Sustained energy bake stable fillers and baked products comprising these

A technology of filling and filling components, which is applied in the direction of baking mixture, baked food, baked food with modified ingredients, etc., which can solve the problems of not being a consumer, not expected from the perspective of commercial preparation, and time-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

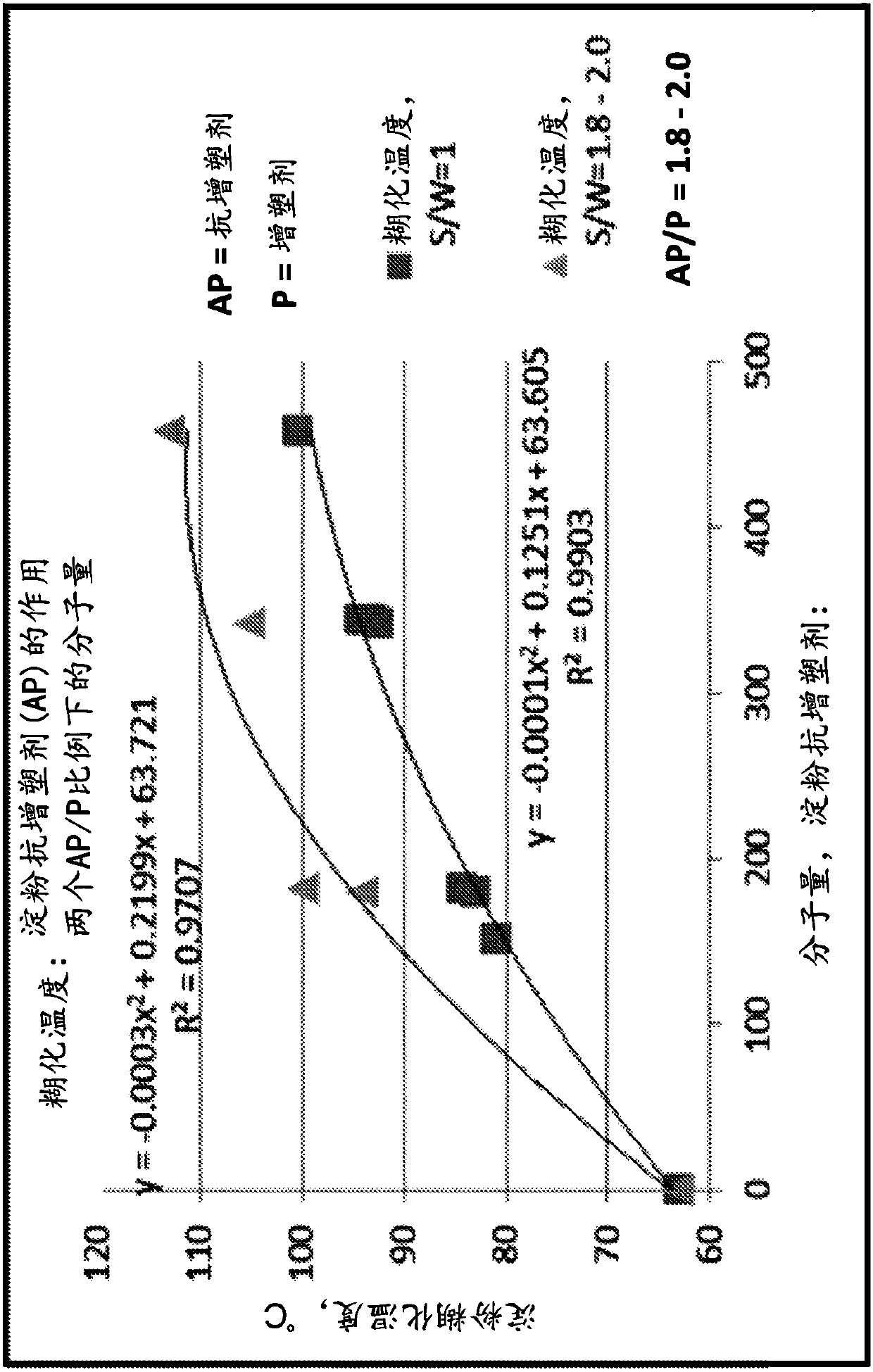

[0071] figure 1 Shows the molecular weight of starch antiplasticizer in excess solution (that is, starch solids greater than or equal to 50%), the antiplasticizer concentration expressed in the ratio of antiplasticizer / water, and wheat starch (Aytex P, ADM ) The relationship between the gelatinization temperature obtained in the excess solution (that is, about 50% starch solids, 1 part starch plus 1 part sugar-water co-solvent). In this embodiment, water is added to the starch plasticizer, and the starch anti-plasticizer is fructose, glucose, sucrose, polydextrose and other sugars. In this figure, two ratios of anti-plasticizer to water are shown: AP / W=1, AP / W=1.8 to 2.0. As shown in the figure, the gelatinization temperature increases with the increase of sugar molecular weight and concentration, indicating that the anti-plasticizing effect of sugar is replaced by the increase of sugar concentration with the increase of molecular weight and water. The relationship is quasi-li...

