Patents

Literature

32results about How to "Curvature adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

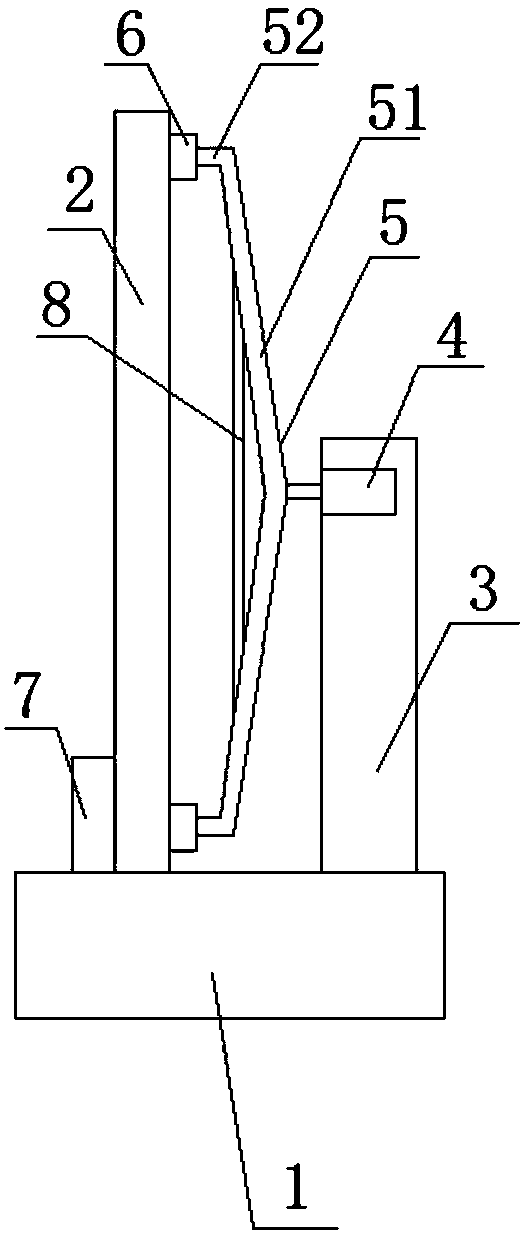

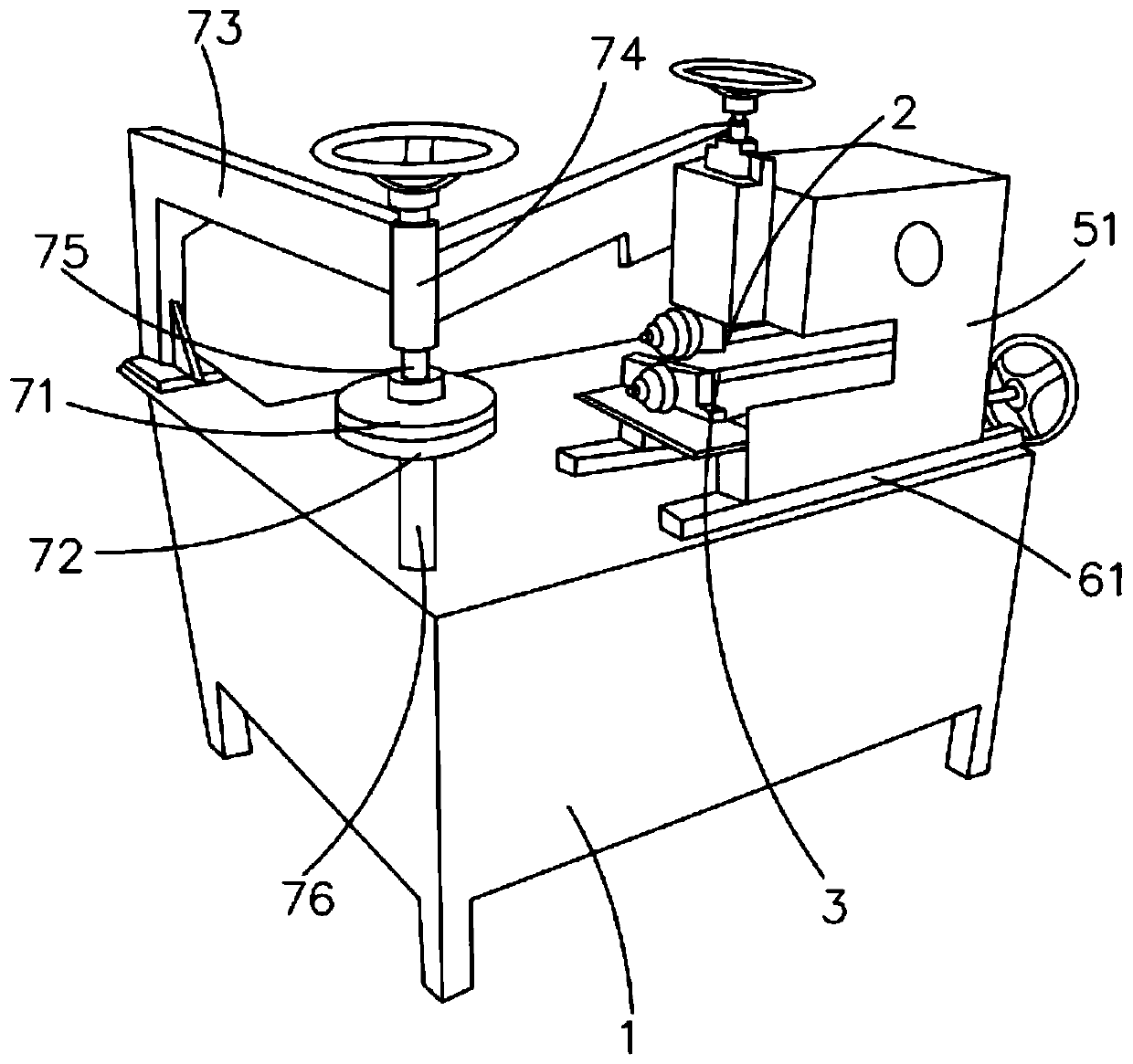

Curvature adjustment structure for curved-surface liquid crystal displayer

ActiveCN103941456ACurvature adjustmentCurvature is easily adjustableNon-linear opticsLiquid-crystal displayEngineering

