Fast-assembled-disassembled tooth-embedding-type unstressed fixed ball supporting base

A tooth-embedded, stress-free technology, applied to bridge parts, bridges, buildings, etc., can solve the problems of uneven force, large outer edge size of the upper support, and shorten the service life of the support, so as to reduce the cost of the support , Small structure size, large moment bearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

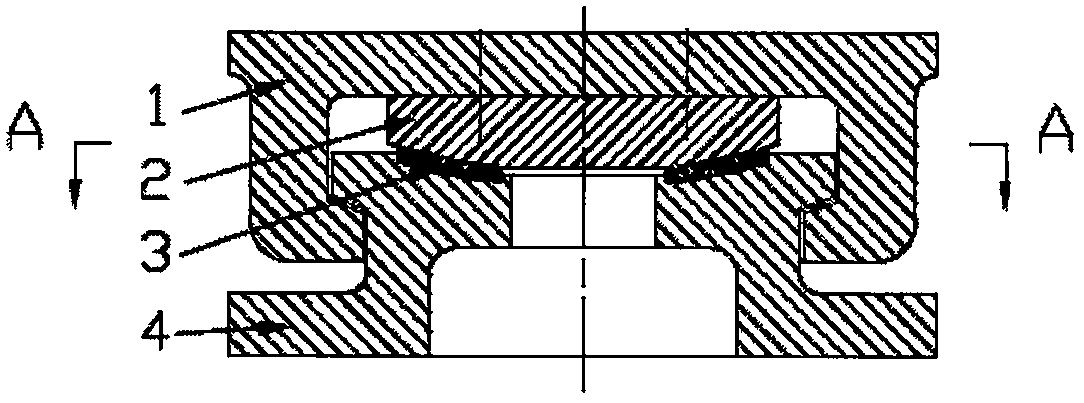

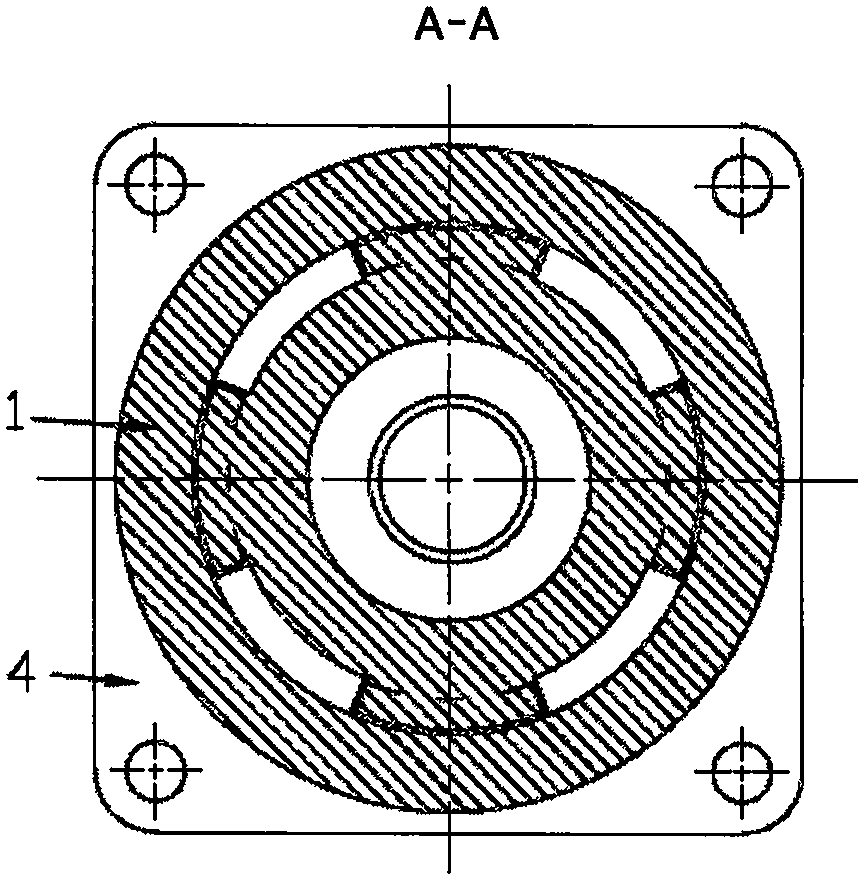

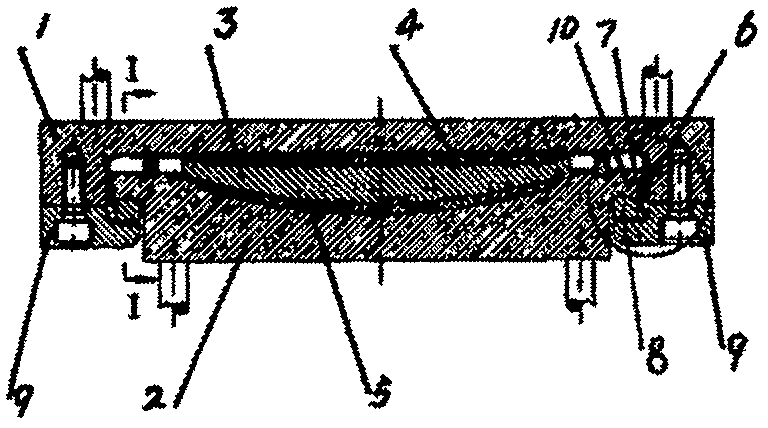

[0030] A fast loading and unloading tooth-embedded stress-free fixed ball bearing includes an upper bearing 1, a spherical crown-shaped liner 2, a spherical tetrafluoro sliding ring 3, and a lower bearing 4.

[0031] The upper support 1 has four zigzag inner teeth and the lower support 4 with four zigzag outer teeth together form a tensile, shear and torsion device; a spherical crown-shaped liner connected with the upper support 1 2 and the spherical tetrafluoro sliding ring 3 inlaid on the lower support 4 form an anti-vibration and relief or stress relief device.

[0032] The support effectively solves the stress concentration problem of the straddle-type monorail track beam bearing under the combined force conditions of tension, shear, and torsion, and protects the straddle-type monorail track beam. At the same time, the support structure More compact, safe and reliable.

[0033] In the present invention, the upper support 1 and the spherical liner 2 are bolted together to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com