Novel high-speed electro-deposition efficient round wire welding band equipment

An electrodeposition, high-speed technology, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of non-synchronous operation, low speed, low production, etc., and achieve the effect of good uniformity, improved appearance, and increased operating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the drawings and embodiments.

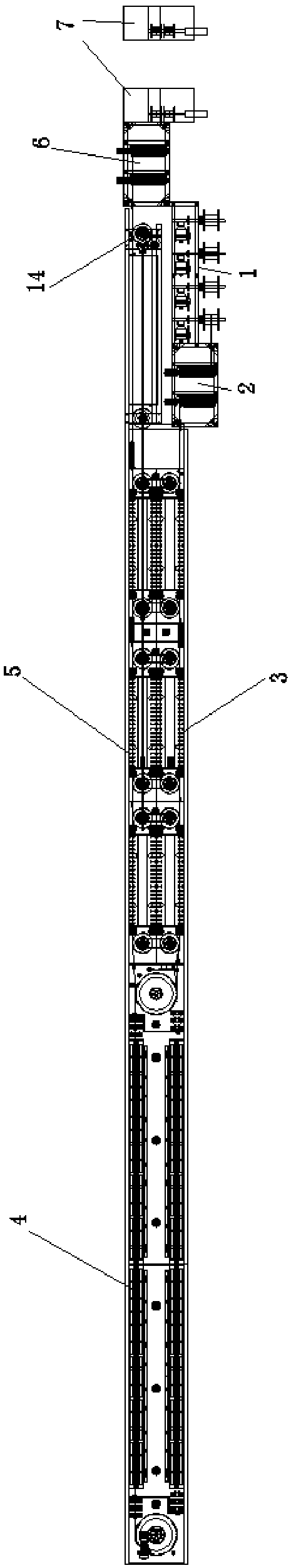

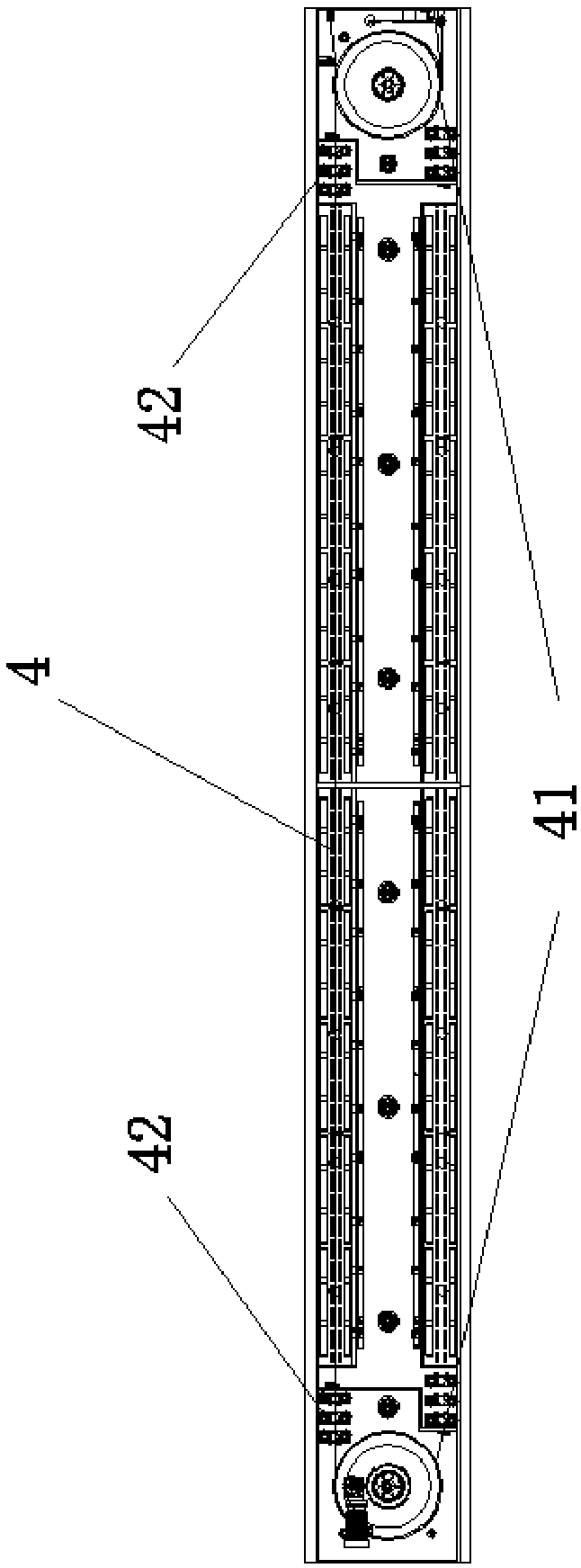

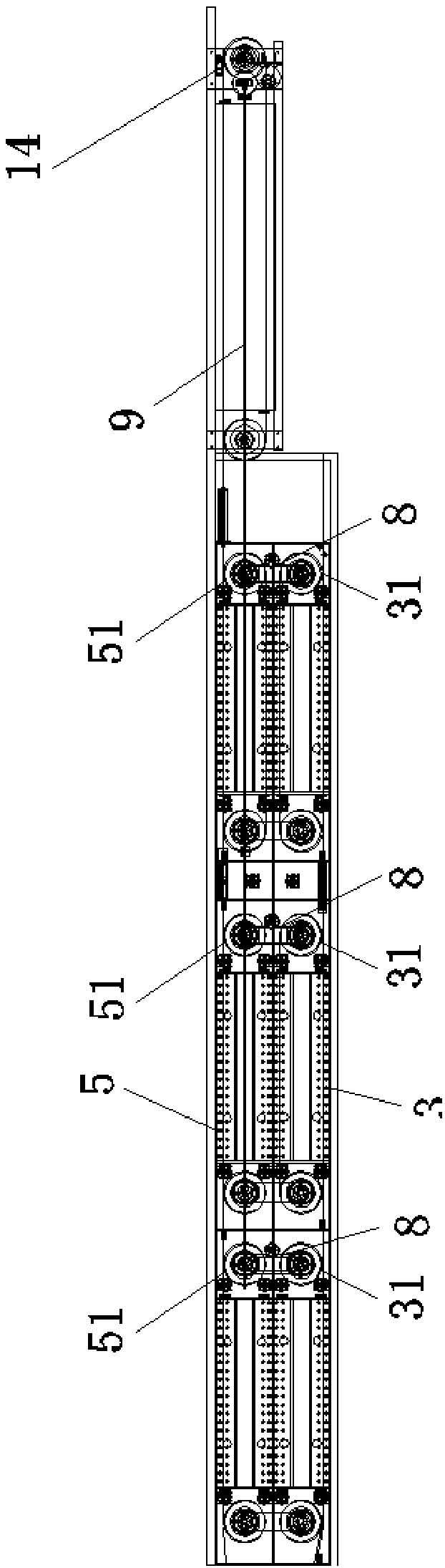

[0016] The present invention is a new type of high-speed electrodeposition high-efficiency round wire welding tape equipment, such as figure 1 As shown, along the operating direction of the equipment, it includes a discharge mechanism 1, a first buffer mechanism 2, a pre-processing mechanism 3, an electroplating mechanism 4, a post-processing mechanism 5, a main drive mechanism 14, a second buffer mechanism 6 and a material receiving mechanism 7. ;Such as image 3 As shown, the pre-processing mechanism 3 includes a pre-processing pulley 31 with equidistant teeth, and the post-processing mechanism 5 includes a post-processing pulley 51 with equi-spacing teeth. The pre-processing pulley 31 and the post-processing pulley 51 are symmetrically arranged, and The two are connected by an endless belt 8 with corresponding teeth on the inner peripheral surface. The post-processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com