Additional alternating magnetic field assisted aluminum alloy/steel dissimilar metal melt-brazing method and system

An alternating magnetic field and dissimilar metal technology, applied in metal processing equipment, welding equipment, arc welding equipment, etc., can solve the problems of easy fluctuation of arc energy output, restriction of mechanical properties of joints, poor spreading wettability, etc., to achieve increased brazing Interface area, low cost, effect of reducing wetting angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

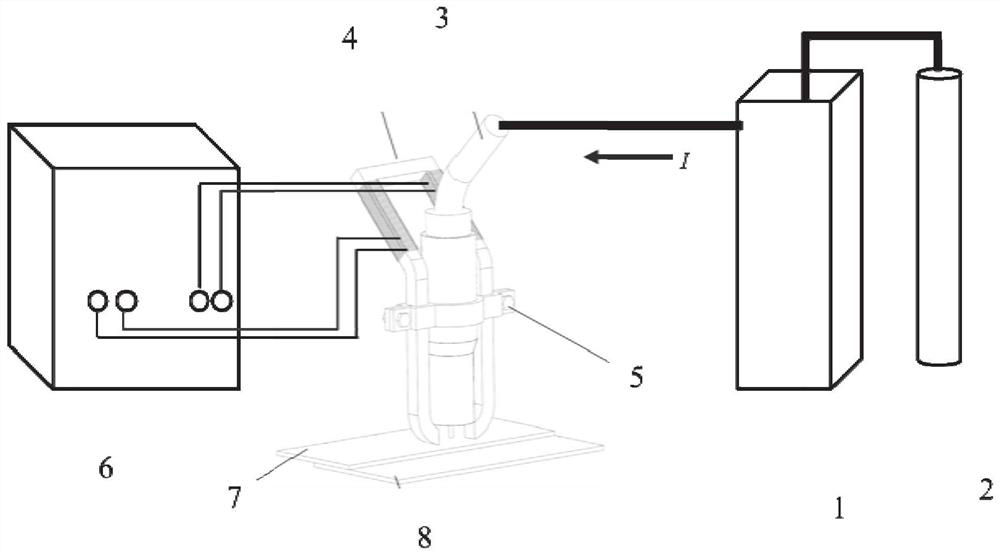

[0043] Aiming at the problems of low joint strength and easy generation of pores during aluminum / steel MIG brazing welding, the invention provides an aluminum / steel MIG brazing welding system assisted by an external alternating magnetic field. figure 1 It is the aluminum / steel MIG brazing system diagram assisted by an external alternating magnetic field of the present invention, including a magnetic generating device 4, a MIG welding machine 1, a dual-circuit excitation power supply 6, and the MIG welding machine 1 is connected to a shielding gas device 2, wherein the shielding gas The gas is pure argon or helium. The magnetic generating device 4 cooperates with the welding torch 3 of the MIG welding machine 1 . The two-way excitation power supply 6 is connected to the coil of the magnetic generator 4 .

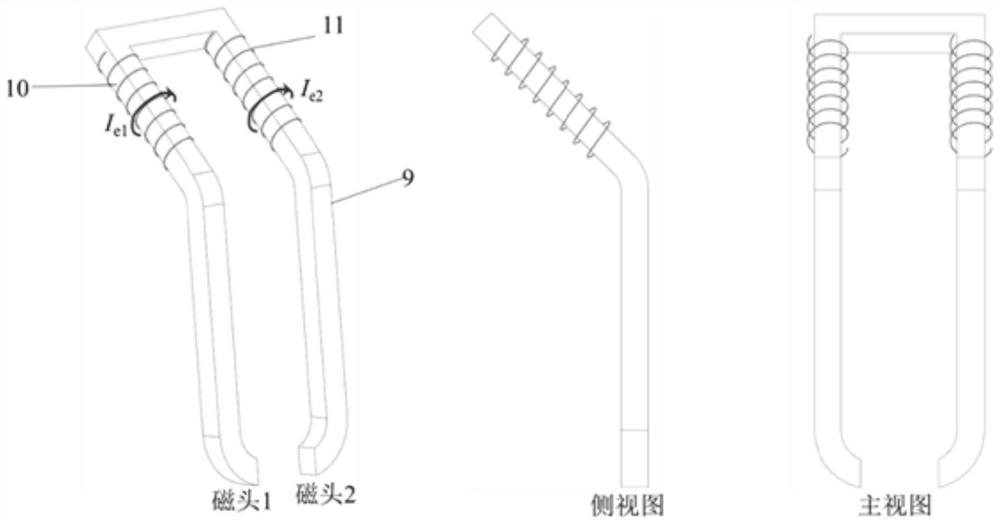

[0044] In one embodiment, as figure 2 As shown, the magnetic generating device 4 includes a U-shaped iron core 9 and two coils wound on the iron core 9, which are respecti...

