Plastering device for connecting position of wall body and ceiling

A technology for connecting parts and ceilings, which is applied to buildings and building structures, etc., can solve the problems of increased time cost, easy damage to the coating surface, low efficiency, etc., and achieve the effect of improving work efficiency and increasing time cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

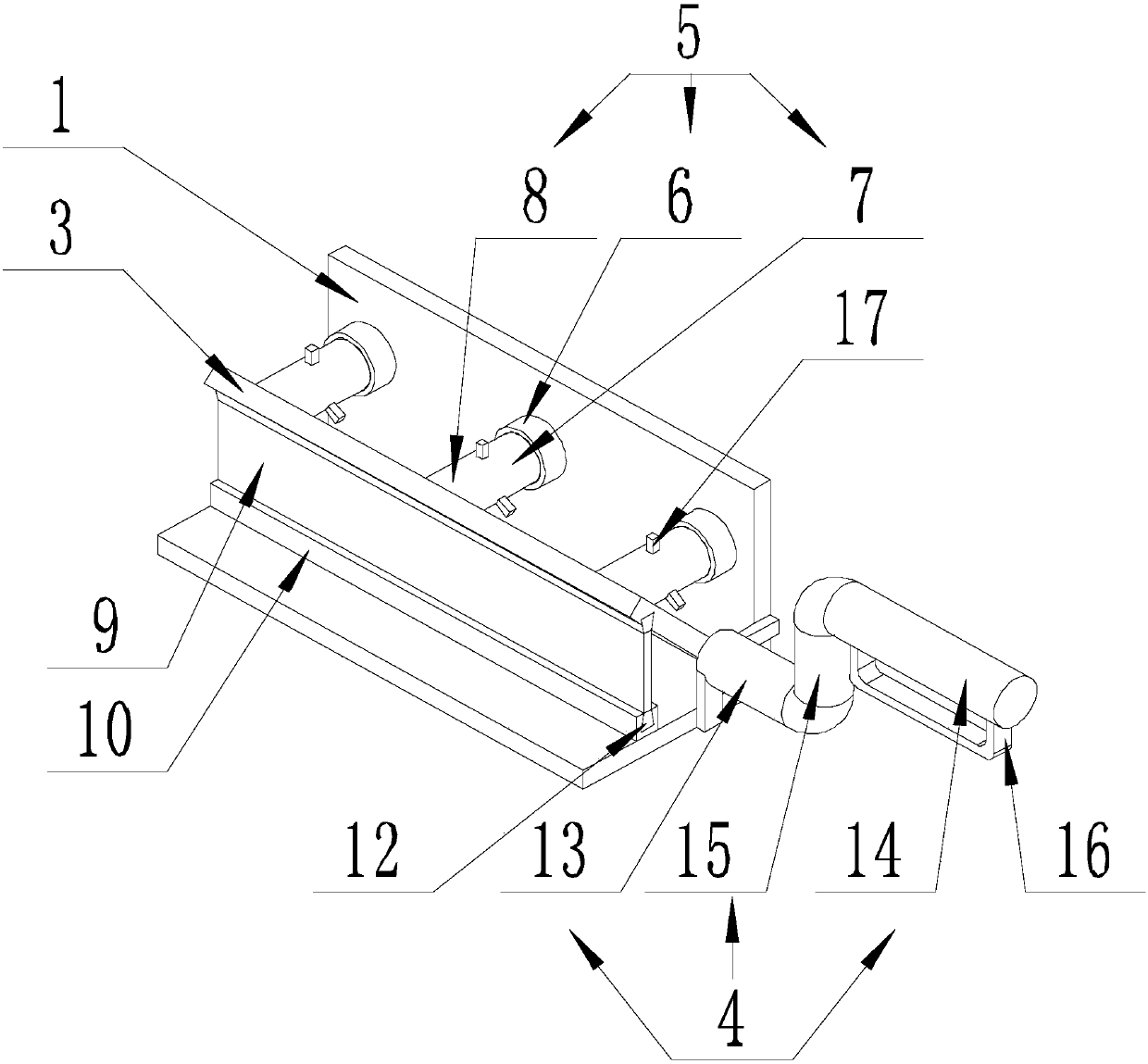

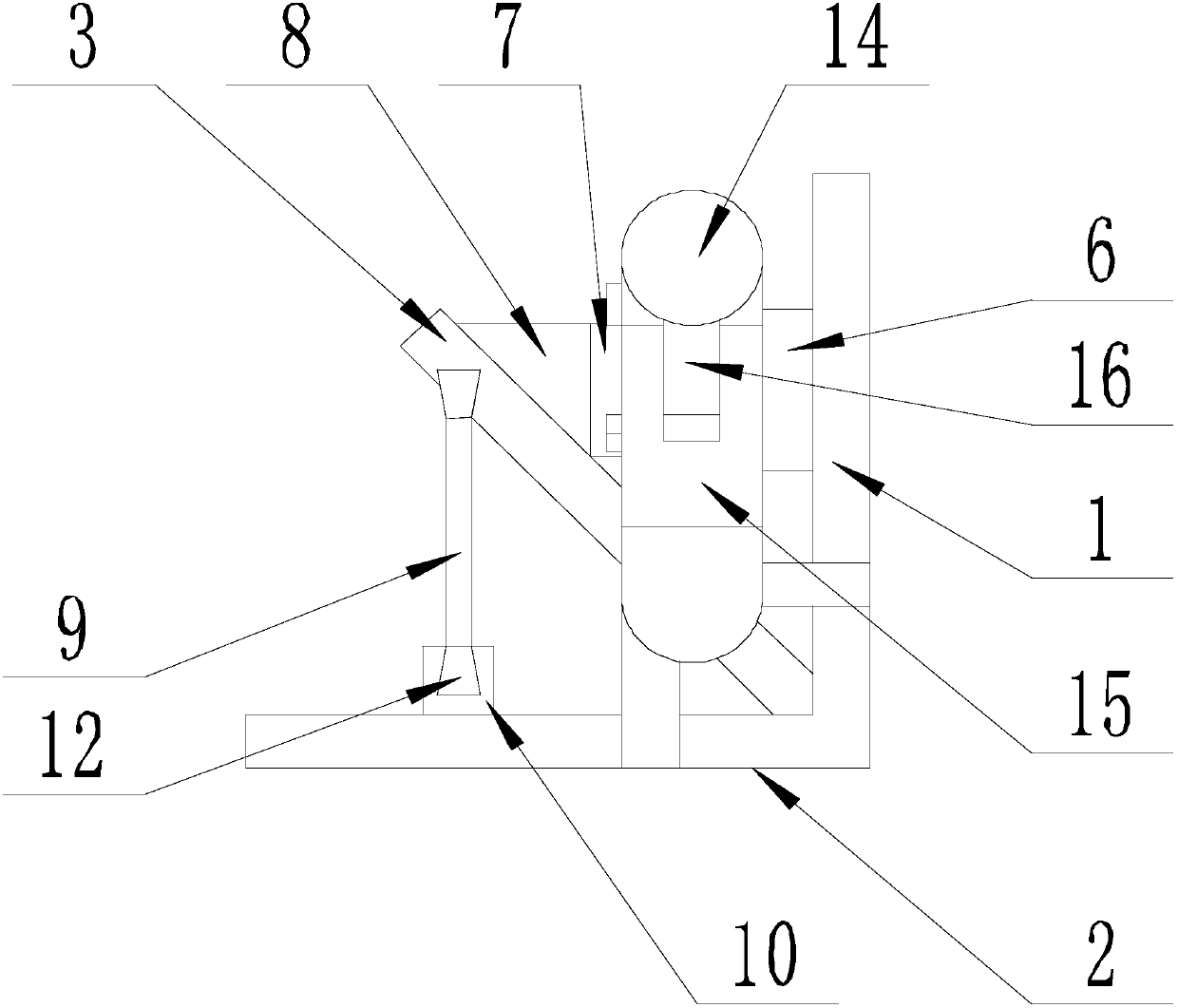

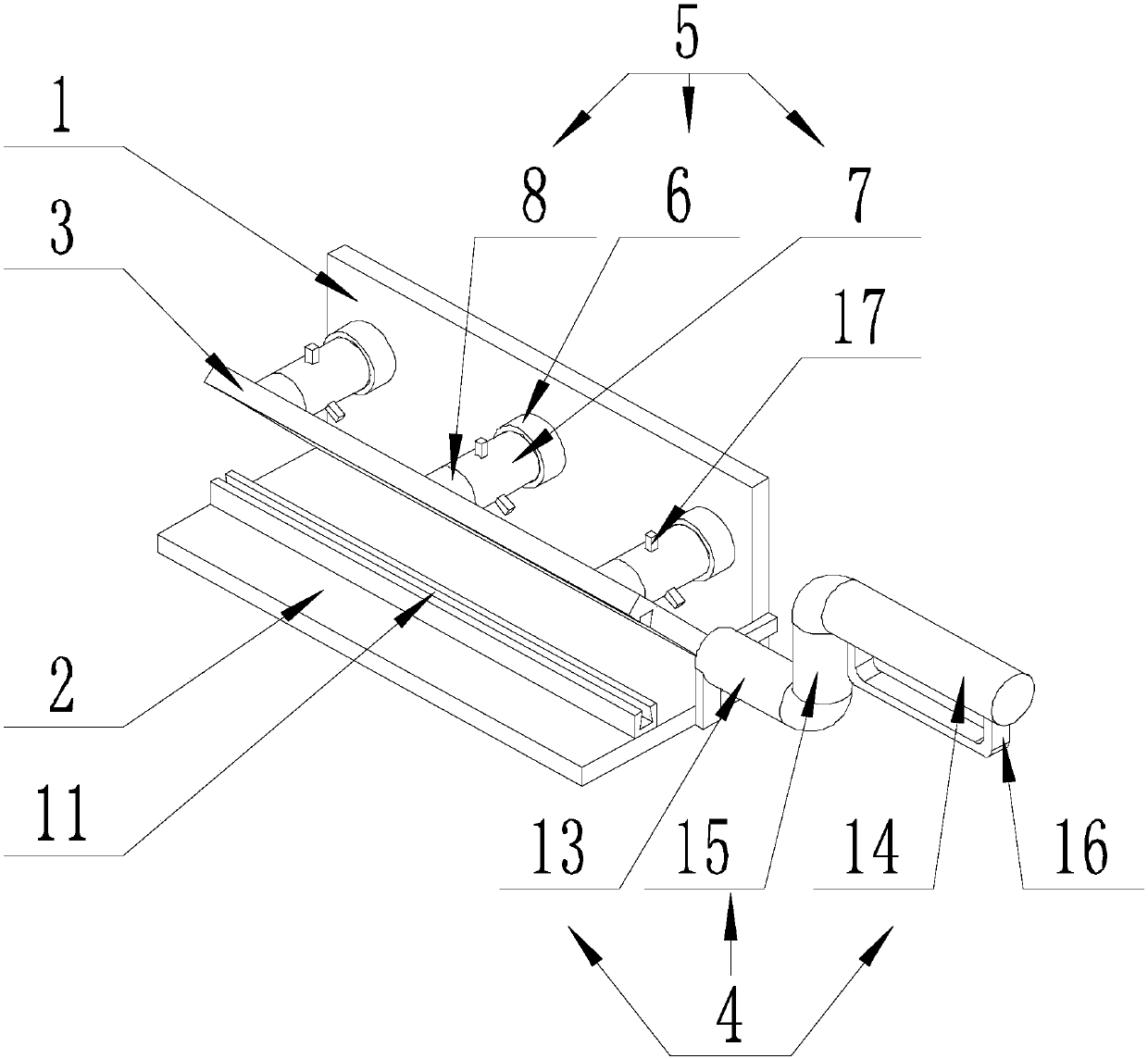

[0040] Such as Figure 1-Figure 5 As shown, the plastering device for the connection between the wall and the ceiling of the present invention includes a wiper I1 and a wiper II2, one side of the wiper I1 is connected to a side of the wiper II2, and the wiper I1 and the wiper The plates II2 are perpendicular to each other. On the opposite surfaces of the wiper I1 and the wiper II2, there are sequentially connected support plates 3 and handles 4. One side of the support plate 3 is connected to the wiper I1 and the wiper II2. The parts are connected, and the support plate 3 is parallel to the connection edge line between the wiper I1 and the wiper II2, and equally divides the right angle formed between the wiper I1 and the wiper II2;

[0041] One end of the handle 4 is connected to one end of the support plate 3, and the other end of the handle 4 extends away from the support plate 3;

[0042] Several telescopic rods 5 are arranged between the wiper I1 and the support plate 3, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com