Manufacturing method of supporting mechanism of curved surface liquid crystal display device

A technology for a liquid crystal display device and a supporting mechanism, which is applied to supporting machines, mechanical equipment, machines/stands, etc., can solve problems such as limited visual experience, and achieve the effect of long service life and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

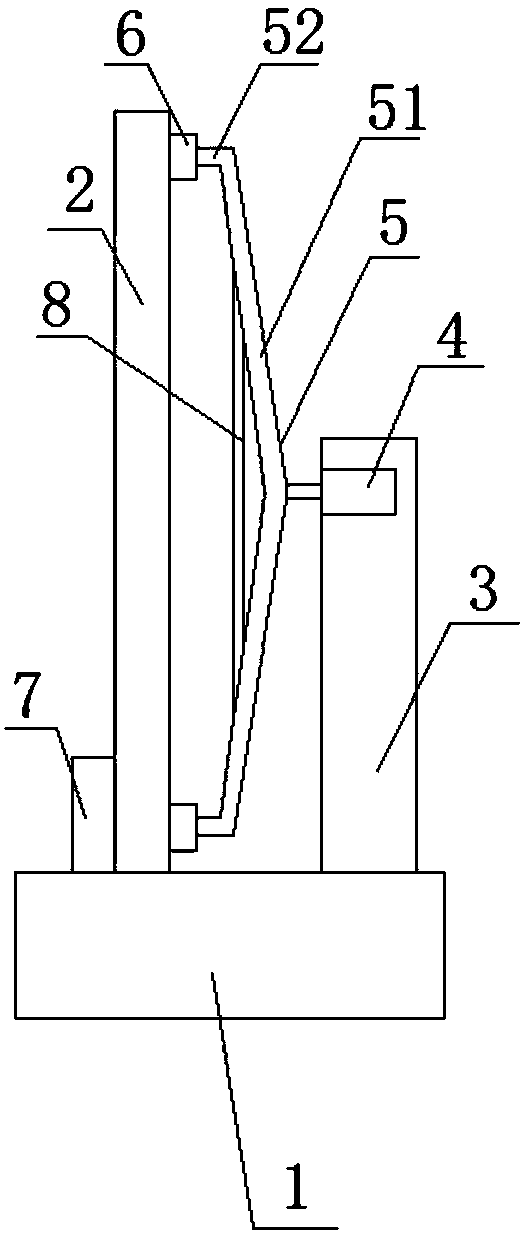

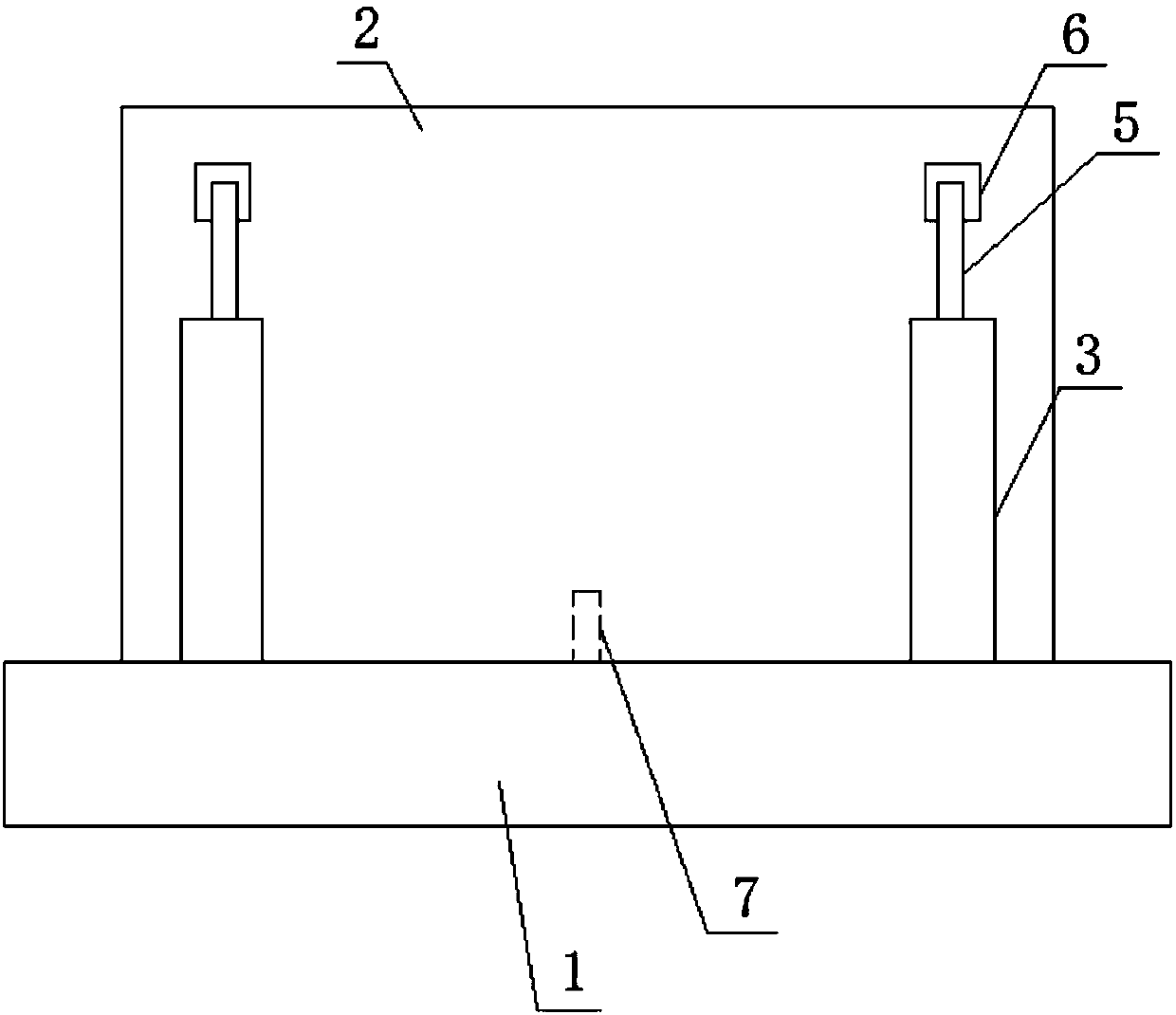

[0032] see Figure 1 to Figure 2 , the present invention provides a curved liquid crystal display device, comprising: a bottom plate 1, a display screen 2, a cylinder fixing seat 3, a telescopic cylinder 4, a support rod 5, a connecting block 6 and a blocking column 7; the blocking column 7 and the cylinder The fixed seats 3 are all arranged on the base plate 1; the number of the cylinder fixed seats 3 is two, and the cylinder fixed seats 3 are arranged on one side of the retaining column 7, and the two cylinder fixed seats 3 are opposite to each other. Symmetrical to the blocking column 7; the display screen 2 is arranged on the bottom plate 1, and is located between the blocking column 7 and the cylinder fixing seat 3; the front bottom of the display screen 2 and the blocking column 7; the telescopic cylinder 4 is arranged on the side of the cylinder fixing seat 3 facing the back of the display screen 2; the support rod 5 includes a first support part 51 and a The second su...

Embodiment 2

[0037] A method for manufacturing a support mechanism of a curved liquid crystal display device, the steps are as follows:

[0038] 1), structure and separate processing

[0039] The support mechanism includes a display screen, a cylinder fixing seat placed on one side of the display screen, and a support rod. The telescopic cylinder is arranged on the side of the cylinder fixing seat facing the back of the display screen; the support rod includes a first support part and a support rod connected to the first support part The second support part; the first support part is herringbone, and one end of the first support part is connected with the telescopic rod of the telescopic cylinder; the upper and lower ends of the first support part are provided with a second support part, and the end of the second support part is provided with There is a connection block, and the connection block is connected with the back of the display screen;

[0040] The telescopic cylinder is prepared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com