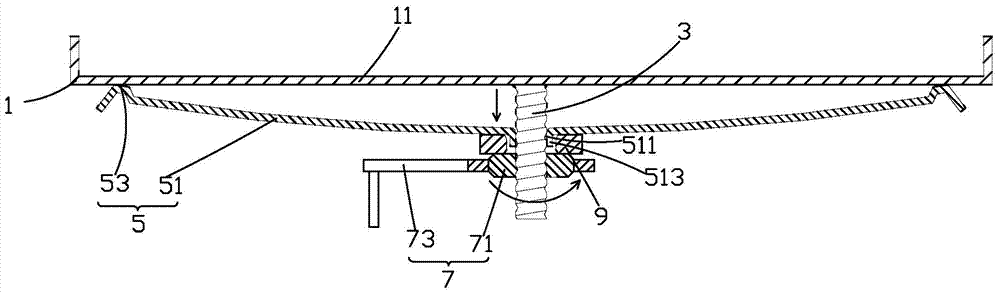

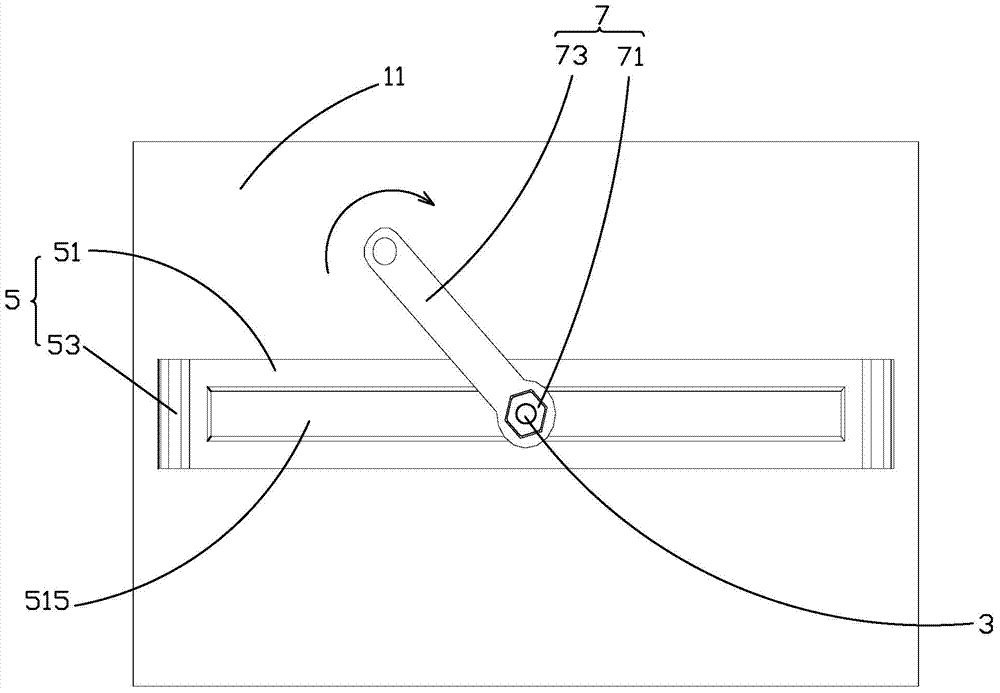

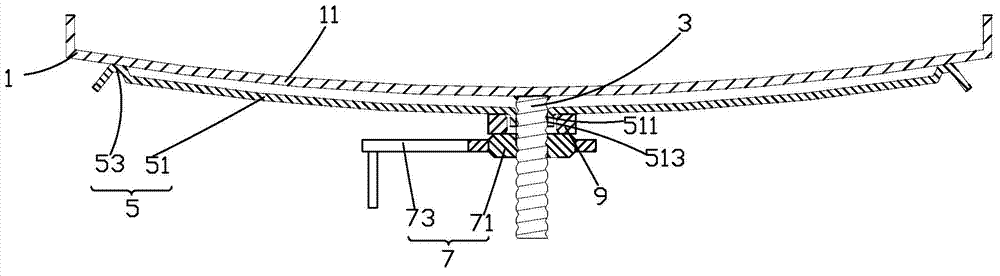

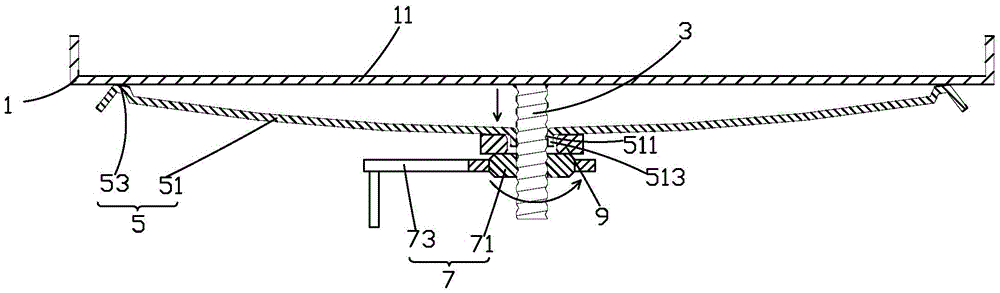

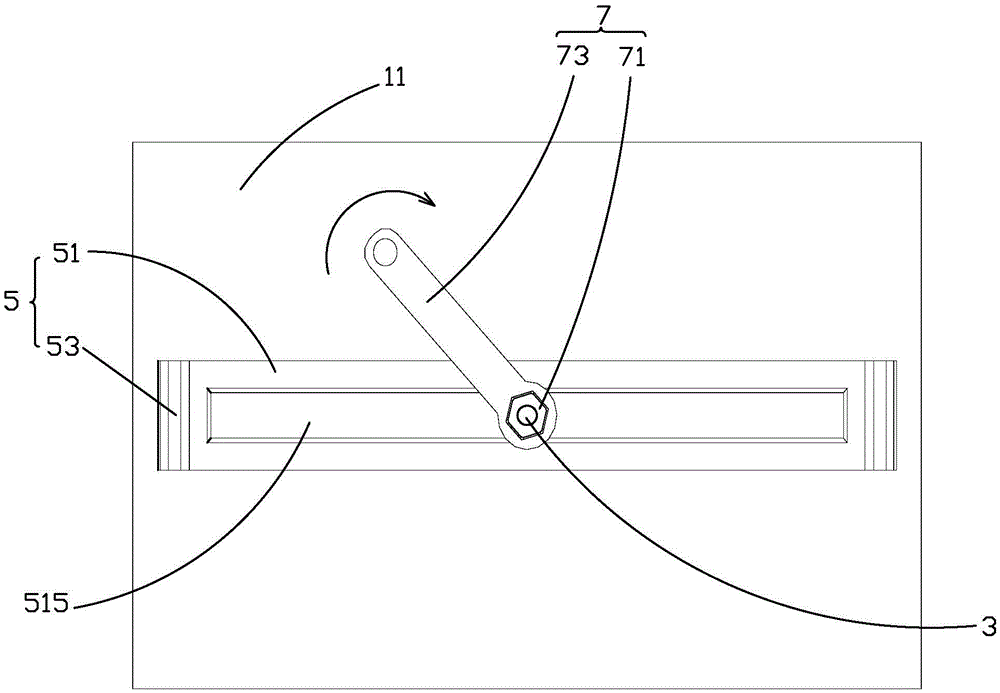

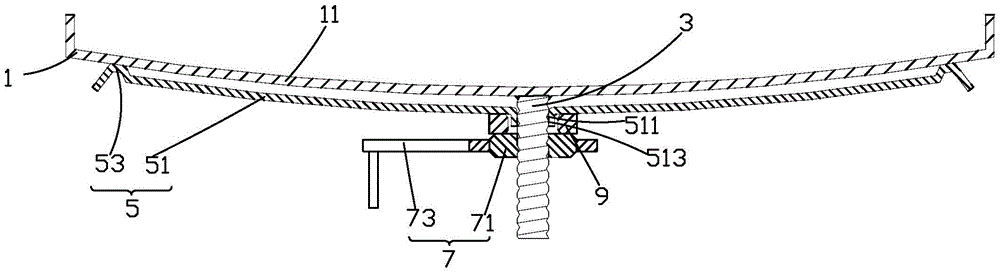

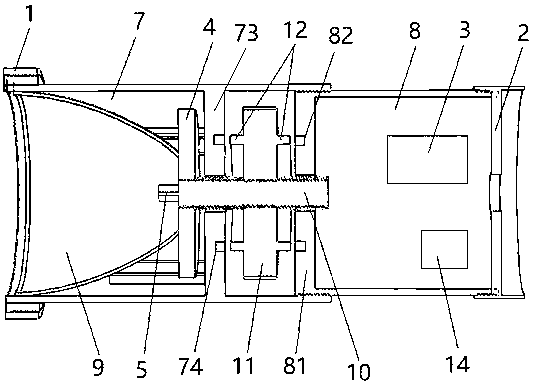

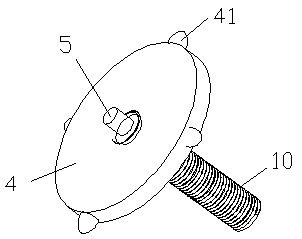

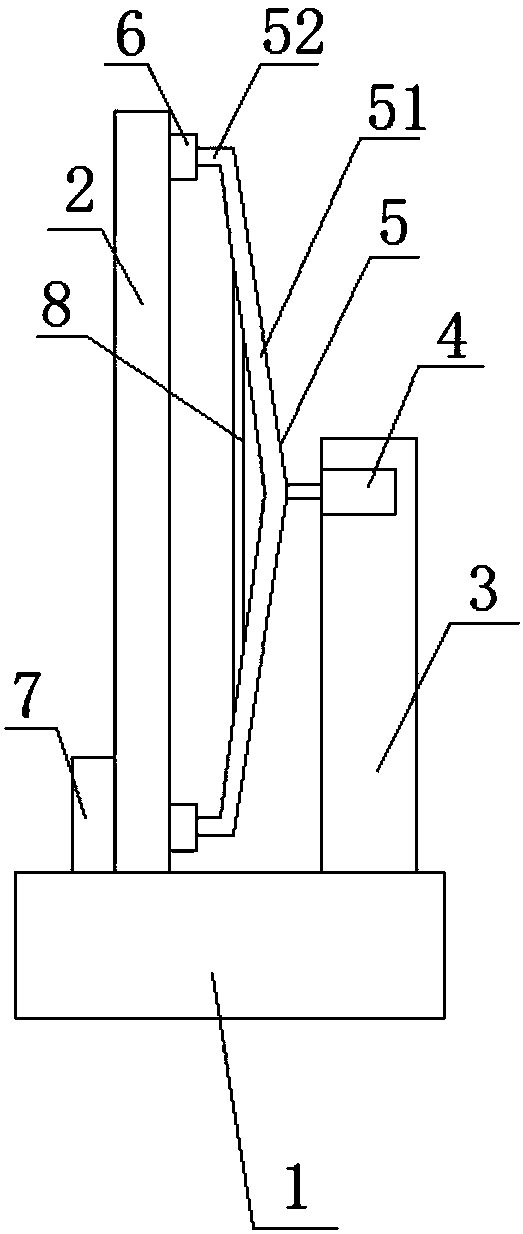

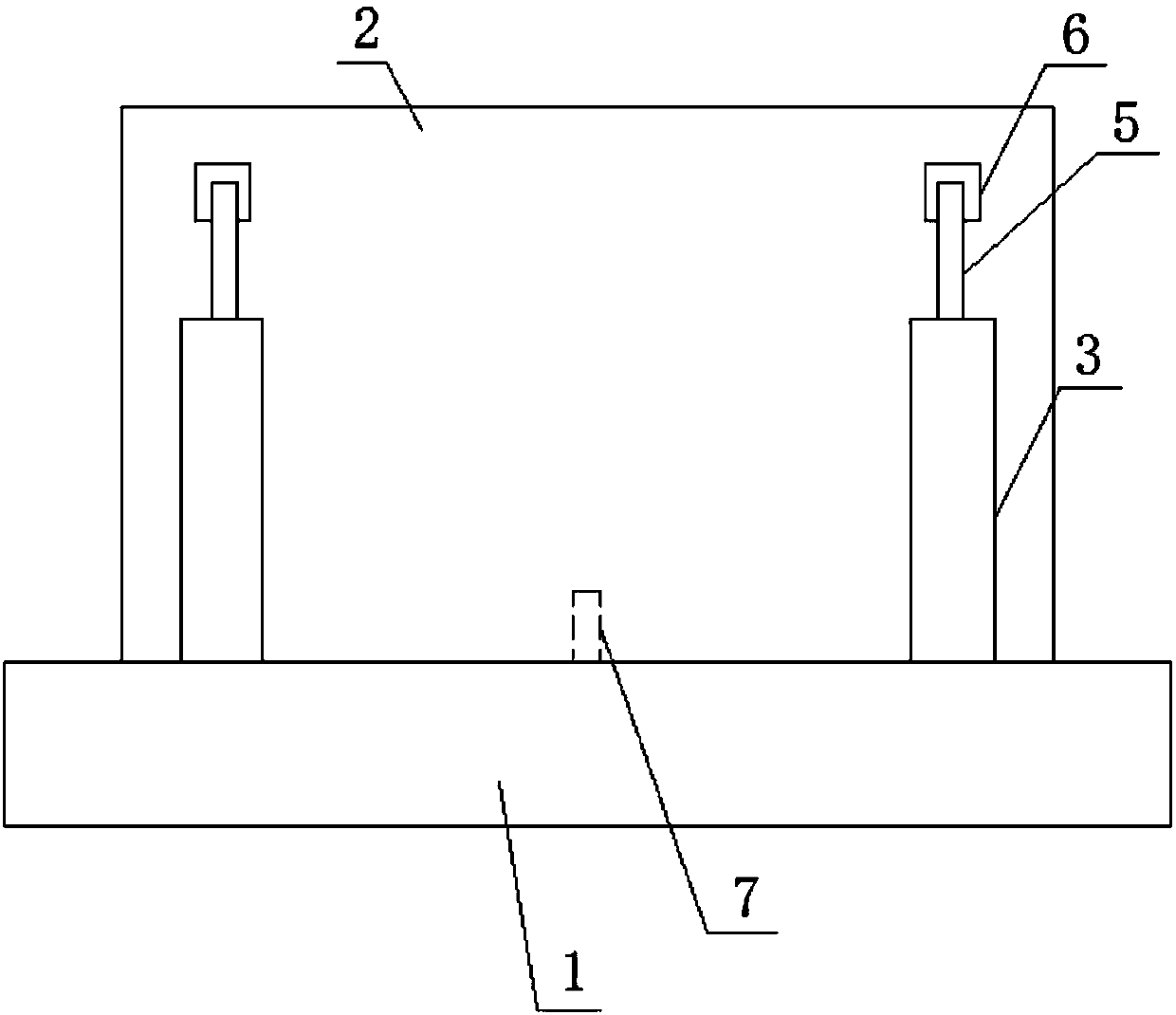

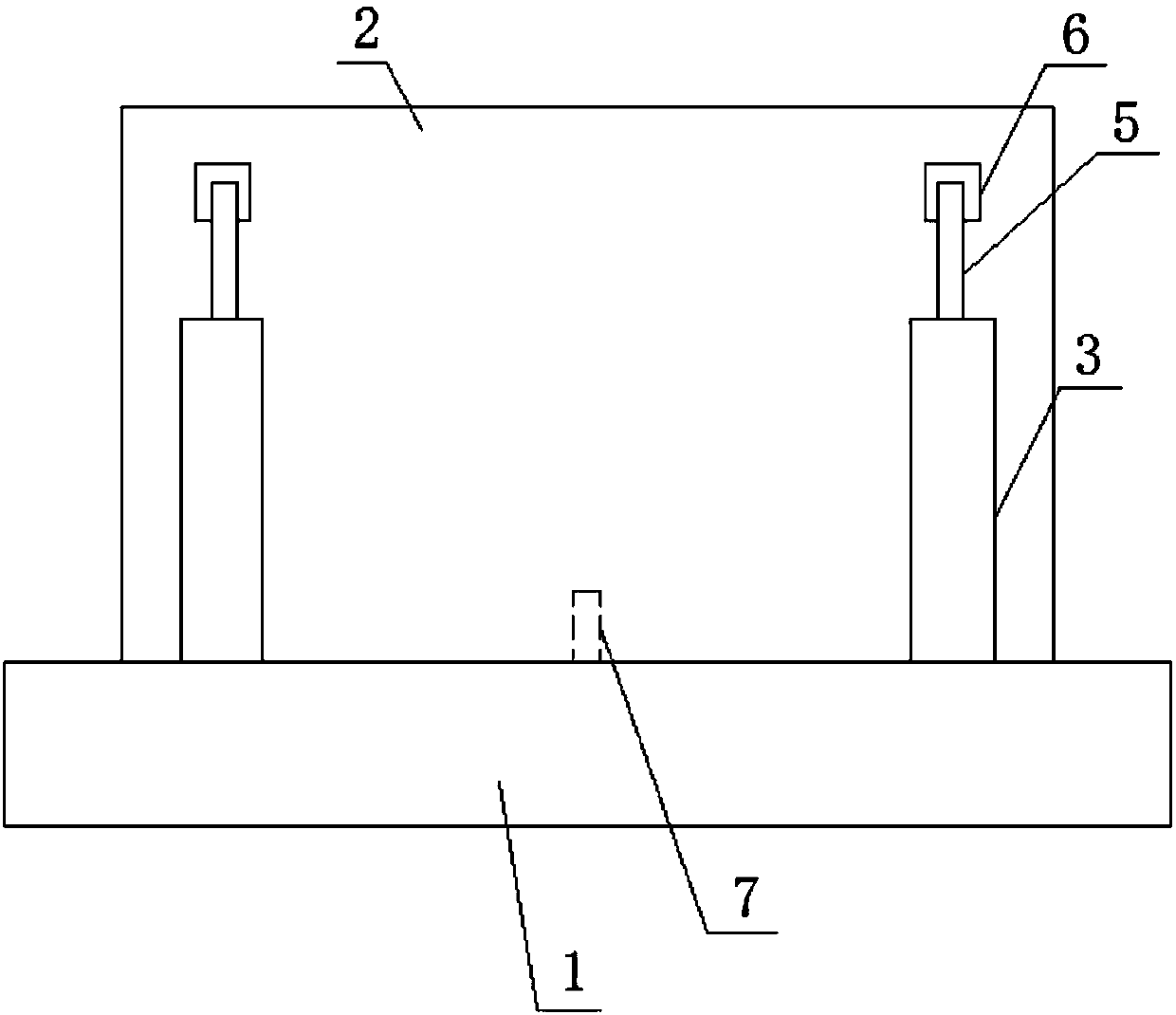

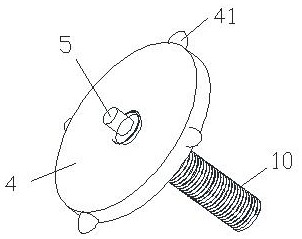

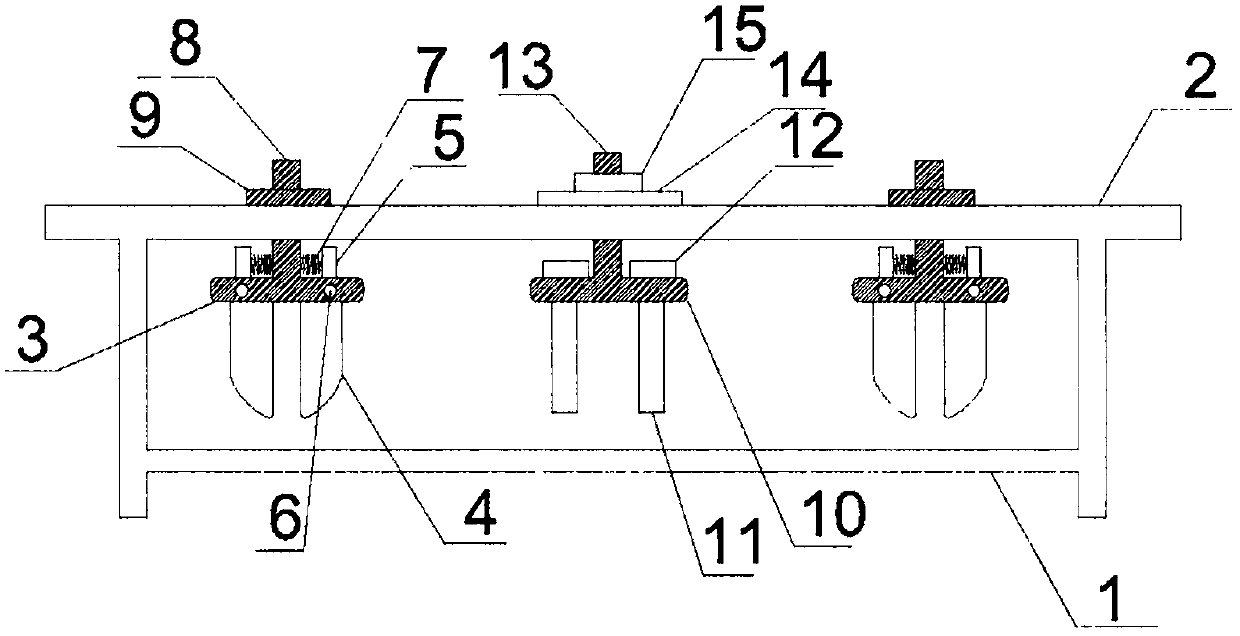

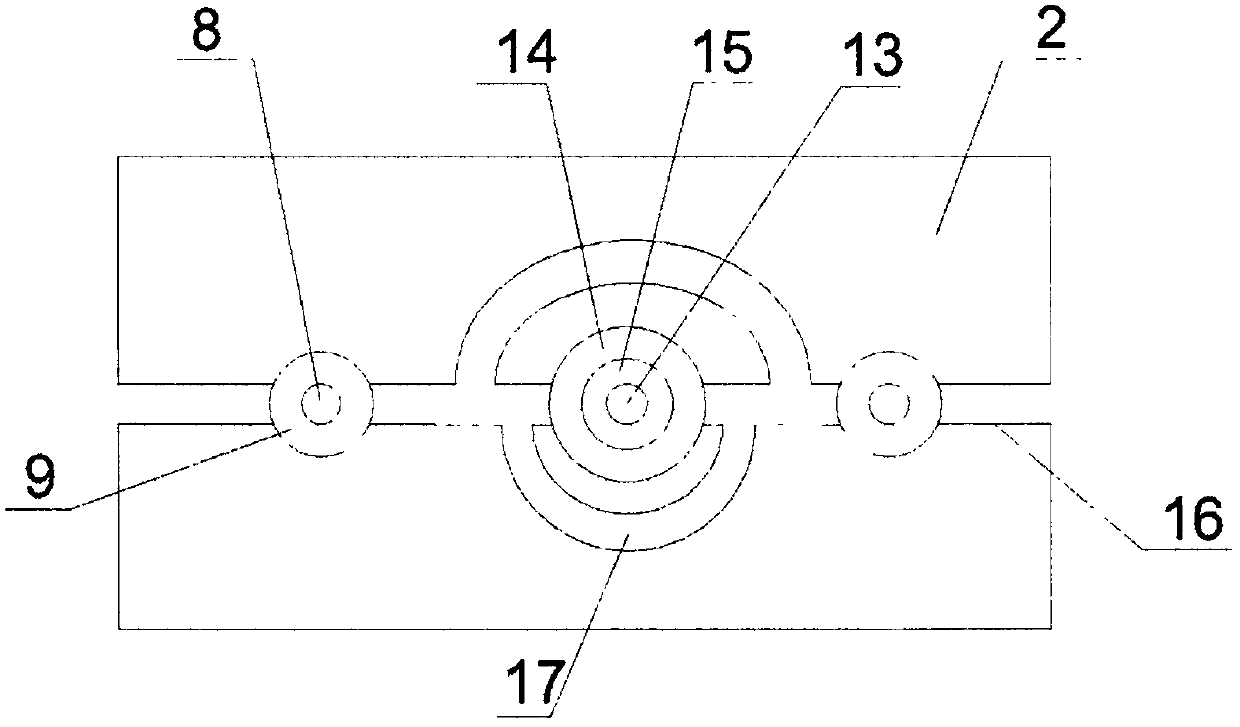

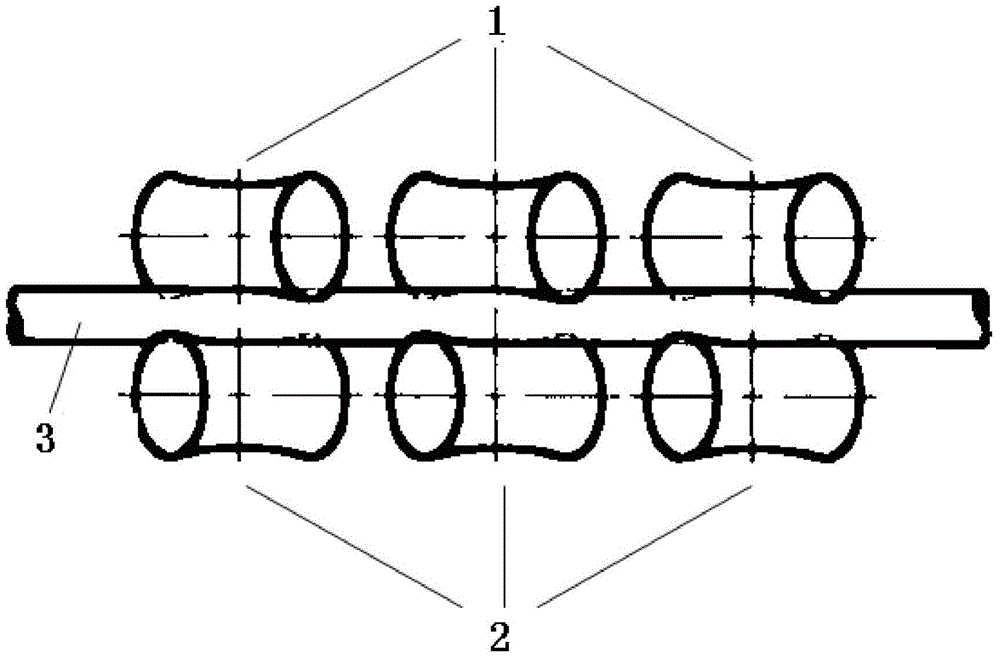

The invention provides a curvature adjustment structure for a curved-surface liquid crystal displayer. The curvature adjustment structure comprises a back plate (1), at least one double-screw bolt (3) fixedly installed on the back plate (1), a support (5) corresponding to the double-screw bolt (3), and an adjustment nut (7) in screw-thread fit with the double-screw bolt (3), wherein the two ends of the support (5) abut against the back plate (1); the double-screw bolt (3) penetrates through the support (5) and then is matched with the adjustment nut (7), the support (5) is extruded or loosened through rotation of the adjustment nut (7), the back plate (1) is extruded or loosened through the support (5), curvature adjustment of the back plate (1) is realized, so that the curvature of the curved-surface liquid crystal displayer is adjustable and is convenient to adjust, the attraction of the curved-surface liquid crystal displayer to the market can be enhanced, and the curvature adjustment structure is simple in structure and easy to realize.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

