Spliced type large-specification foam aluminum plate and machining method thereof

A foamed aluminum board, large-scale technology, applied in the field of foamed aluminum board, can solve the problems of high cost, inconvenient on-site installation, complicated process, etc., and achieve the effect of low cost, simple installation and high overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

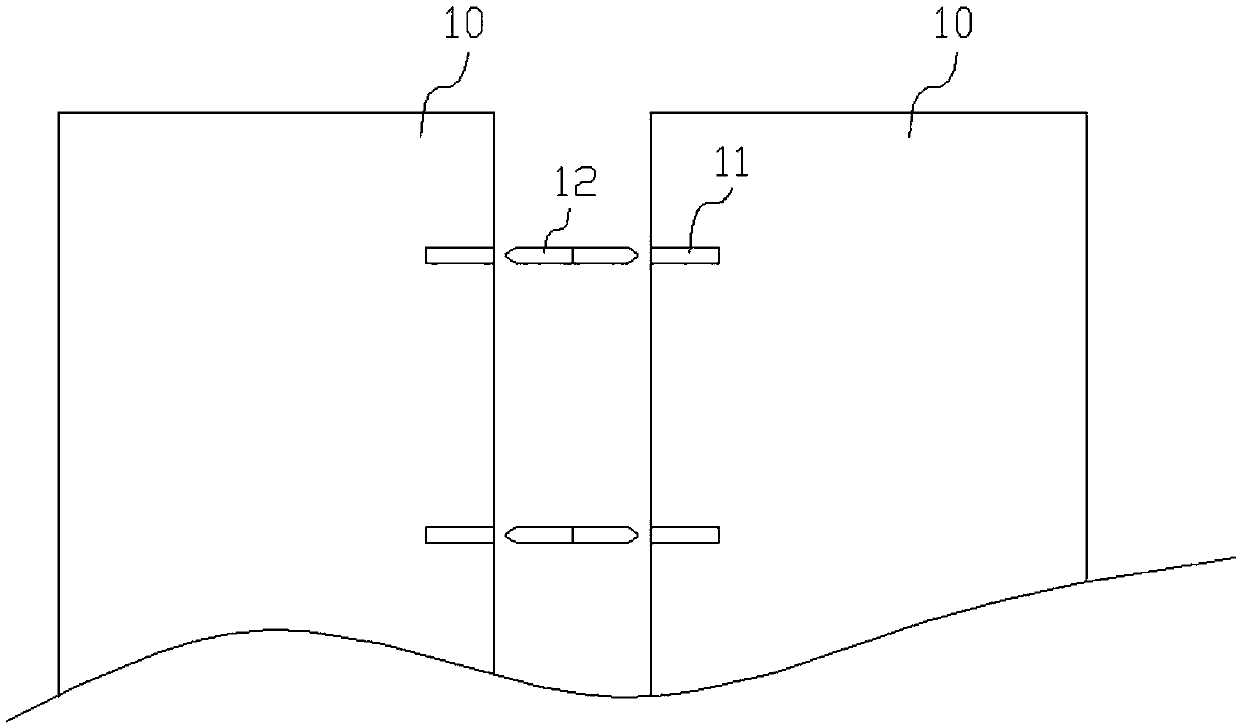

[0028] like figure 1 , figure 2 As shown, an assembled large-sized aluminum foam board is formed by splicing a plurality of foamed aluminum boards 10 of specified size through connectors (steel pins) 12. On the side of the foamed aluminum board 10, the A hole 11 is drilled in the axial direction. When two foam aluminum sheets 10 are connected, the connecting piece 12 is inserted into the corresponding hole 11 of the foam aluminum sheet 10, thereby connecting the two sheets together to play a reinforcing role, so that the foam The overall strength of the aluminum plate 10 is enhanced. The joints between the two aluminum foam plates 10 are filled with adhesive to provide overall strength and sealing performance.

Embodiment 2

[0030] like figure 1 , figure 2 As shown, an assembled large-sized aluminum foam board is formed by splicing a plurality of foamed aluminum boards 10 of specified size through connectors (steel pins) 12. On the side of the foamed aluminum board 10, the A hole 11 is drilled in the axial direction. When two foam aluminum sheets 10 are connected, the connecting piece 12 is inserted into the corresponding hole 11 of the foam aluminum sheet 10, thereby connecting the two sheets together to play a reinforcing role, so that the foam The overall strength of the aluminum plate 10 is enhanced. The joints between the two aluminum foam plates 10 are filled with adhesive to provide overall strength and sealing performance. Ceramic balls are arranged inside the foamed aluminum plate 10 , and the ceramic balls are sealed inside the foamed aluminum plate 10 , and the ceramic balls are not in contact with each other. The ceramic balls are added during the foaming process of the foamed alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com