Method and device for pulse composite magnetic field assisted GMAW high-speed welding

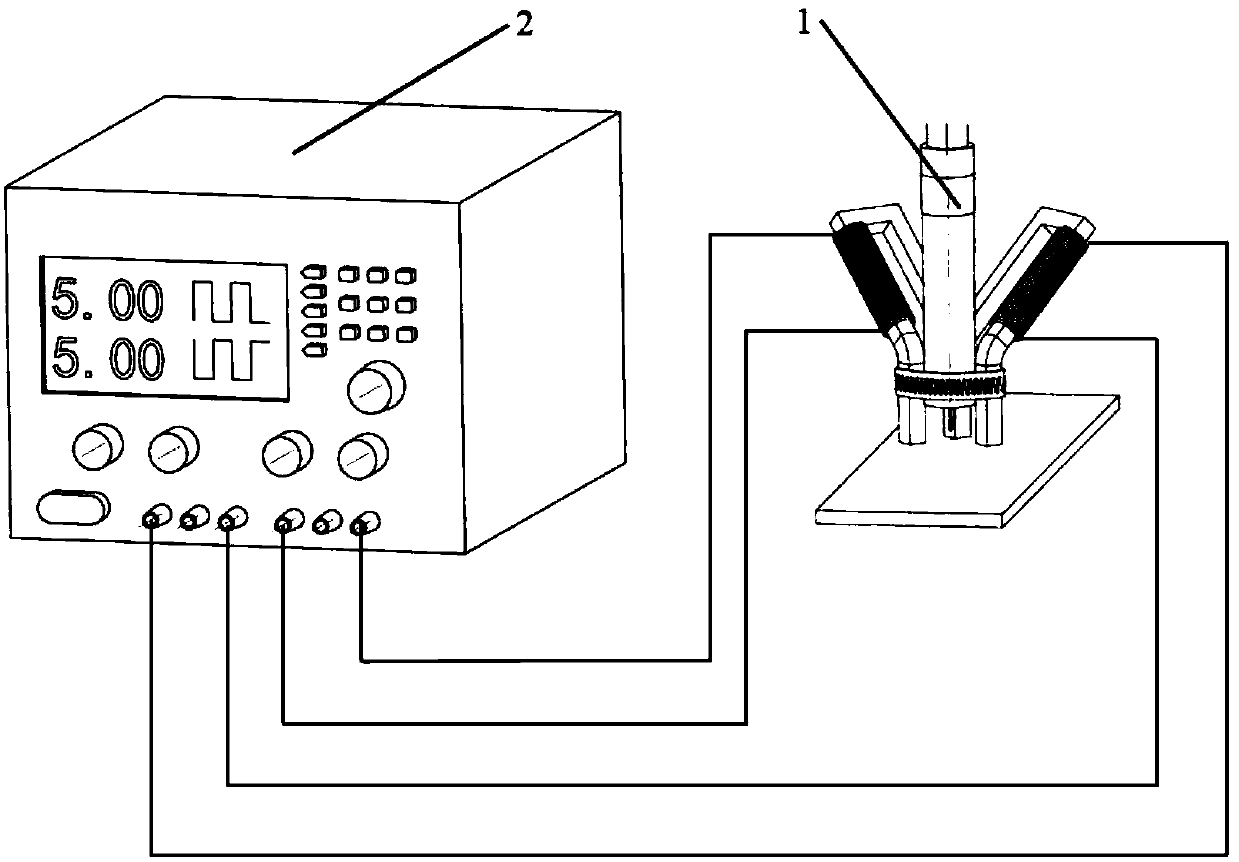

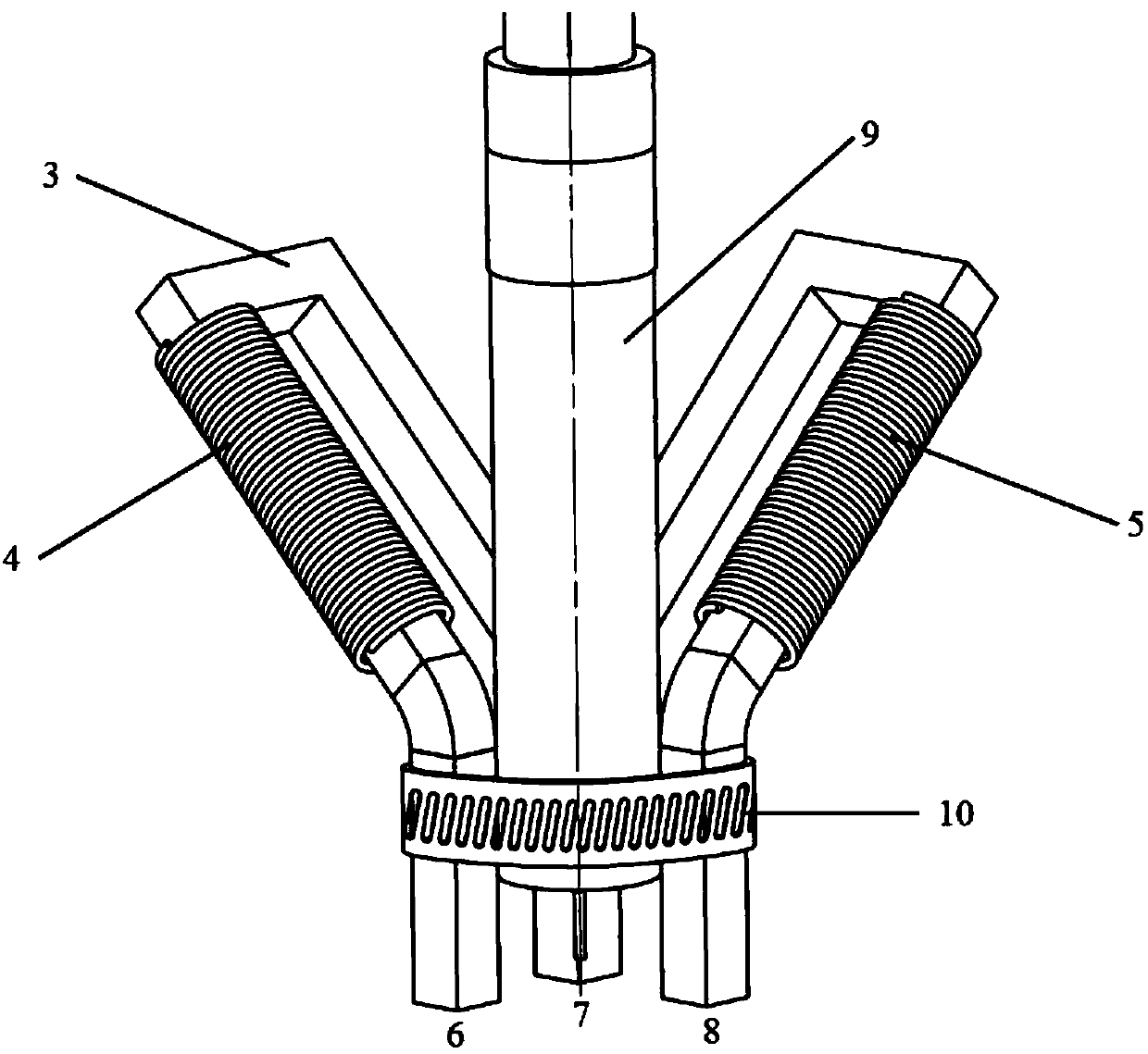

A composite magnetic field and welding device technology, applied in welding equipment, welding accessories, devices for supplying/exhausting protective gas, etc., to achieve the effect of suppressing undercut and hump defects, promoting lateral spreading, and good accessibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

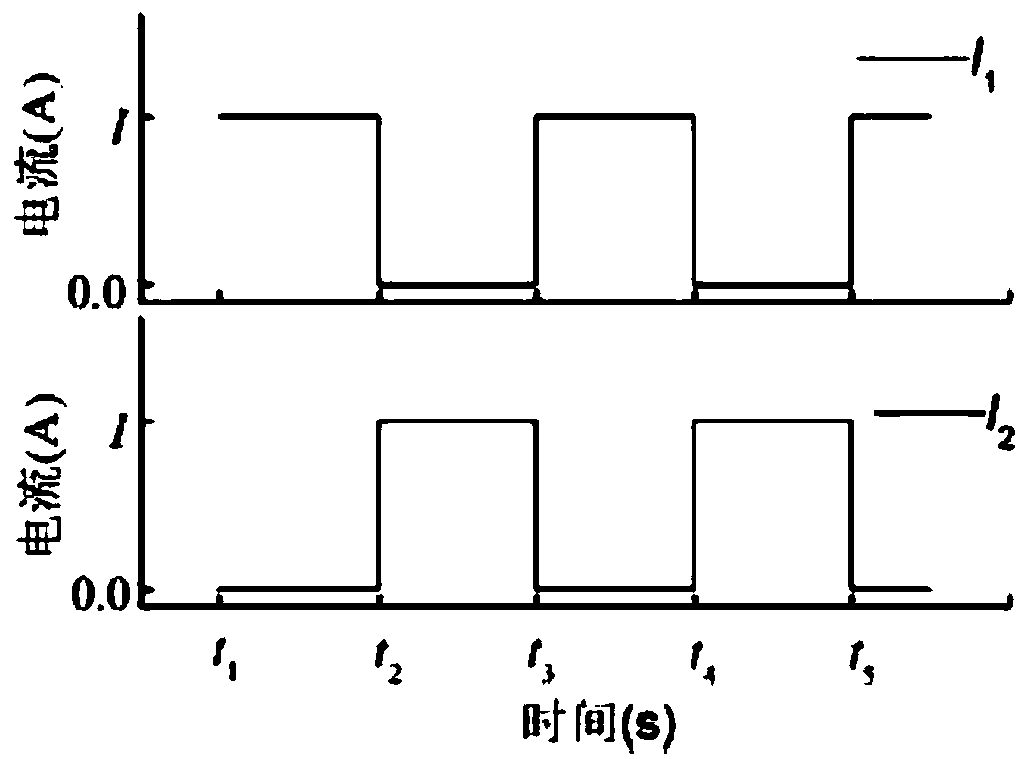

[0051] Embodiment 1: The pulsed composite magnetic field assists the GMAW high-speed welding process. With the device of this embodiment, the generated composite magnetic field is adjusted by adjusting the generated current waveform, and the adjusted external magnetic field is applied to the welding process. The welding workpiece is made of 250×70×5mm Q235 steel plate, the GMAW welding power supply is adjusted, the welding current is 275A, and the welding voltage is 32.5V; the DC pulse adjustable power supply is adjusted to adjust the current waveform to a dual pulse waveform, size 5A, frequency 18Hz, and A current signal with an air ratio of 50% and a phase difference of 180° is welded with an external magnetic field at a welding speed of 1.5m / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com