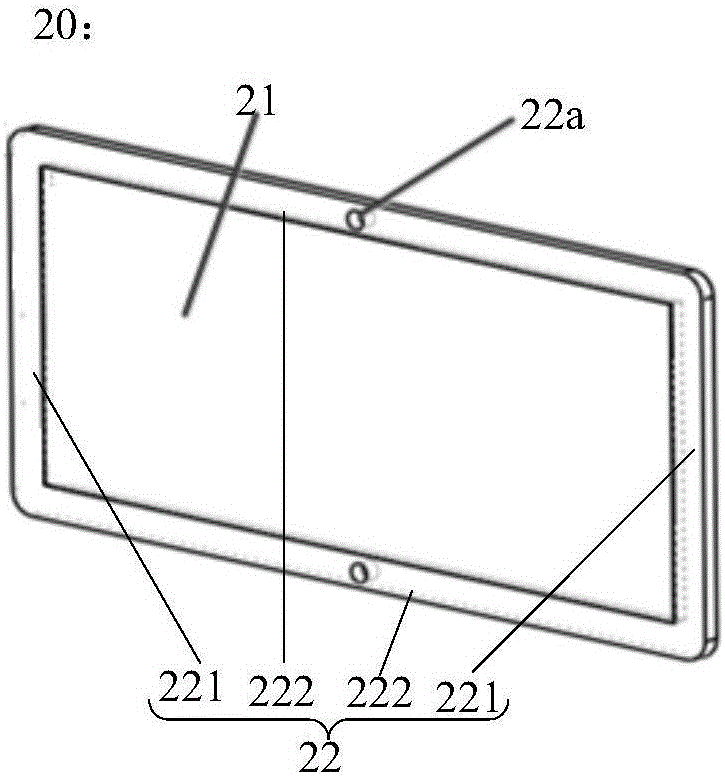

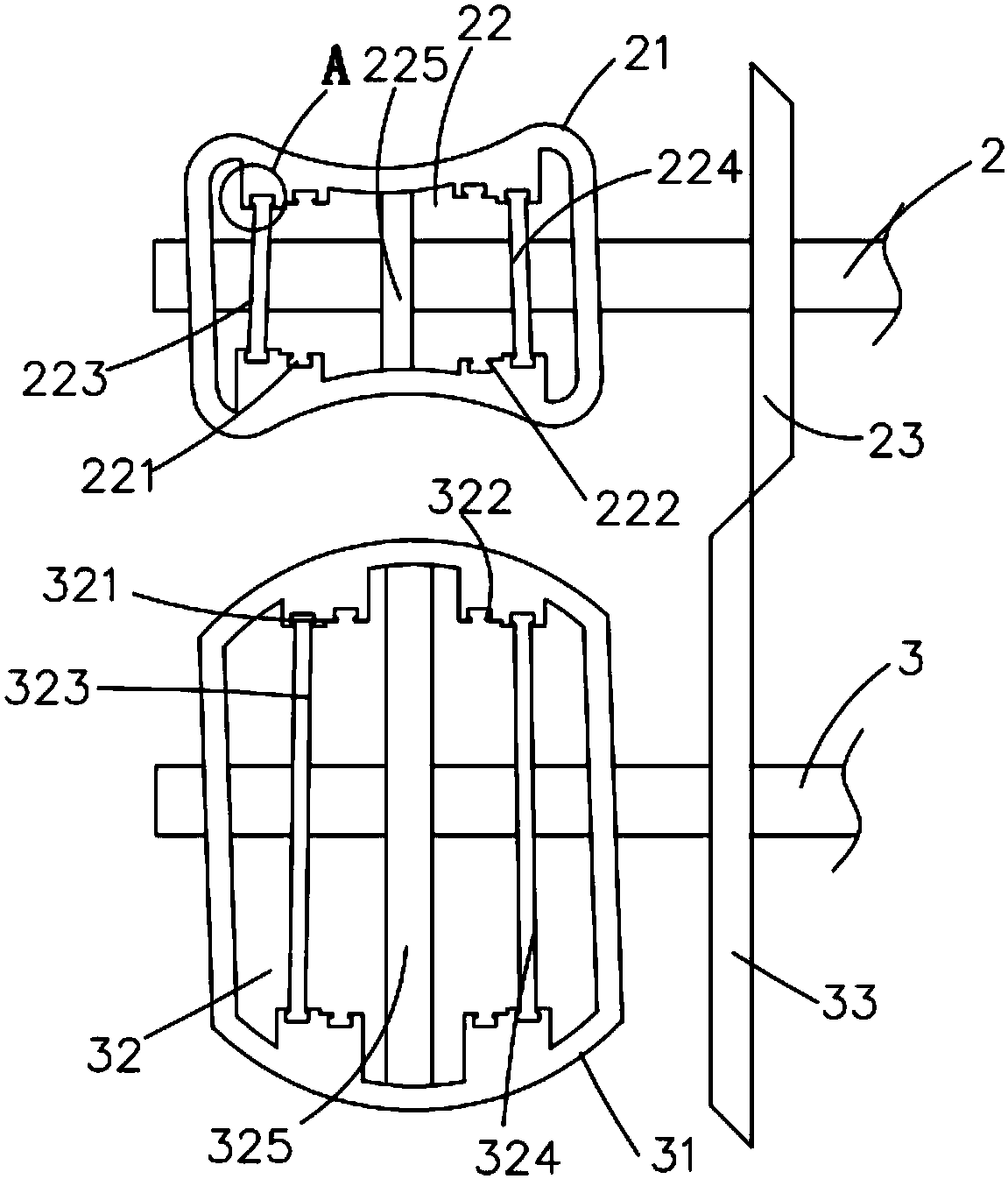

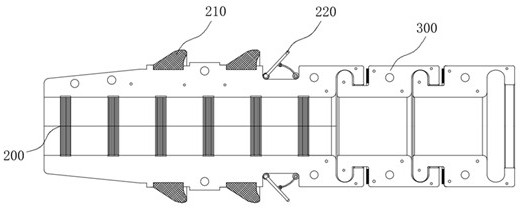

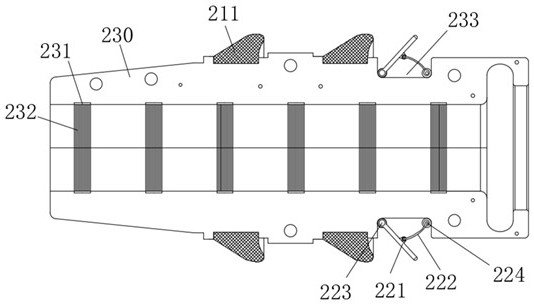

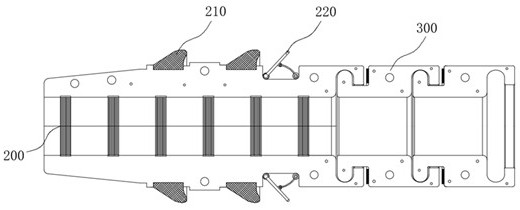

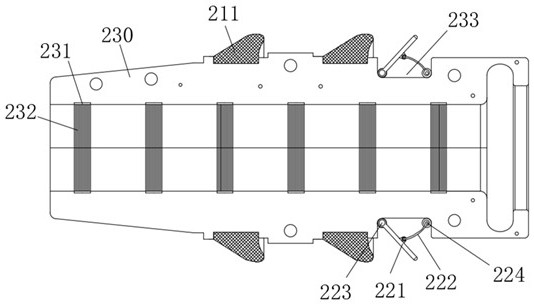

Display module and display device

InactiveCN106205395AIncreased flexibility of useImprove compatibilityOptical light guidesNon-linear opticsDisplay deviceEngineering

The invention discloses a display module and display device, pertaining to the display technology field. The display module comprises a display body composed by overlapping of a movable support structure, a display panel and a backlight module. The movable support structure surrounds the back surface and the side surface of the display body. The back side is the one away from the display panel of the backlight module. The movable support structure is formed in such a manner that multiple sub-support structures are spliced together along the arraying distribution of grating scanning direction of the display panel. Every two adjacent sub-support structures are movably connected. The display module and display device have following beneficial effects: by changing the angles of all sub-support structures, curvature of the display panel can be adjusted; flexibility and compatibility of the display module can be improved; and the display module and display device are used for displaying images.

Owner:BOE TECH GRP CO LTD +1

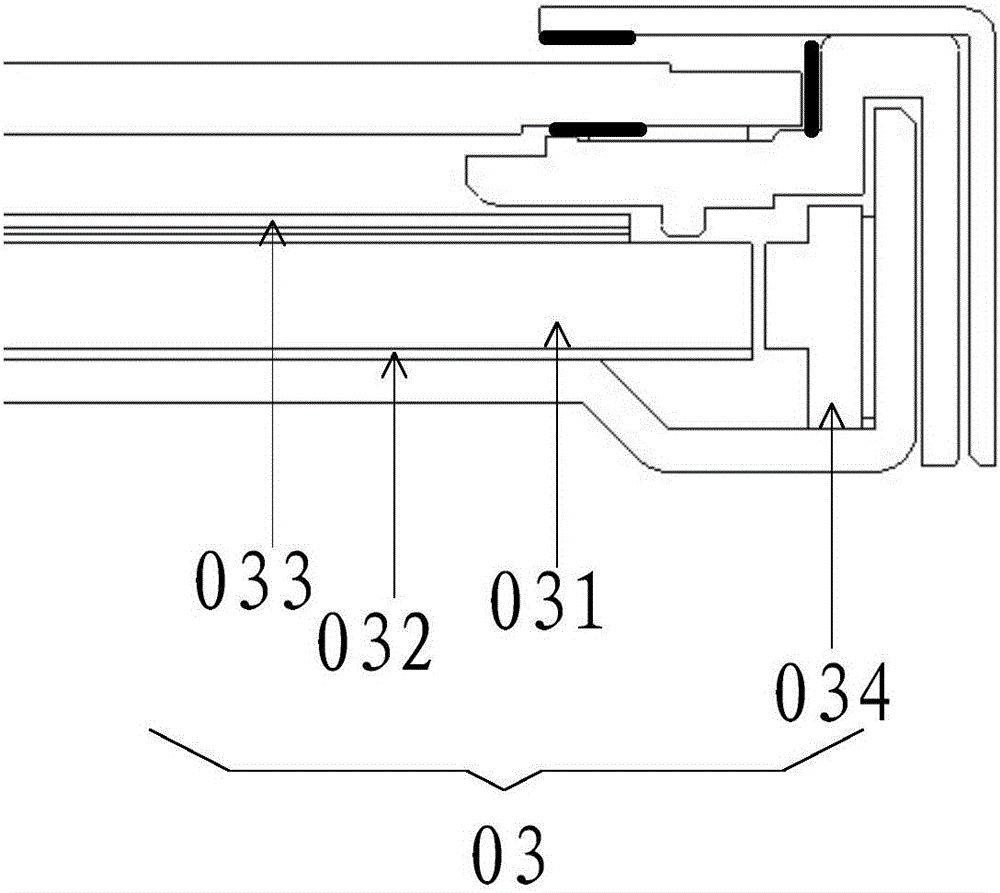

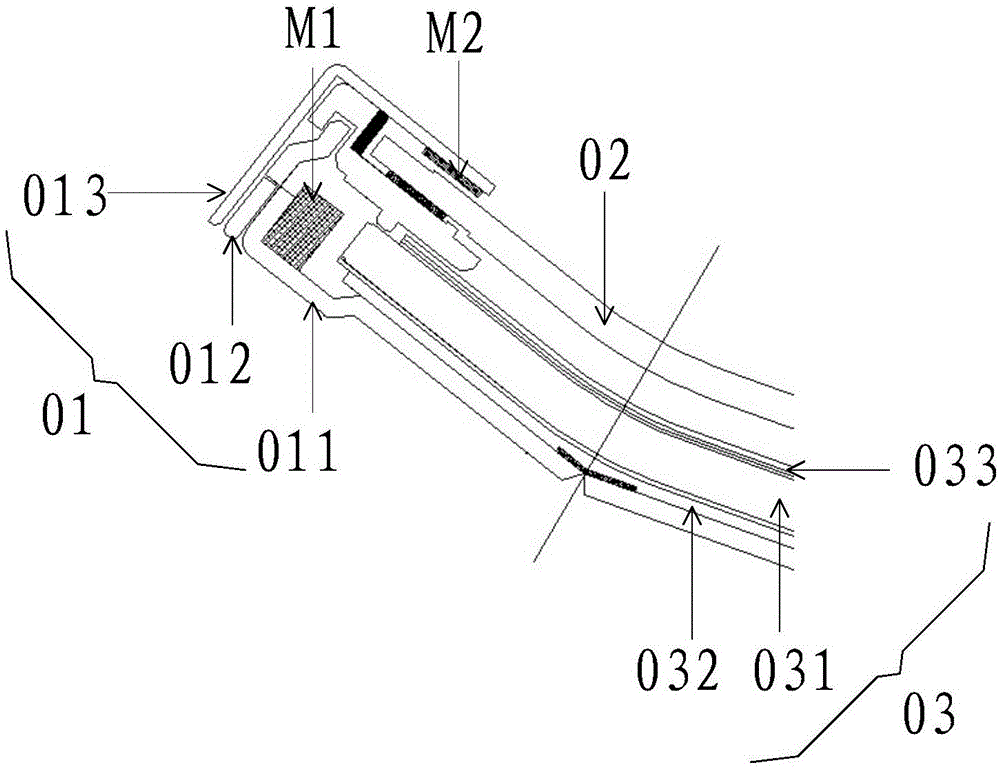

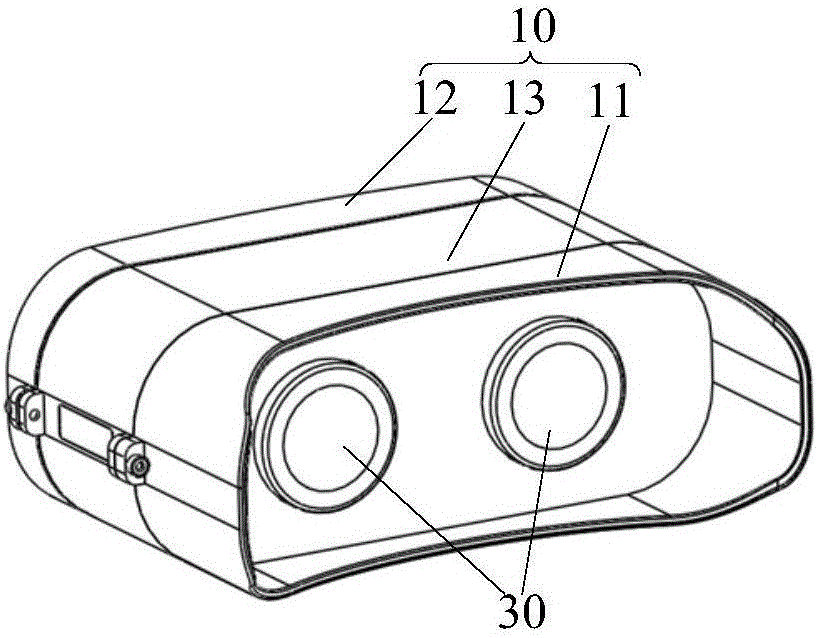

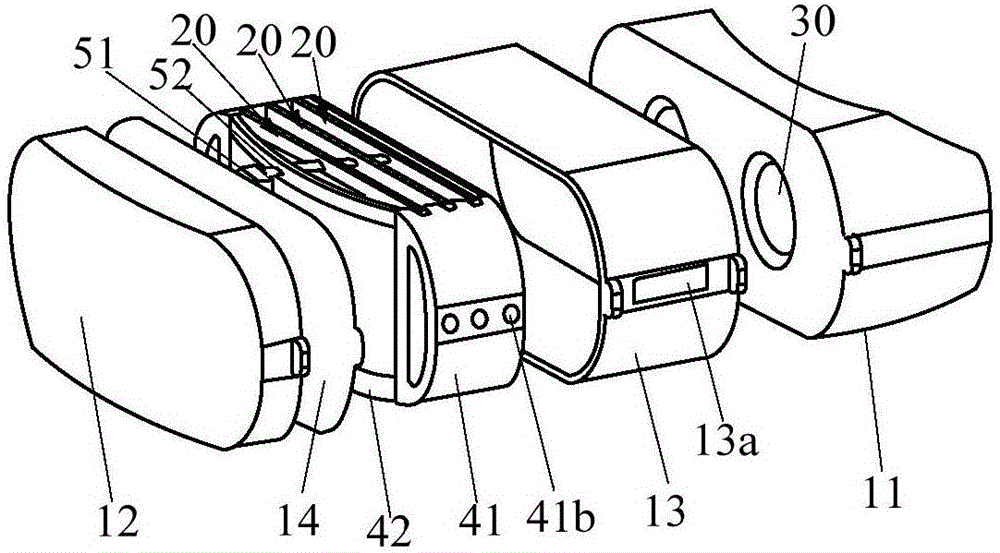

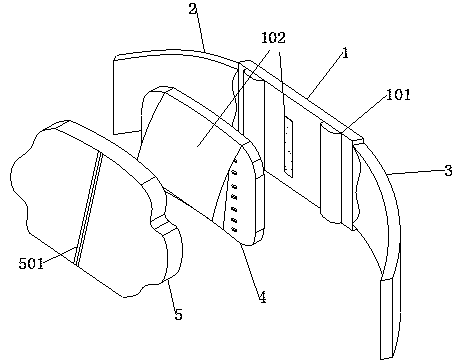

Head-mounted virtual reality equipment

ActiveCN106773060AImprove viewing experienceCurvature adjustmentCasings with display/control unitsCasings/cabinets/drawers detailsDepth of fieldVirtual reality

Owner:BOE TECH GRP CO LTD +1

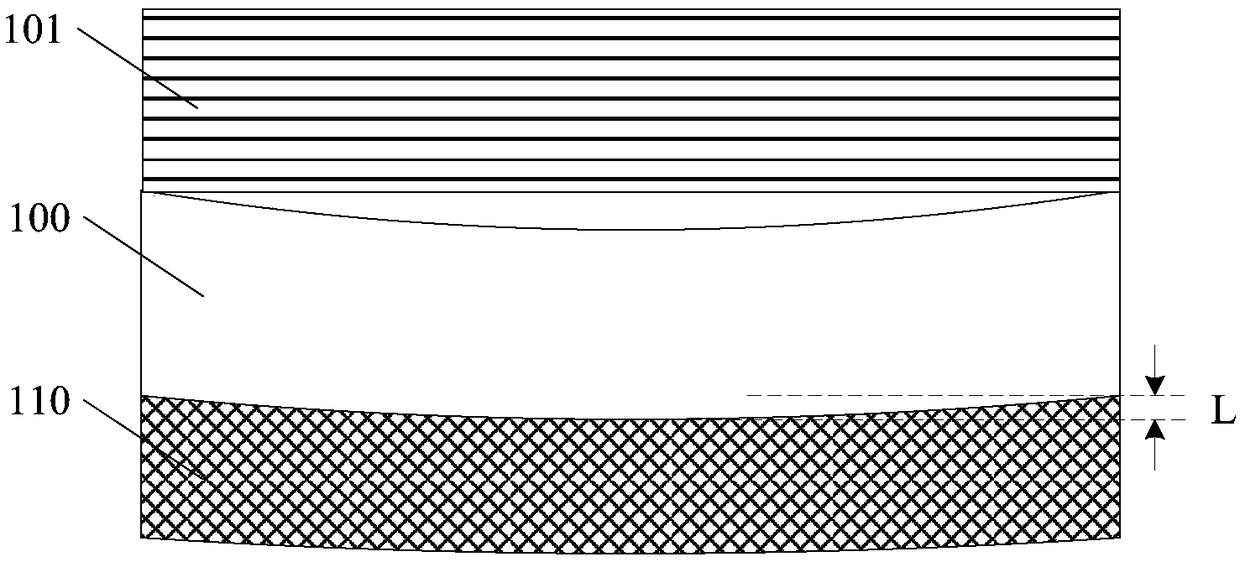

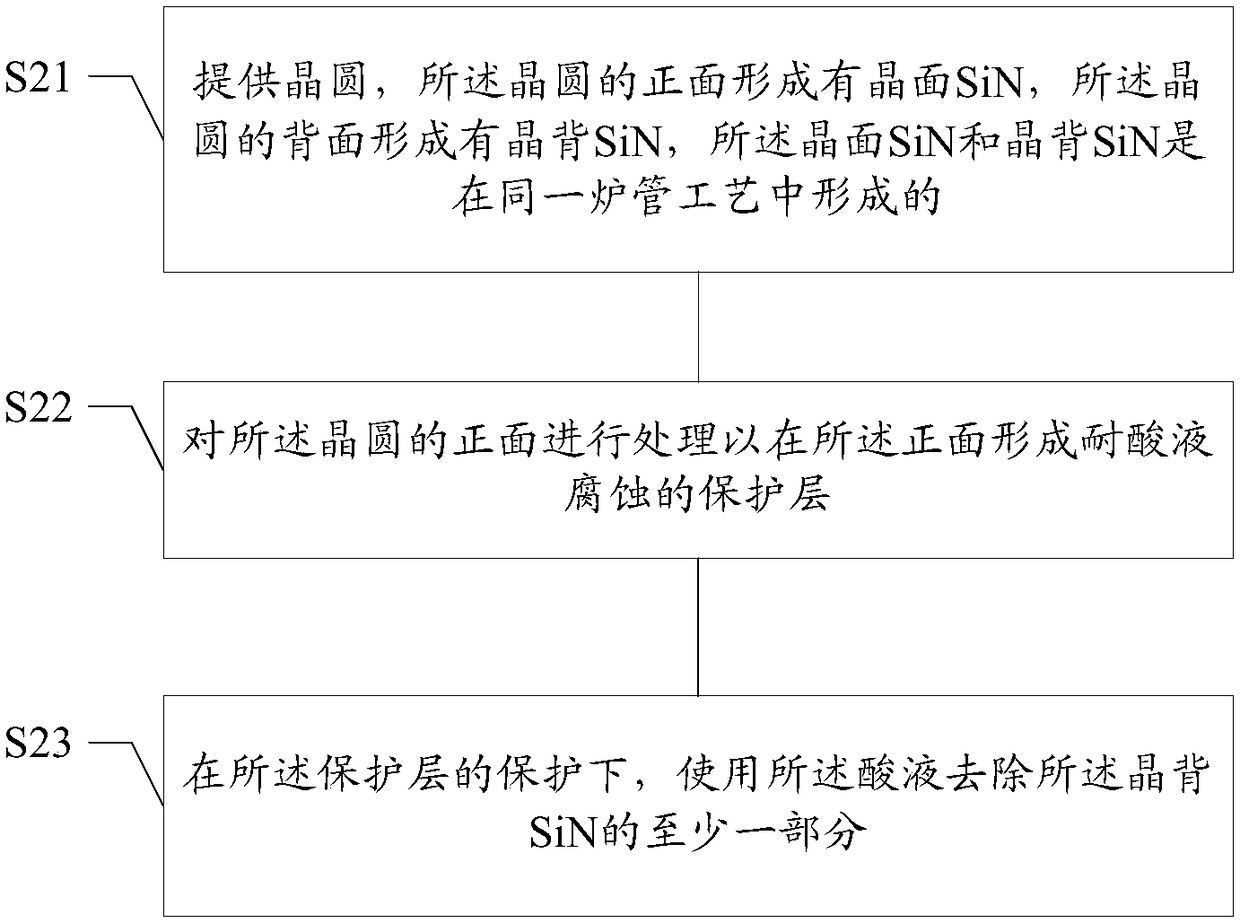

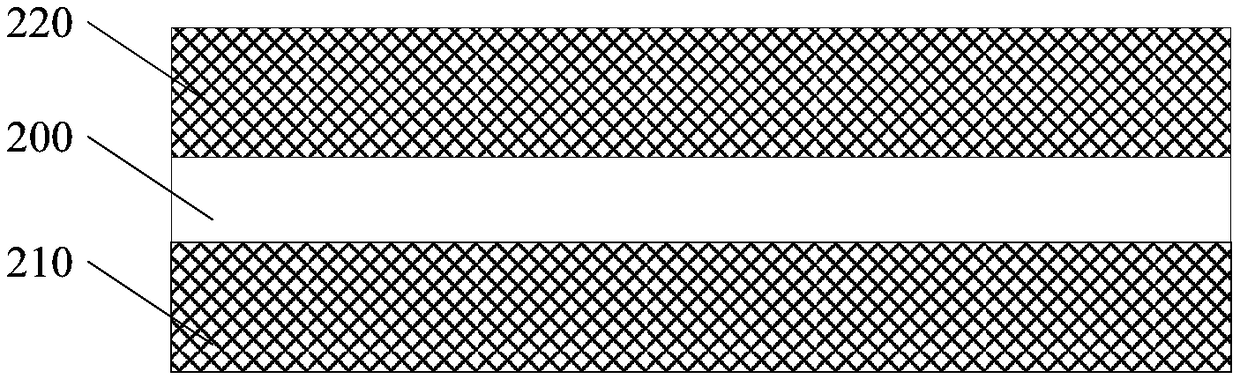

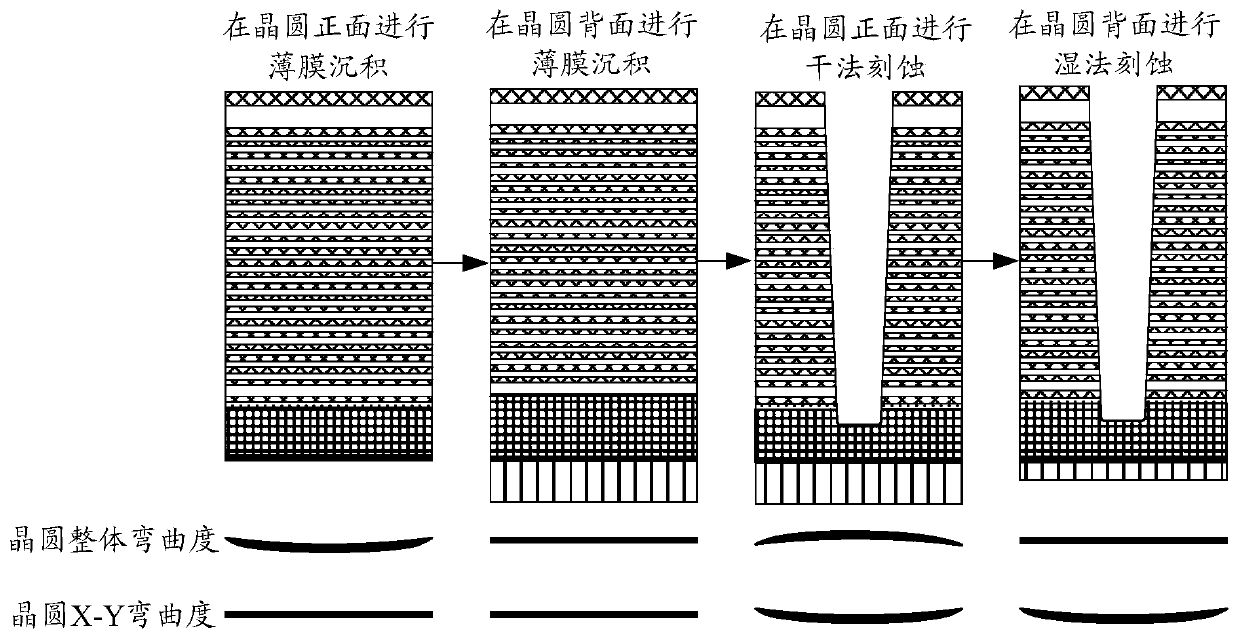

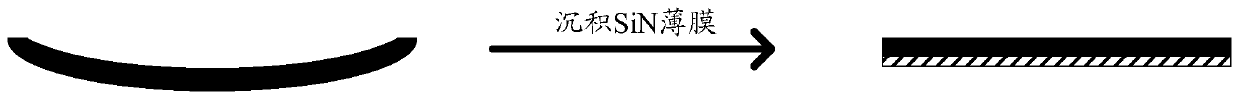

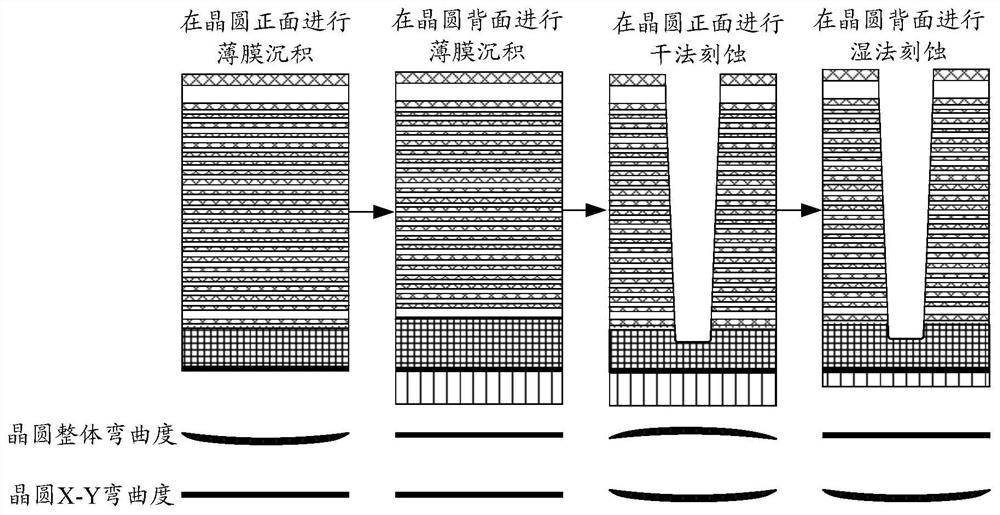

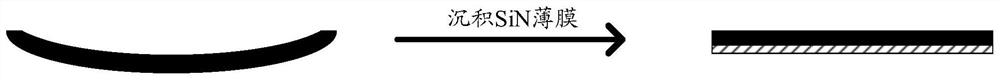

Optimization method of bending of wafer

InactiveCN108110043AQuality improvementCurvature adjustmentSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringCorrosion resistant

Provided is an optimization method of the bending of a wafer. The method includes following steps: the wafer is provided, a crystal surface SiN is formed on the front surface of the wafer, a crystal back SiN is formed at the backside of the wafer, the crystal surface SiN and the crystal back SiN are formed in the same furnace tube process, and the front surface of the wafer is processed to form anacid-corrosion-resistant protective layer on the front surface; and under the protection of the protective layer, at least a part of the crystal back SiN is removed by employing acid. According to the scheme of the method, the bending of the wafer can be adjusted, and the quality of process steps including subsequent bonding can be improved through reduction of adjustment of the bending of the wafer.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

Artificial turf bent filament and preparation method thereof

InactiveCN105926078AImprove aging resistanceImprove wear resistanceMelt spinning methodsConjugated synthetic polymer artificial filamentsWater bathsAging resistance

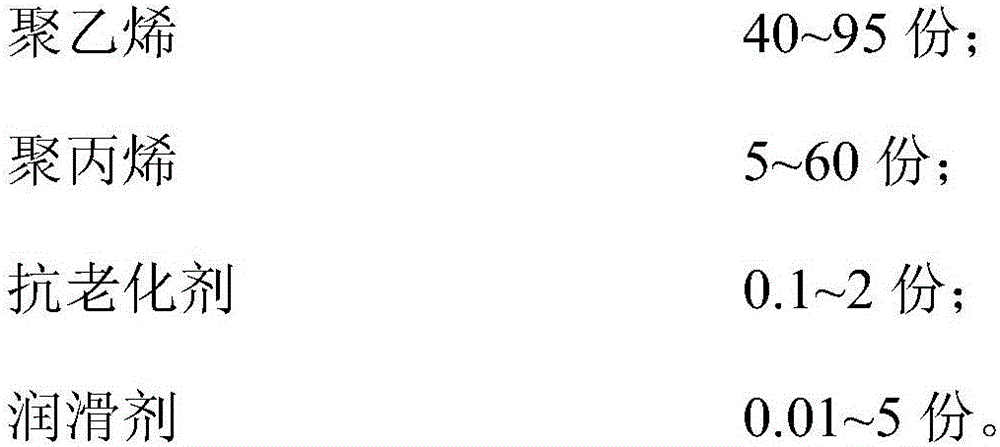

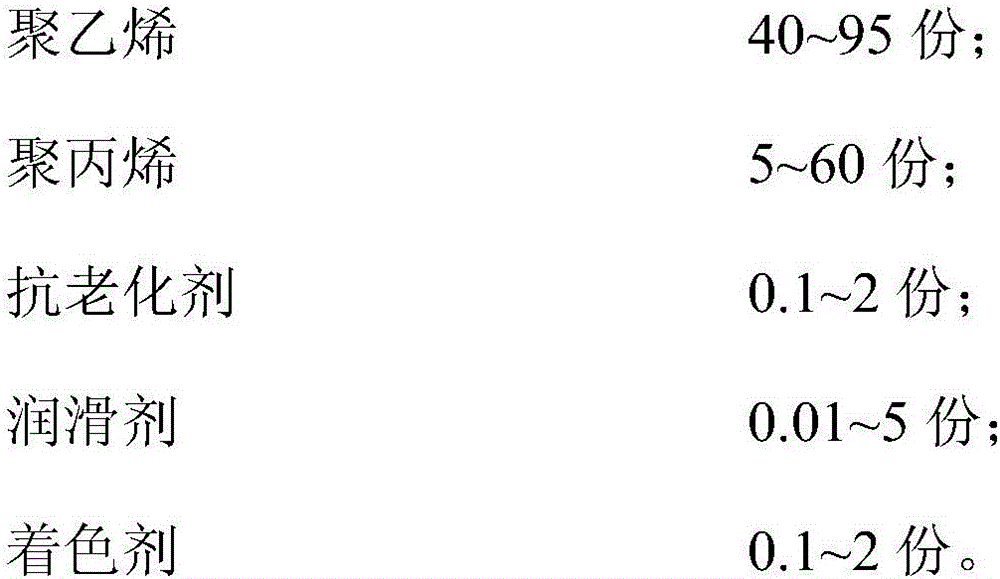

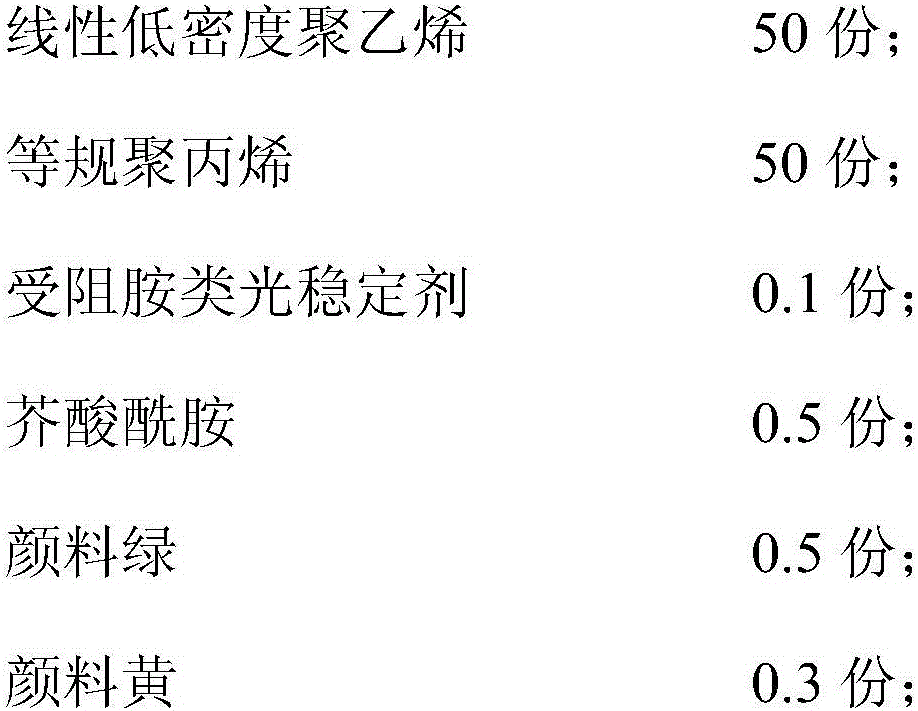

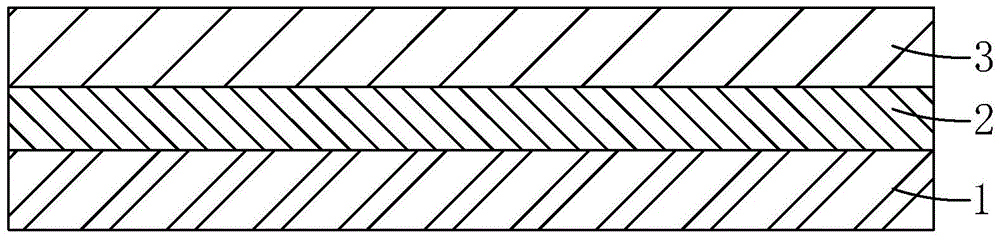

The invention discloses an artificial turf bent filament and a preparation method thereof, wherein the artificial turf bent filament comprises the components of 40-95 parts of polyethylene, 5-60 parts of polypropylene, 0.1-2 parts of antiaging agent and 0.01-5 parts of lubricant in parts by weight; the preparation method comprises the steps of 1) preparing the materials: weighing, mixing and melting the materials; 2) extruding: extruding the melt materials into a metering pump; 3) forming a monofilament: quantitatively feeding the materials to a spinning die head through the metering pump, spraying the monofilament, leading the monofilament to a drawing machine; 4) drawing: drawing the monofilament by the draft ratio of 3-6 times; 5) cooling: putting the drawn monofilament in a water bath; 6) preheating: preheating the cooled monofilament through a first heat roller and a second heat roller; 7) air deforming: bending the preheated monofilament for deformation, so as to obtain the artificial turf bent filament. The artificial turf bent filament is soft and comfortable, has a good touch feeling, and has the characteristics of sun block and aging resistance.

Owner:GUANGZHOU AOSHENG ARTIFICIAL STRAW CO LTD

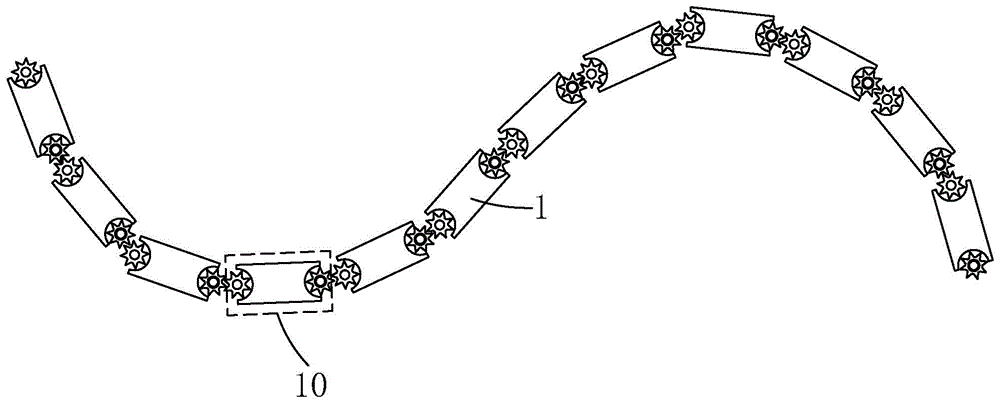

Curvature-adjustable display device

ActiveCN105702168ACurvature adjustmentCurvature intelligent adjustmentIdentification meansDisplay deviceEngineering

The invention provides a curvature-adjustable display device which comprises a backboard, a flexible display panel arranged on the backboard and a curvature control module. The backboard comprises a plurality of backboard units connected end to end. Each backboard unit comprises a connecting plate, a driving gear and a driven gear, wherein the driving gear and the driven gear are fixed to the two ends of the connecting plate respectively. Every two adjacent backboard units are connected through the corresponding driving gear and the corresponding driven gear which are meshed with each other. The rotating actions of the driving gears in the backboard units can be independently controlled through the curvature control module. The backboard is presented in a specific shape by adjusting the rotating amounts of the driving gears in the backboard units respectively, so that the flexible display panel is presented in a specific curvature along with the backboard, and thus the curvature of the display device is adjusted; the structure is simple, the thickness is small, and the curvature of the display device can be intelligently adjusted.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

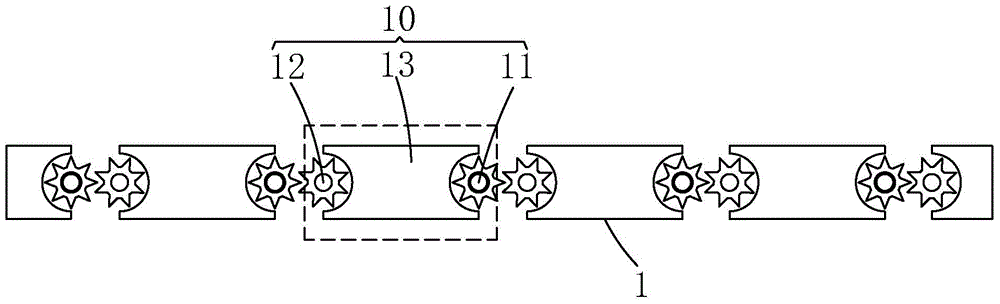

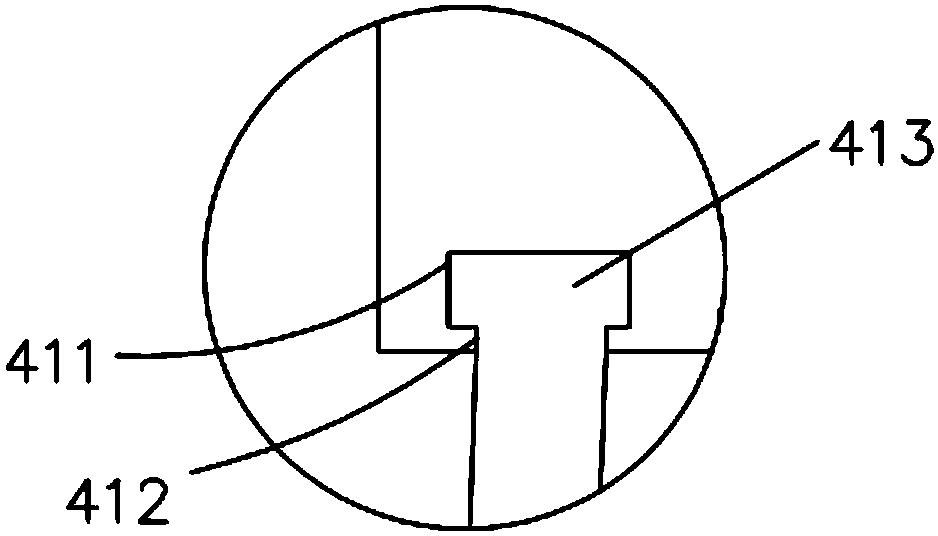

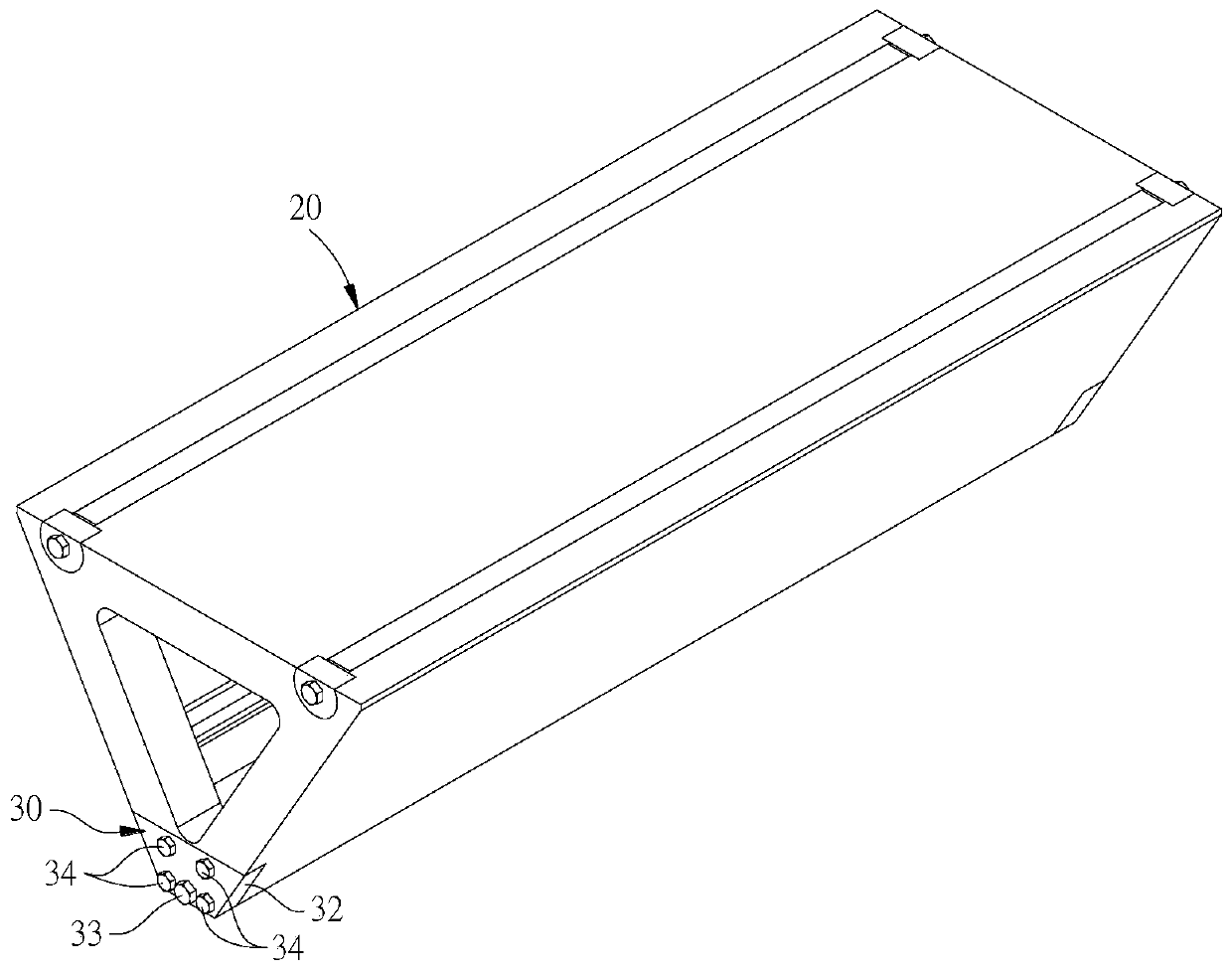

Flanging and circle-cutting all-in-one machine

ActiveCN108145439AImprove work performanceImprove machining accuracyOther manufacturing equipments/toolsEngineeringFlanging

The invention discloses a flanging and circle-cutting all-in-one machine comprising a machine station, and a centering component, a controllable pitch component and a shearing component which are arranged on the machine station. The shearing component comprises a gear motor, an upper cutter shaft and a lower cutter shaft, and the upper cutter shaft and the lower cutter shaft are arranged in parallel, and driven by the gear motor to rotate; the rotation directions of the upper cutter shaft and the lower cutter shaft are opposite, and the end of the upper cutter shaft is provided with a first squeezing roller and a first cutter; the circumference of the first squeezing roller is sunken inward, and the end of the lower cutter shaft is provided with a second squeezing roller and a second cutter; the circumference of the second squeezing roller protrudes outward, and the position of the first squeezing roller is corresponding to the position of the second squeezing roller; and the positionof the first cutter is corresponding to the position of the second cutter. Compared with the prior art, the all-in-one machine disclosed by the invention has the advantages of stable working performance and high machining precision by arrangement of relevant structures.

Owner:湖南省辰波建设有限公司

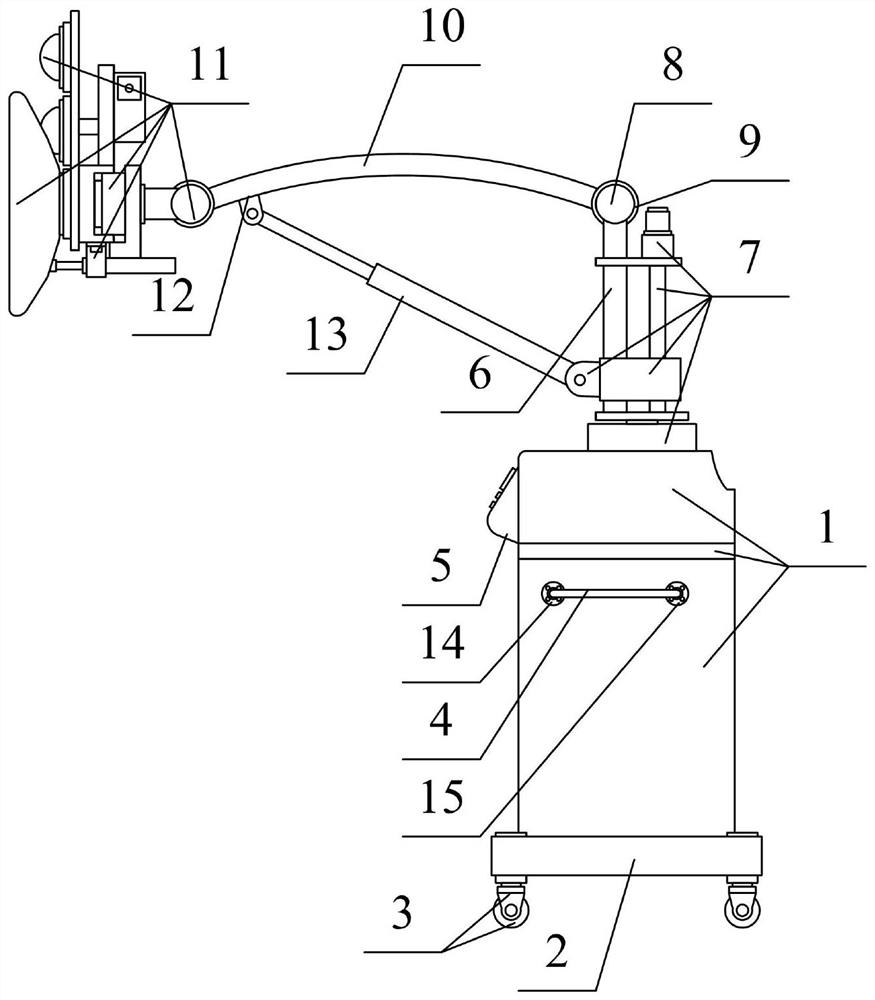

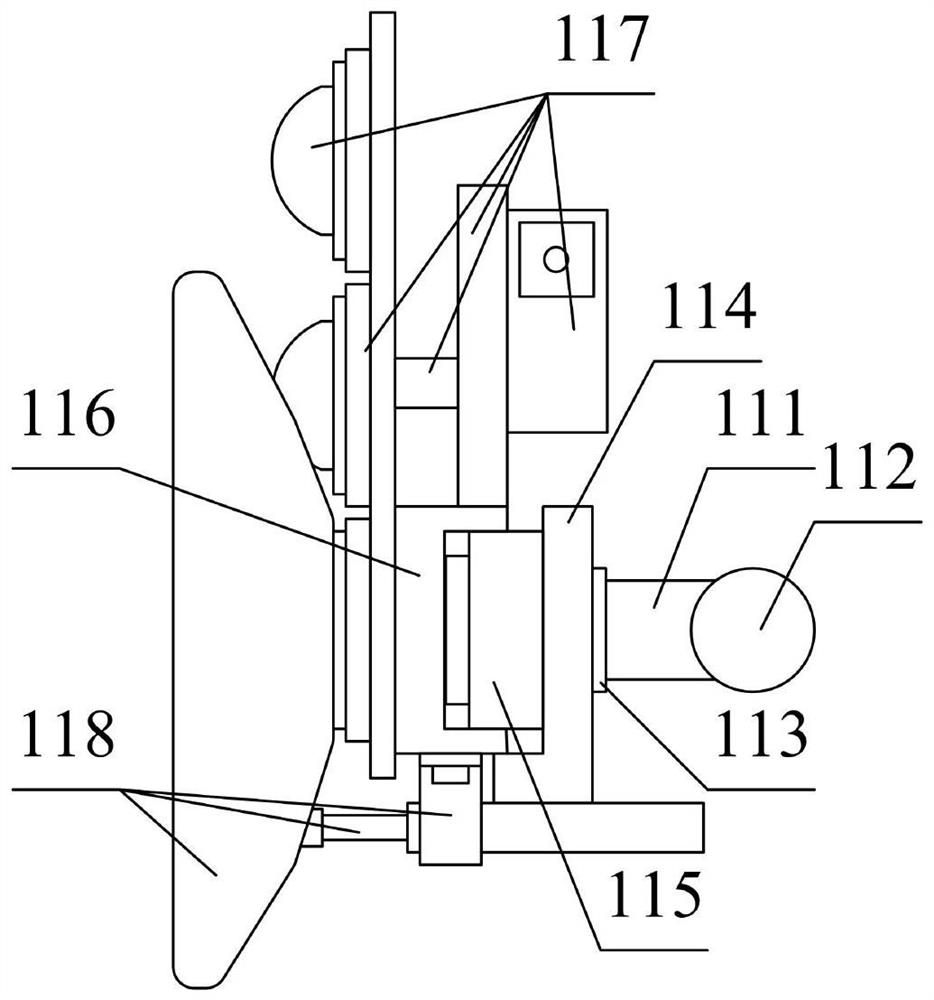

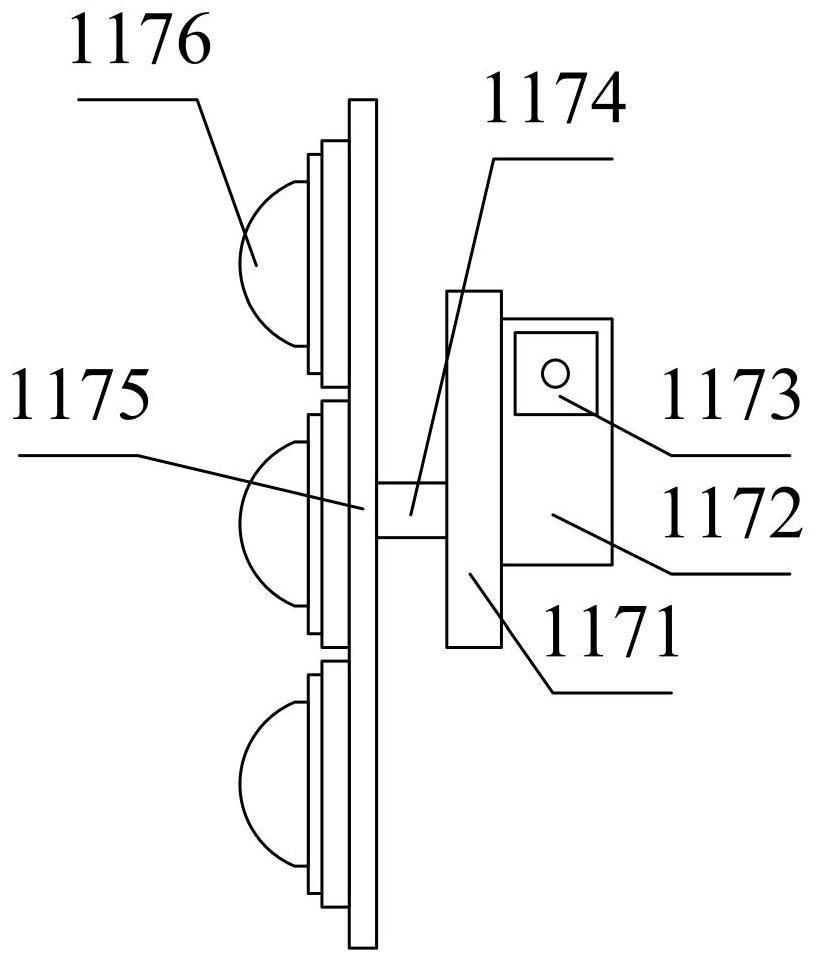

Multifunctional light therapeutic apparatus for dermatology

The invention provides a multifunctional light therapeutic apparatus for dermatology. The multifunctional light therapeutic apparatus comprises a machine body, a base, translation wheels, a grasping rod, a control panel, a stand column, a lifting assembly disc structure, a first connecting disc, a second connecting disc, a bent arm, a machine head adjusting and replacing structure, a first U-shaped seat, an inclined electric cylinder, a first assembly column and a second assembly column, wherein the base is mounted at the lower end of the machine body through a bolt; besides, the translation wheels are mounted on the periphery in the base through bolts; the first assembly column and the second assembly column are welded to the left side and the right side of the rear end of the grasping rod correspondingly, and the first grasping column and the second grasping column are mounted on the left side and the right side of the upper side of the front surface of the machine body through bolts correspondingly; and the control panel is mounted at the upper part of the left surface of the machine body through bolts. The multifunctional light therapeutic apparatus has the beneficial effects that the machine head adjusting and replacing structure is arranged, and different light sources are matched for connection and replacement for use.

