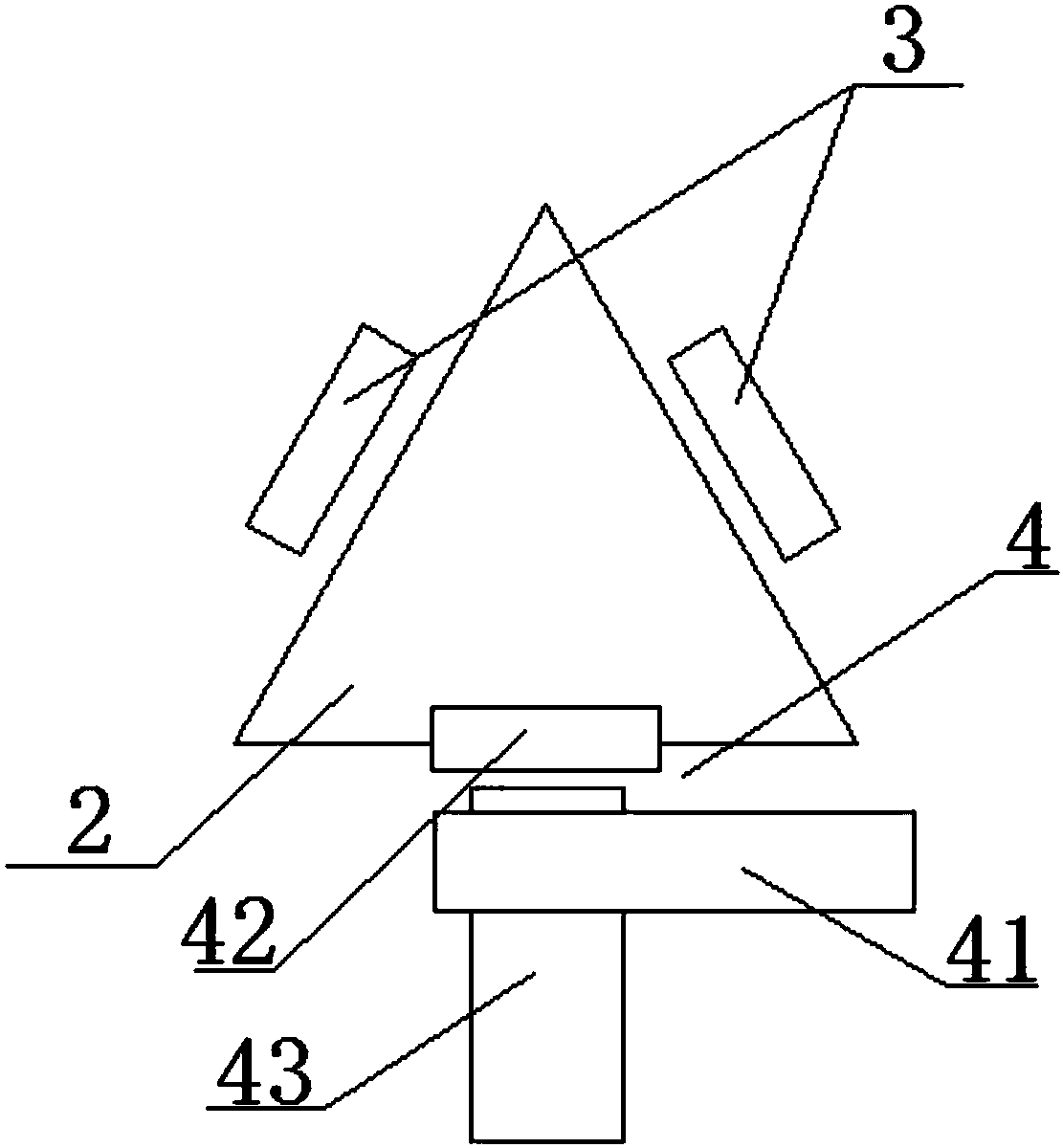

[0033] On the basis of Embodiment 1, the described loading and unloading box device 4 includes a feeding conveyor belt 41, a manipulator unloading device 42, and a discharging conveyor belt 43. The unloading device 42 is arranged above the corresponding straight track 231 , and the unloading conveyor belt 43 is arranged under the outer side of the corresponding straight track 231 .

Embodiment 3

[0035] On the basis of Embodiment 1 or 2, the manipulator removal device 42 includes a clamping device 421, and the clamping device 421 is sequentially connected with an inclination adjustment device 422, a horizontal reciprocating device 423, and a vertical lifting device 424. A clamping part 4211 is provided at the bottom of the fetching device 421, and when the clamping part 4211 is closed, one side forms a plane for pushing the box.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com