Embodiment 2

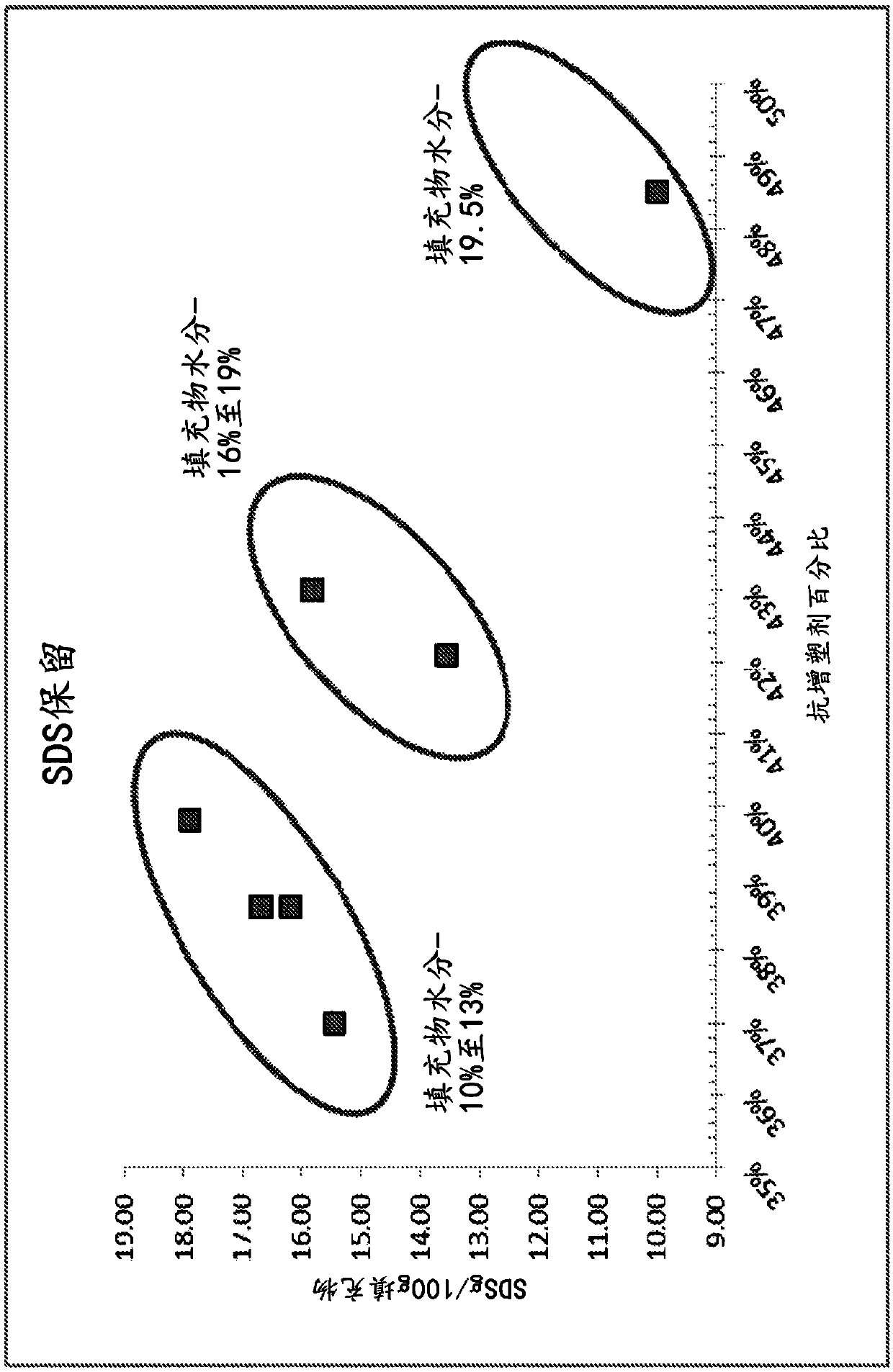

[0077] figure 2 The effect of SDS retention based on the moisture content of the filler and the percentage of starch antiplasticizer in the filler is shown. For these experiments, the starch was wheat starch (Aytex P, ADM), the starch plasticizer was water and / or glycerin, and the starch antiplasticizer was a combination of fructose, glucose and sucrose, with 60% of the molecular weight of the antiplasticizer The molecular weight of 180 and 40% is 342, the molecular weight of the antiplasticizer is reduced to 33% is 180 and the molecular weight of 67% is 342.

[0078] Apple-based filling

ingredient

weight

total weight

% "As is" composition

DWT

Target dough temperature-67F

Filler sugar-glucose

10.7

10.7%

Filling sugar-fructose

10.9

10.9%

Filler sugar-sucrose

13.7

13.7%

water

11.4%

Other (pectin, etc.)