Embodiment 2

[0049] Step 1. Fix the aluminum alloy plate and steel plate to be welded, wherein the steel plate is on the bottom and the aluminum alloy plate is on top, such as figure 1 shown.

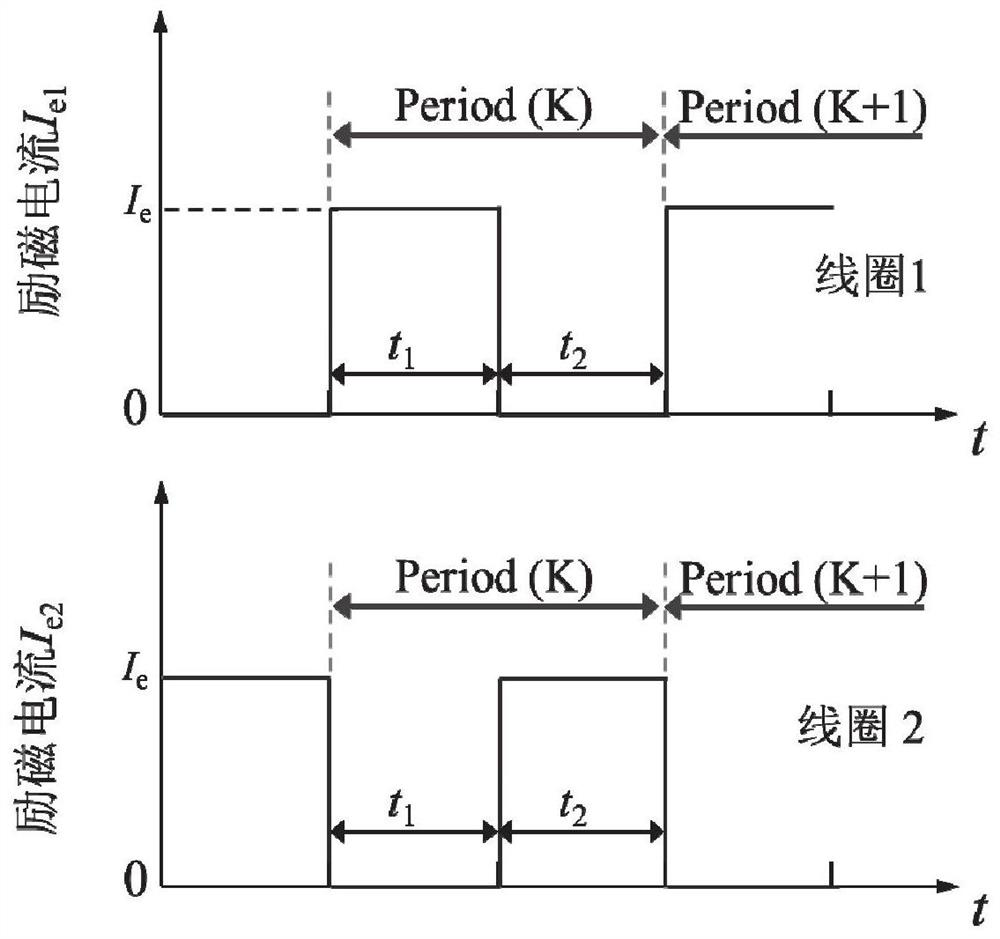

[0050] Step 2: Turn on the excitation power supply and set the excitation parameters. The excitation current waveforms of the two coils are as follows image 3 As shown, the peak value of the excitation current is 2-30A, the base value current is 0, and the pulse frequency is 1-40Hz.

[0051] Step 3. According to the plate thickness and welding speed requirements of the workpiece to be welded, select the appropriate welding process parameters and start welding.

[0052] The aluminum alloy of the welding workpiece is 1mm thick 5052 aluminum alloy plate and 2mm thick low carbon steel galvanized steel plate. Adjust the MIG welding power supply, the welding current is 71A, the wire feeding speed is 3.3m / min, the welding wire is ER4043 wire with a diameter of 1.2mm, the welding speed is 0.6m / min, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com