Multi-fuel engine apparatus

An internal combustion engine and multi-fuel technology, applied to combustion engines, internal combustion piston engines, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

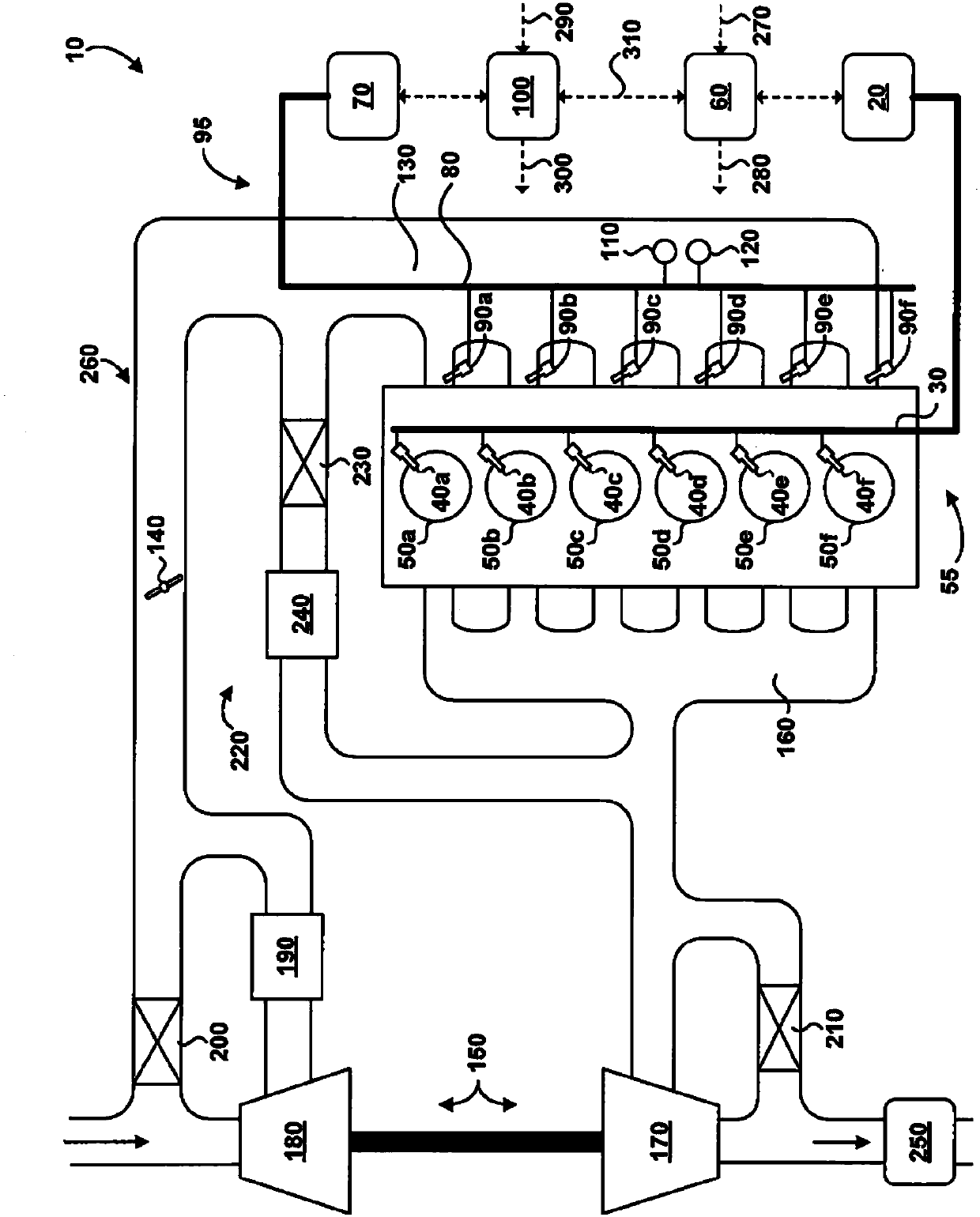

[0020] refer to figure 1is a schematic illustration of a multi-fuel engine 10 according to an embodiment in which an engine originally designed to run on liquid fuels has been adapted to additionally or alternatively run on gaseous fuels. Liquid fuel supply 20 delivers liquid fuel to liquid fuel rail 30 at a pressure suitable for post-cycle direct injection into combustion chambers 50a-50f (collectively 50a-f). Late cycle direct injection refers to the introduction of fuel directly into the combustion chamber late in the compression stroke. Alternatively or additionally, in other embodiments, liquid fuel supply 20 may deliver liquid fuel to rail 30 at a pressure suitable for early cycle direct injection. Liquid fuel injectors 40a-40f (collectively 40a-f) are in fluid communication with the liquid fuel rail, and when commanded by electronic controller 60, liquid fuel injectors 40a-40f introduce liquid fuel directly into respective combustion chambers 50a-f . Liquid fuel syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com