7.7%

Total filling

54.35

21.00%

42.9

[0079] The above table includes the sugar composition of the "apple filling" ingredients used to prepare the SDS fruit ...

Embodiment 3

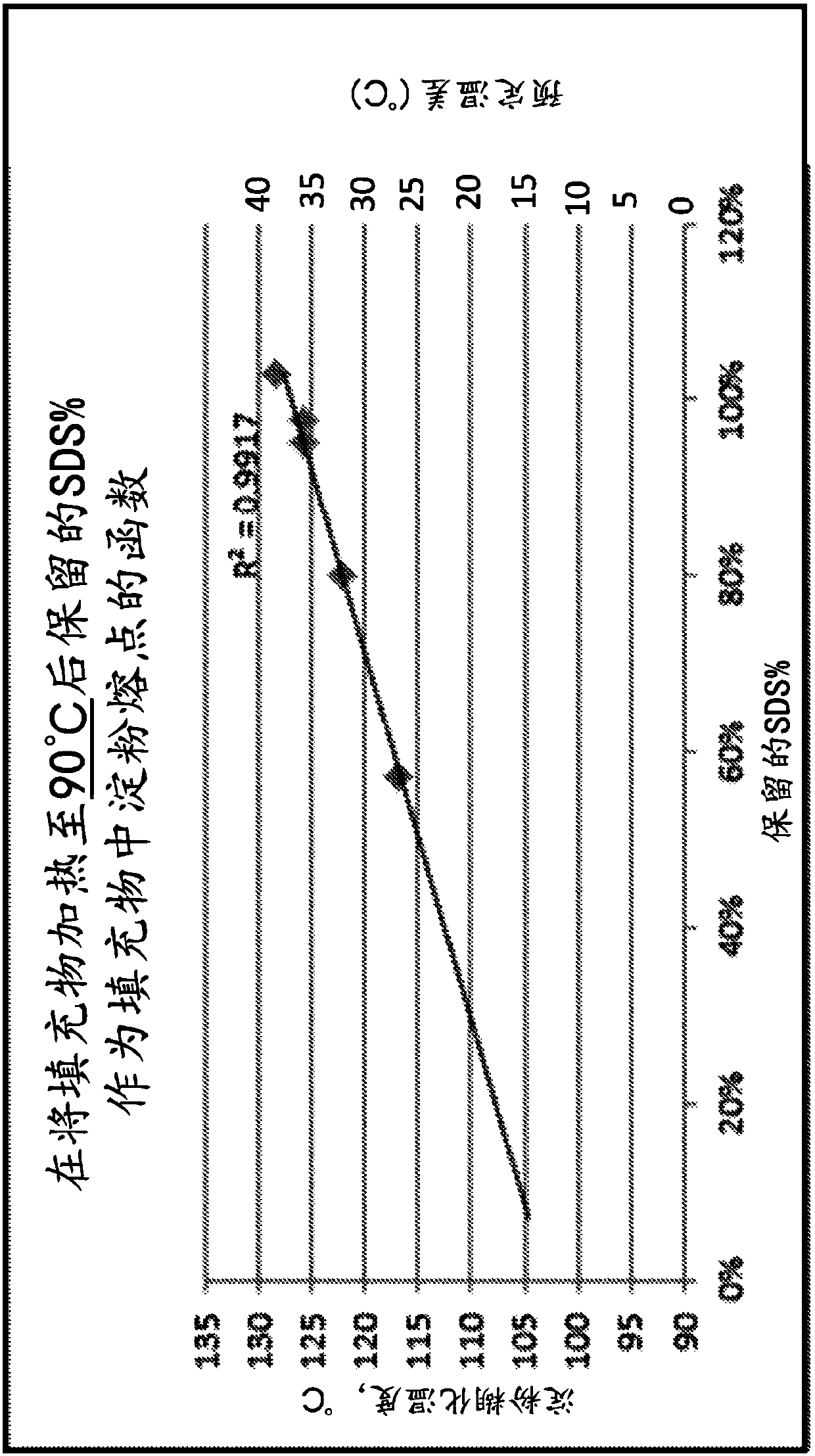

[0084] image 3 It shows the retention of slowly digestible starch when the starch gelatinization temperature (affected by sugar and antiplasticizer concentration) exceeds the filling processing temperature that helps retain high levels of SDS.

[0085] The baking temperature is about 90°C.

[0086] The following table shows the composition of SDS fruit filling, including apple filling ingredients, wheat starch, water, sugar (liquid and dry), glycerin, total filling moisture, and SDS content before and after heating to 90°C (standardized to 36%) SDS content by weight), SDS retention% after heating, total sugars, and gelatinization temperature of starch in the filling measured by DSC.

[0087]

[0088] This shows that the higher starch gelatinization temperature in the filling can stabilize the starch and increase the retention of SDS.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com