Rapid Treatment Method for Grout Leakage of Large Diameter Pile Foundation

A treatment method and large-diameter technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as unsatisfactory results, achieve high construction efficiency, obvious effects, and ensure construction progress and project quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

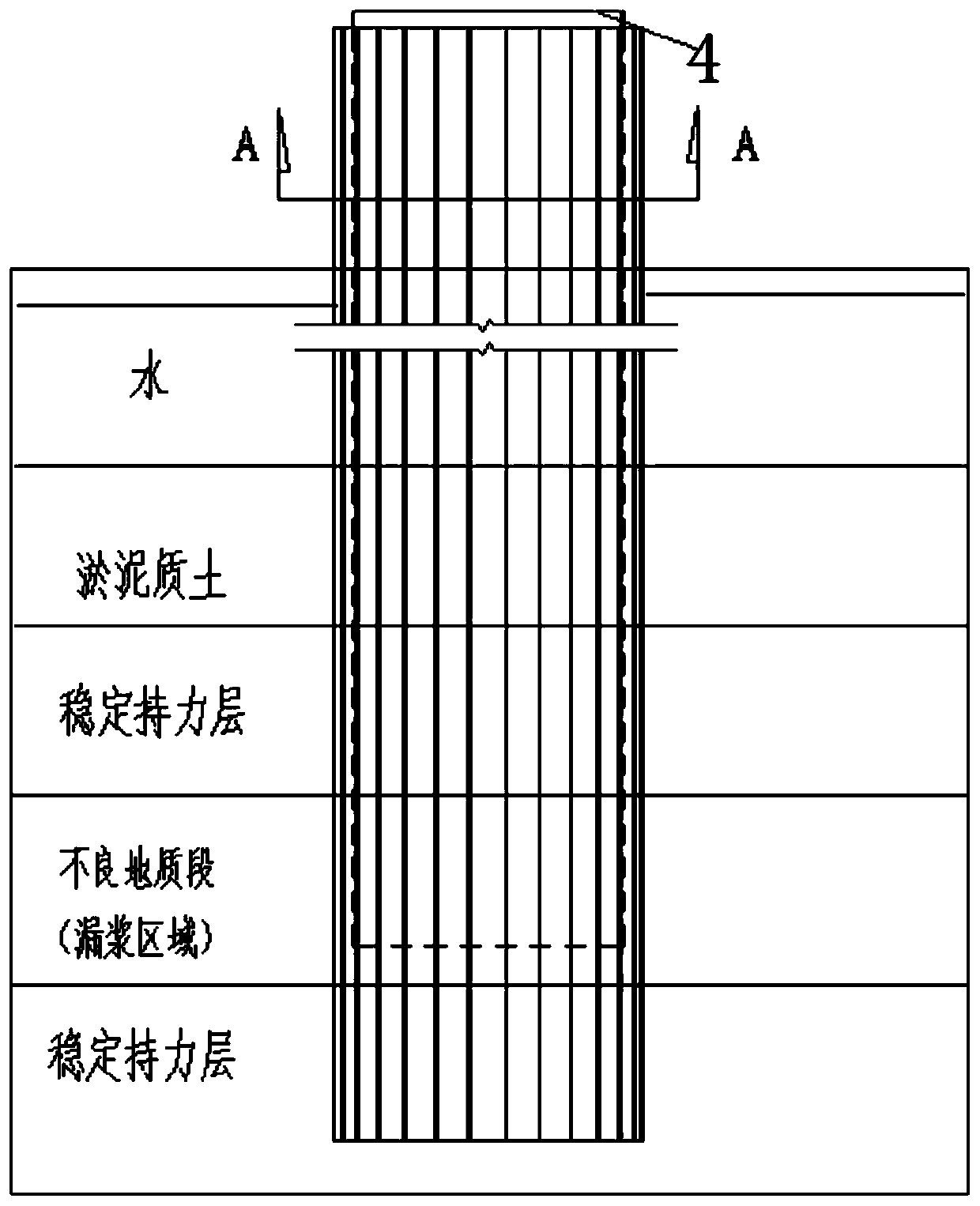

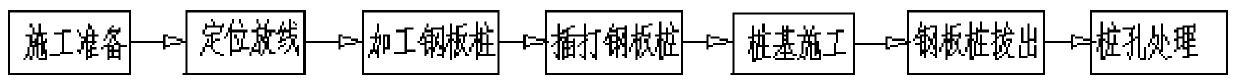

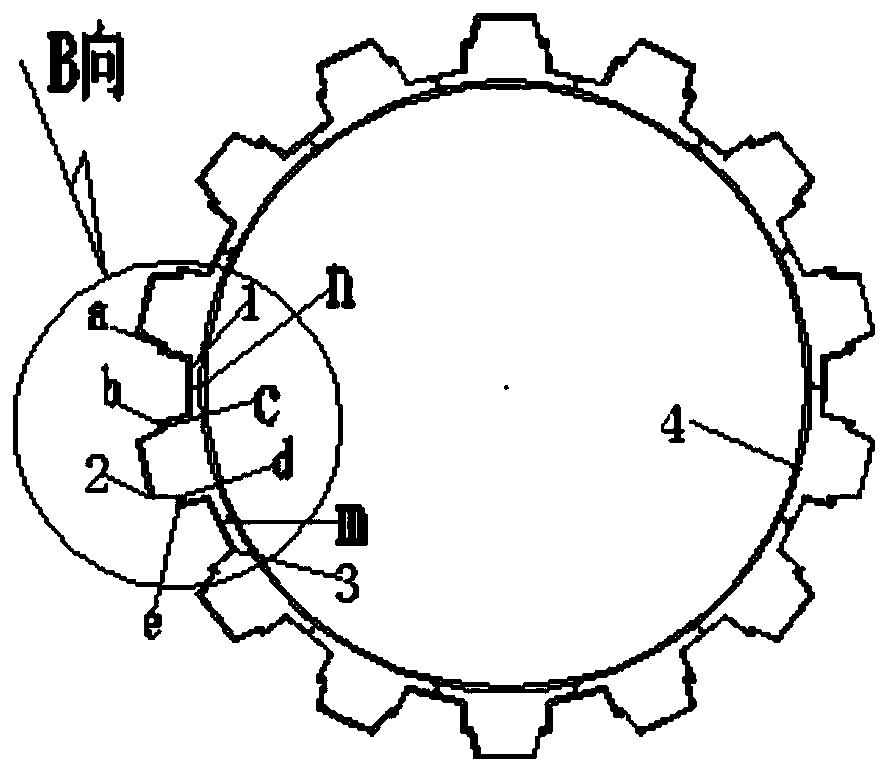

[0025] given in the present invention figure 1 , figure 2 , image 3 and Figure 4 In the embodiment, a rapid treatment method for large-diameter pile foundation grout leakage, by inserting the first stiffened steel sheet pile 1 and the second stiffened steel sheet pile 3 with the same structure at equal intervals on the periphery of the steel casing, and then inserting the second stiffened steel sheet pile The steel sheet pile 2 is inserted between the first stiffened steel sheet pile 1 and the second stiffened steel sheet pile 3 at equal intervals to form a protective pile around the steel casing; the first stiffened steel sheet pile 1, the second stiffened steel sheet pile 3 and the steel sheet pile Insert and sink along the periphery of the steel casing, so that the bottom of the protective steel sheet pile passes through the slurry leakage area to reach the stable bearing layer, forming a small cofferdam protection circle, blocking the path of slurry leakage, and ensur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com