Reflow oven liner with a substrate and an adhesive layer, and a method for treating the surface of a reflow oven

A reflow oven, adhesive technology, applied in the field of reflow oven liner with substrate and adhesive layer and used to treat the surface of reflow oven, can solve uneven application, messy, difficult to apply, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

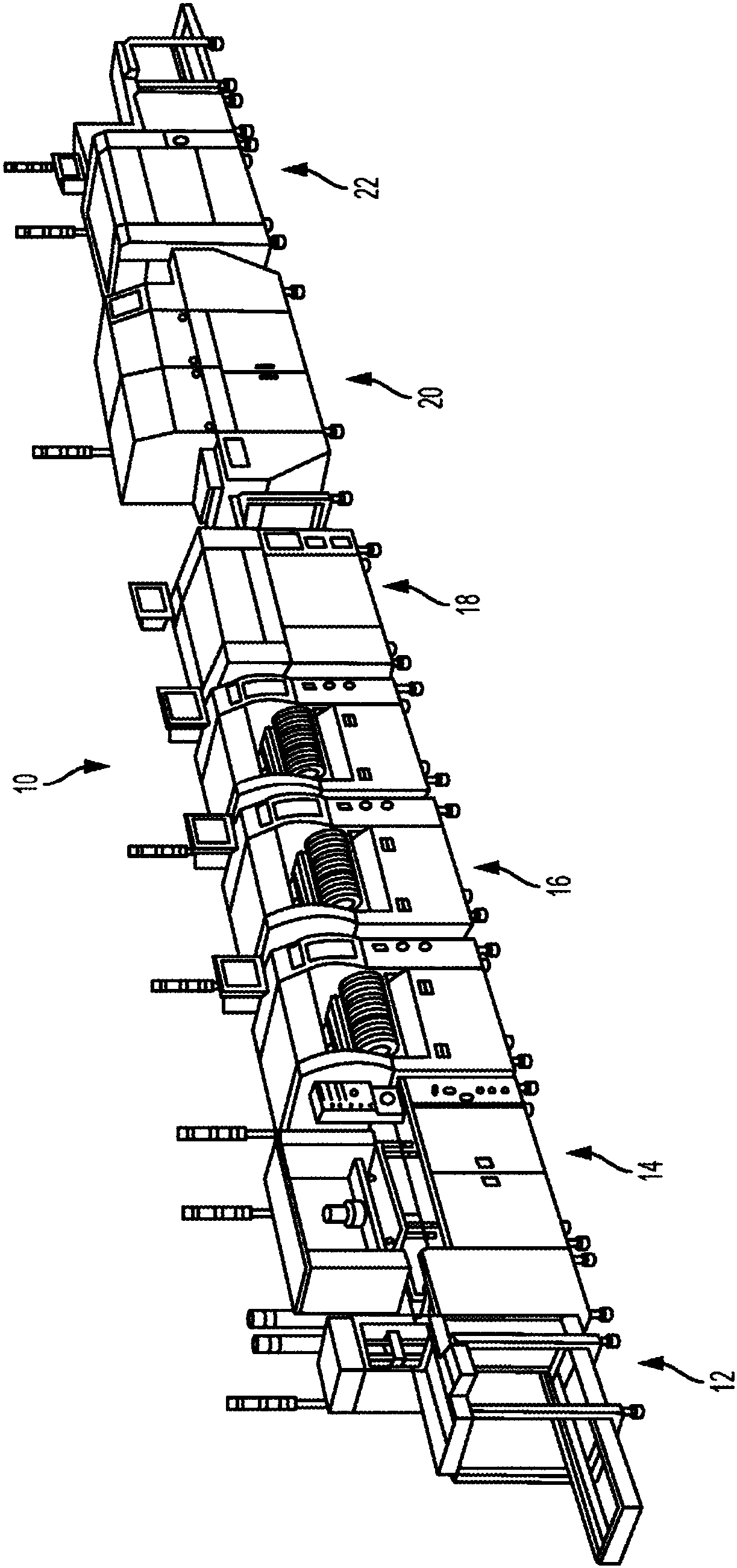

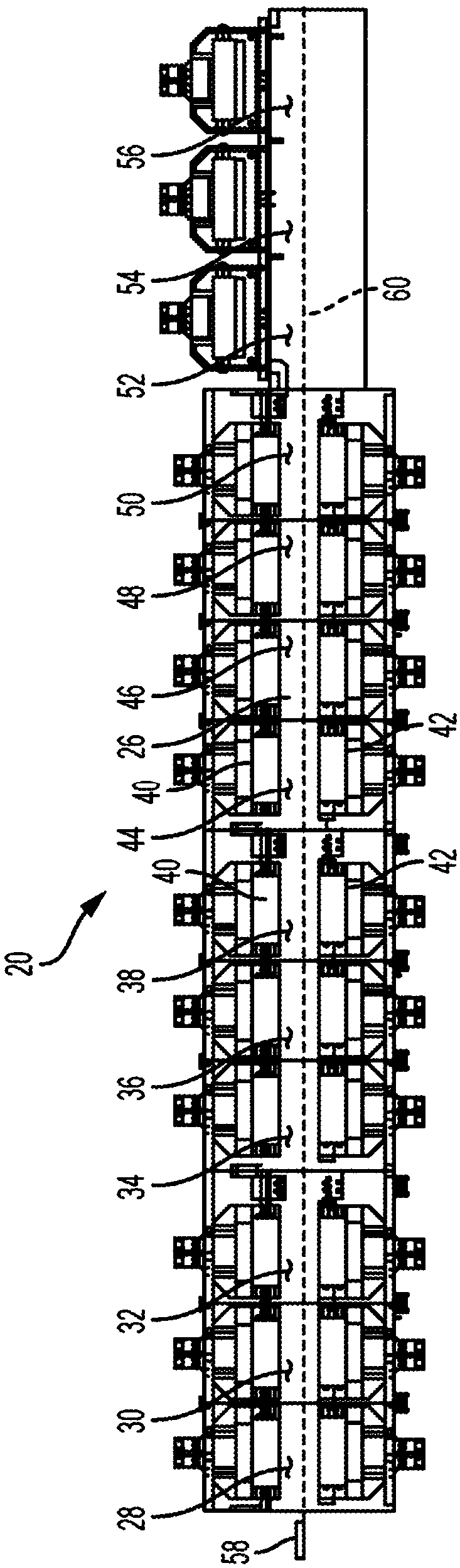

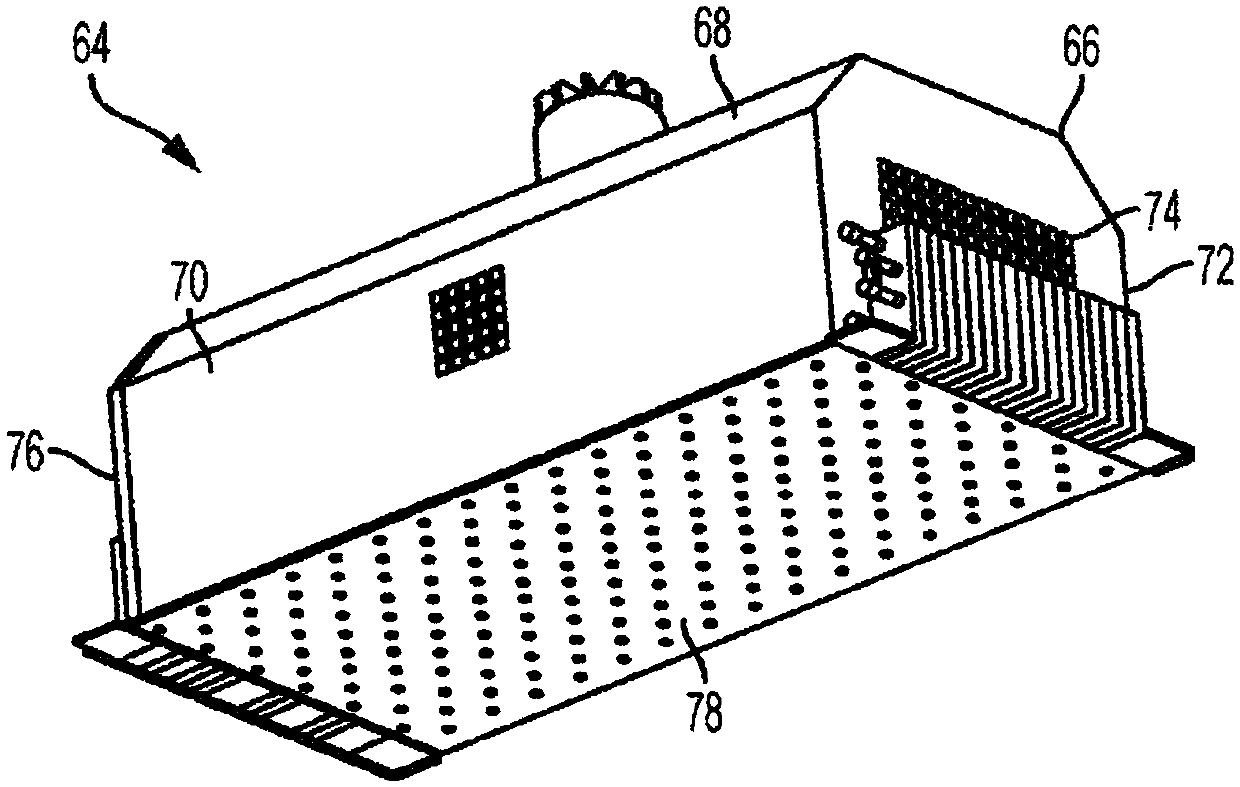

[0031] While the device is amenable to embodiments in many forms, a presently preferred embodiment is shown in the drawings and will hereinafter be described, it being understood that the disclosure is considered an example of a device and is not intended to be limited to the particular ones shown. Example.

[0032] Solder paste is commonly used in the assembly of printed circuit boards, where the solder paste is used to bond electronic components to the circuit board. Solder paste includes solder for joint formation and flux for preparing metal surfaces for solder attachment. Solder paste may be deposited on metal surfaces (eg, electronic pads) provided on a circuit board using any number of application methods. The leads of the electronic components are aligned with and stamped into the solder deposited on the pads to form the assembly. During the solder reflow process, the solder is then heated to a temperature sufficient to melt the solder and cooled to permanently (elec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap