Steel-roller high-speed pulp washer

A pulp washer, high-speed technology, applied in the field of papermaking machinery, can solve the problems of inability to meet the production needs of enterprises, short service life of dewatering rollers, and poor pulp dewatering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

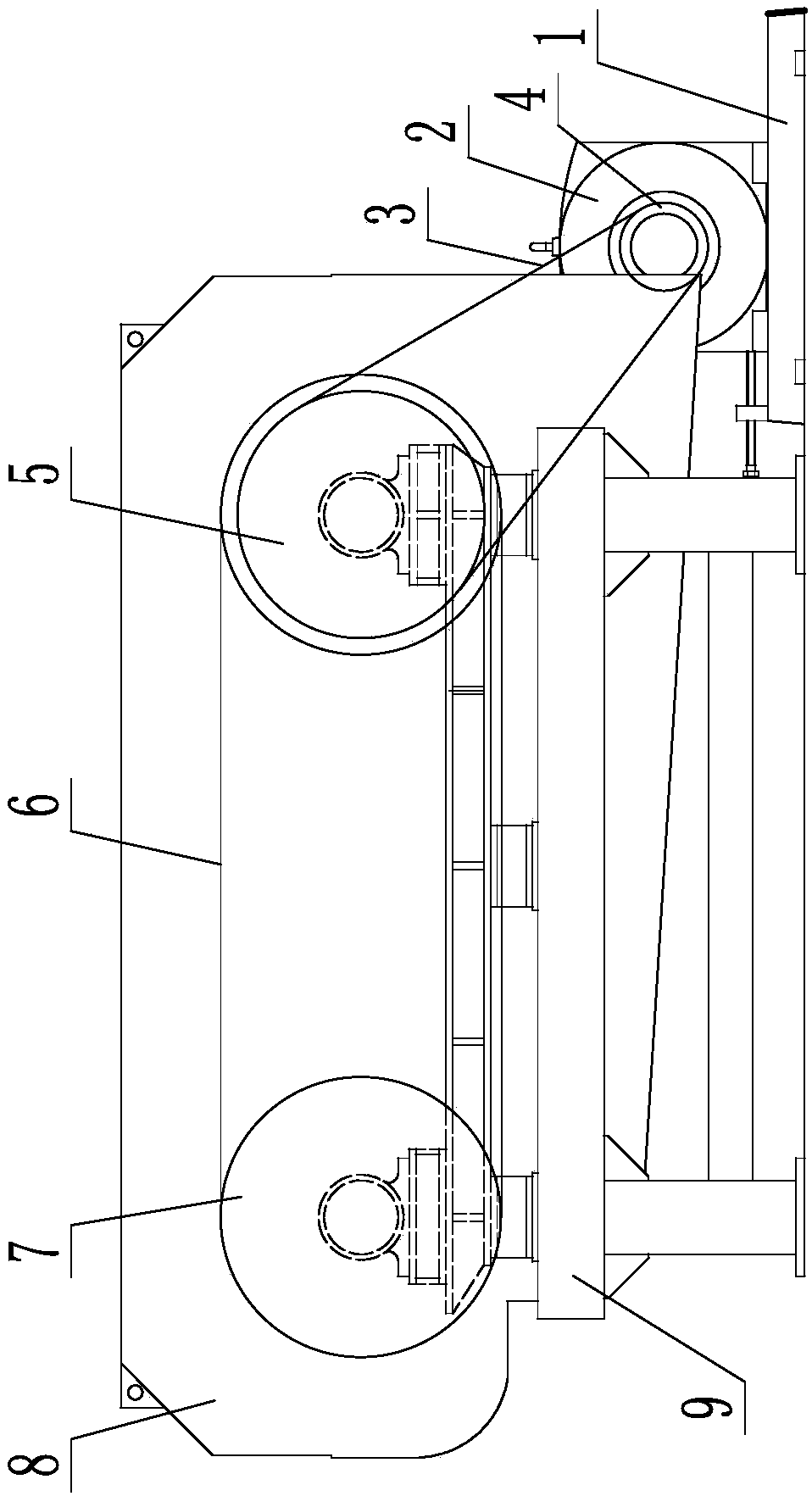

[0011] Such as figure 1 As shown, the present invention comprises base 1, motor 2, belt 3, pulley 4, drive roller 5, is characterized in that, described base 1 top is provided with motor 2, and the pulley 4 of described motor 2 one end passes belt 3 and drive roller 5 connected, the driving roller 5 is arranged on the upper part of the frame body 9 on one side of the base 1, the outer wall of the driving roller 5 is connected with the driven roller 7 through the dehydration net 6, and the driven roller 7 is arranged on the frame body 9 upper side.

[0012] The driven roller 5 is a grooved roller whose roller surface is made of steel.

[0013] The upper part of the frame body 9 is also provided with a protective shell 8 covering the driving roller 5 and the driven roller 7 .

[0014] Through the above settings, the present invention drives the belt pulley 4 and the driving roller 5 to rotate through the motor 2, and the driving roller 5 rotates at a high speed through the dew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com