Owner:李丽

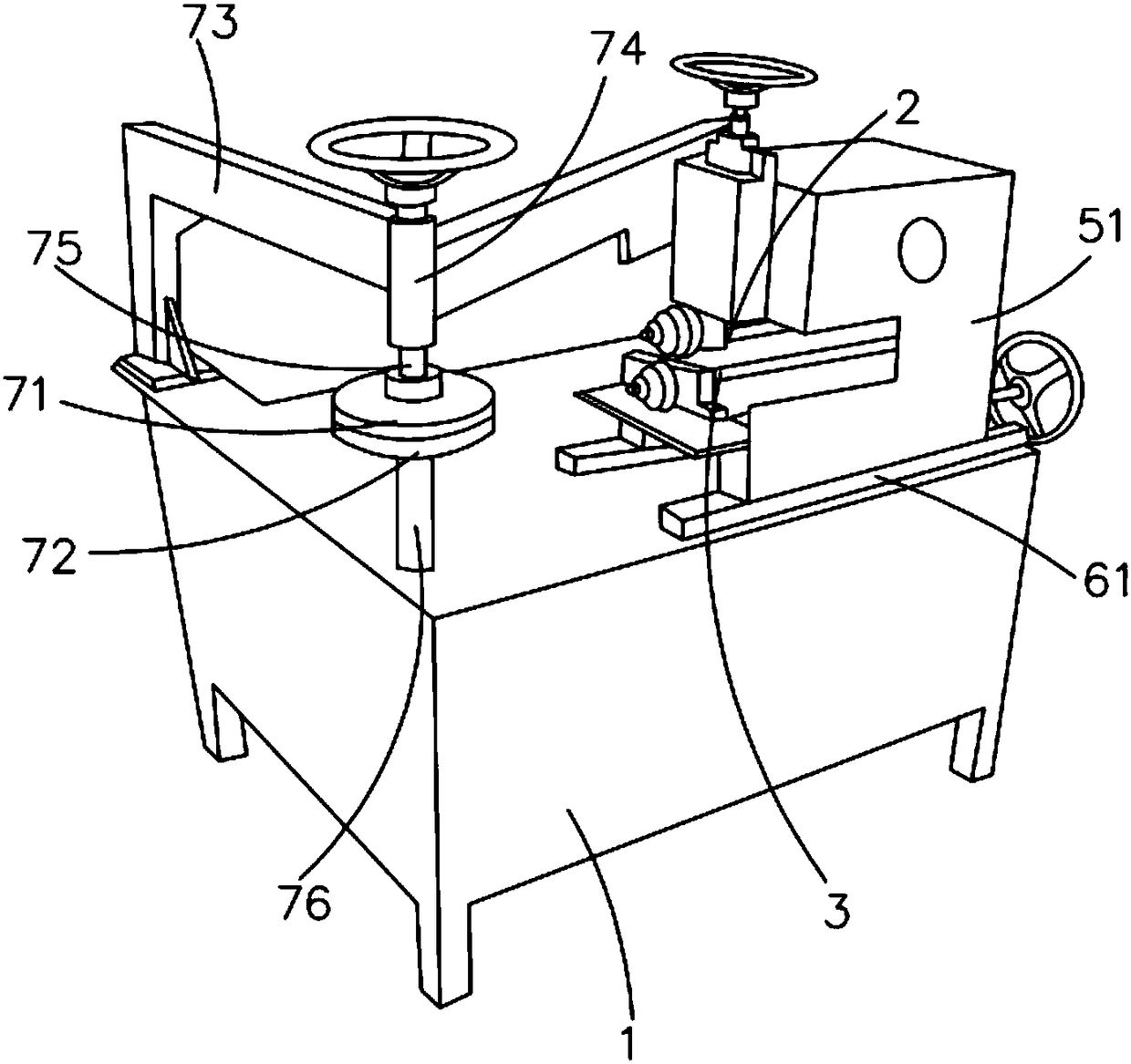

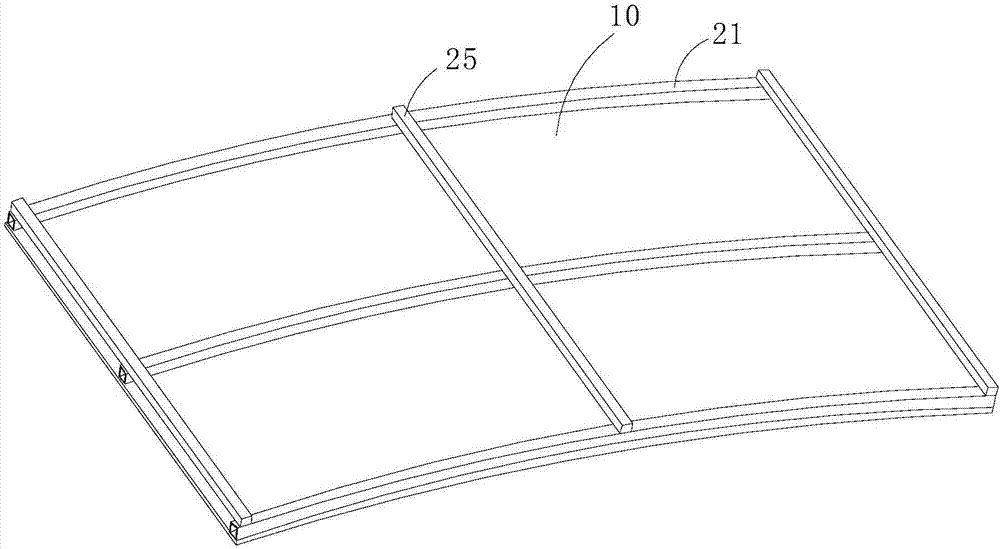

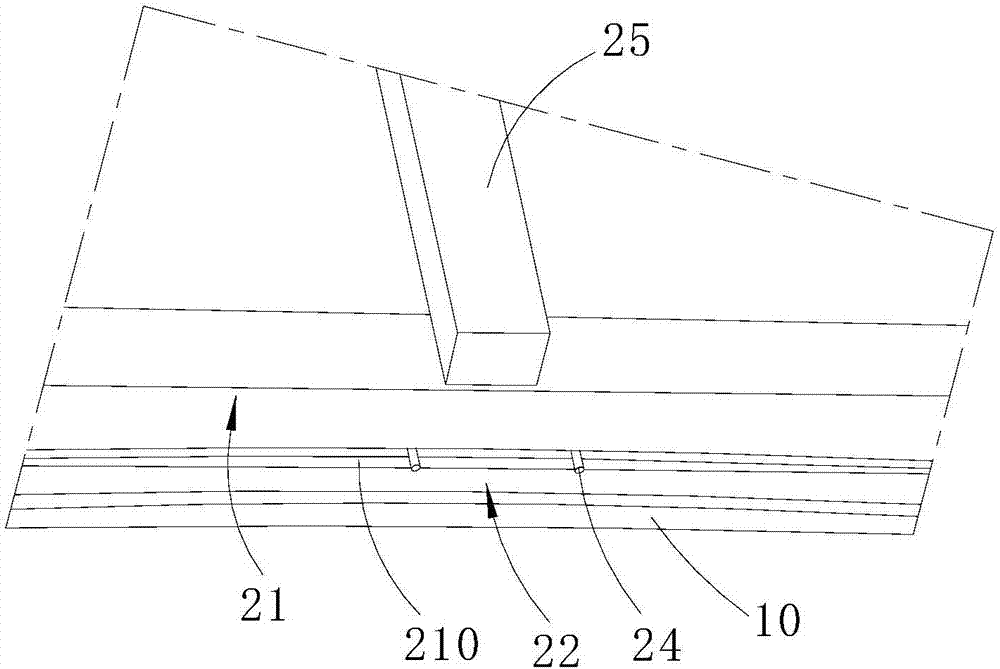

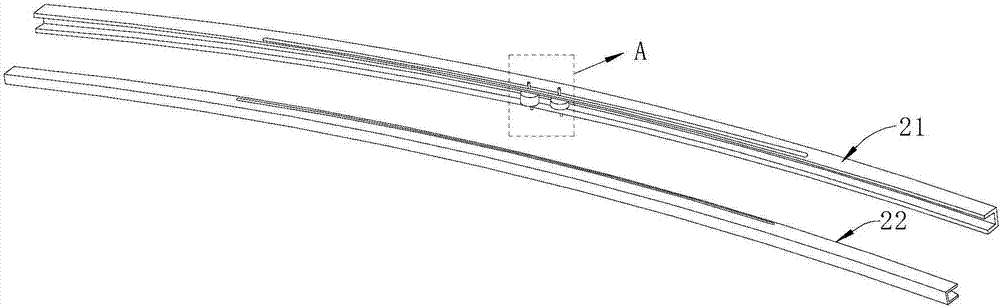

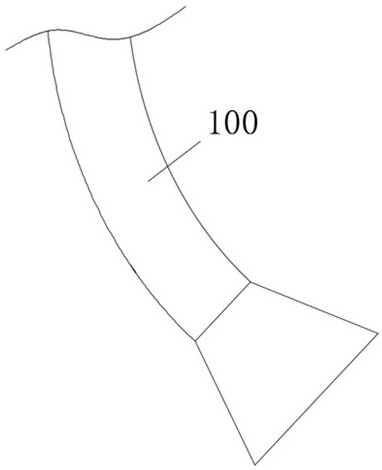

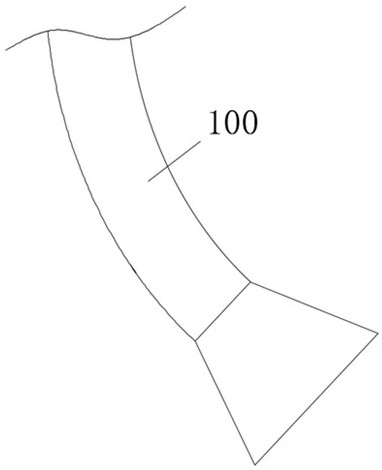

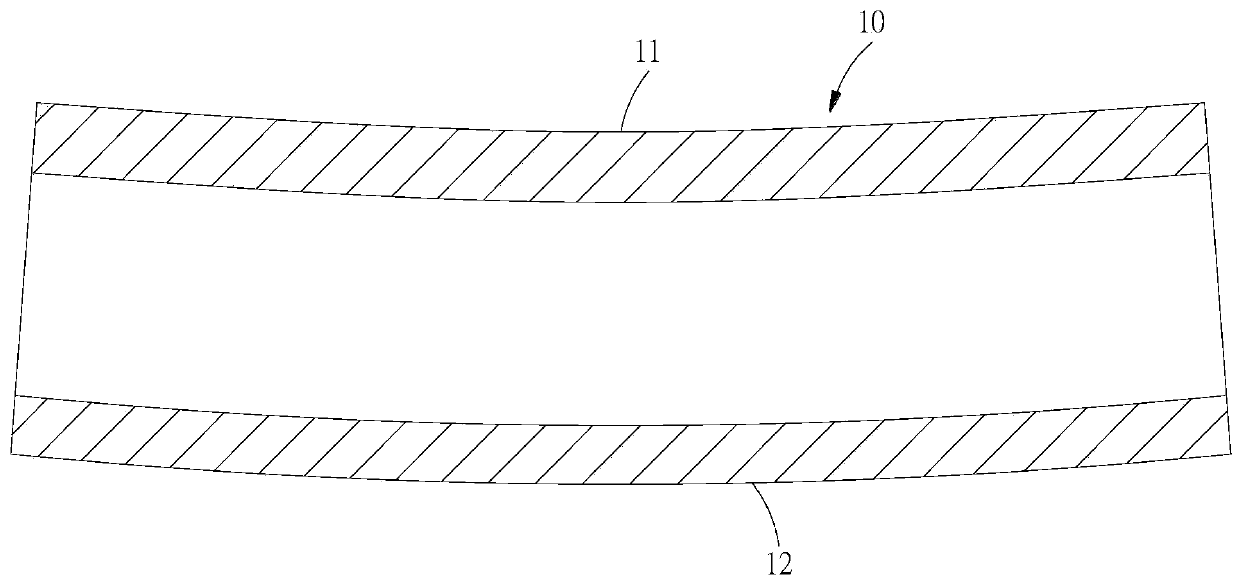

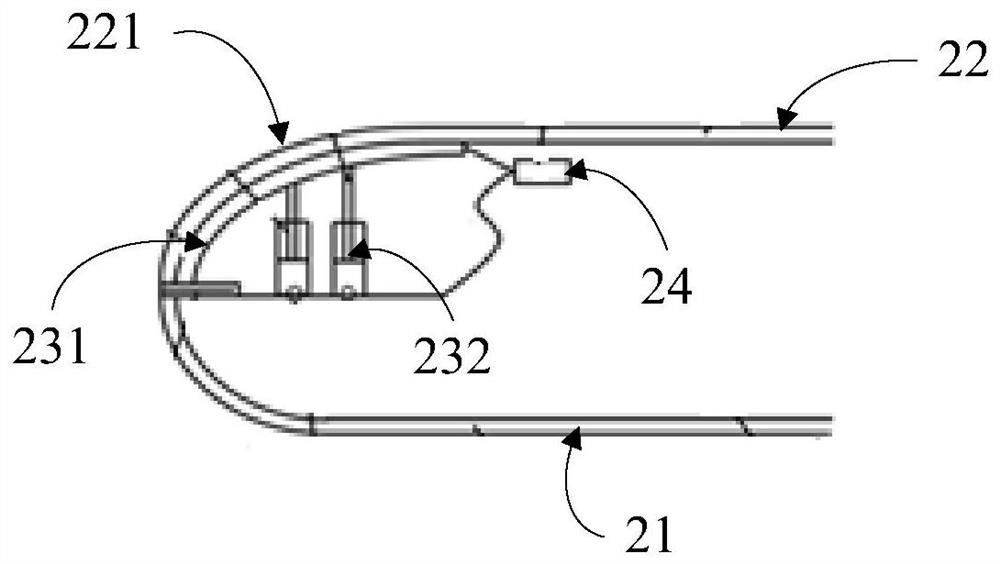

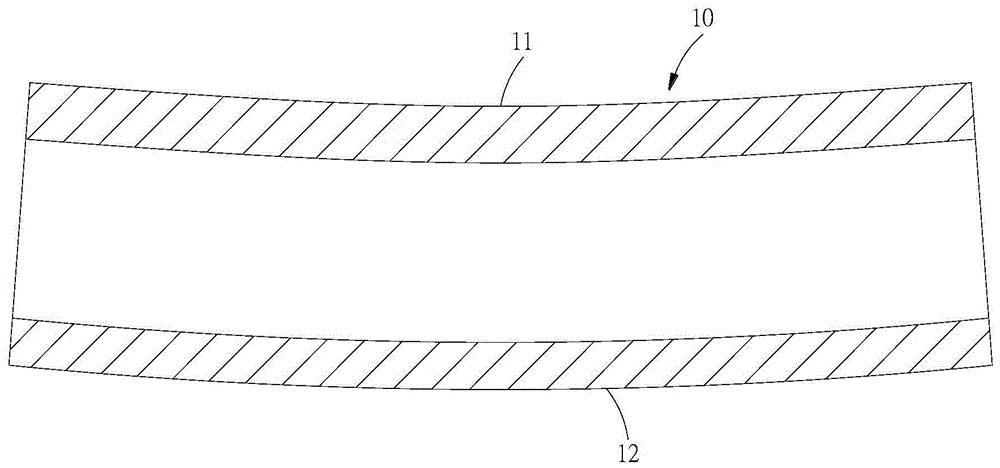

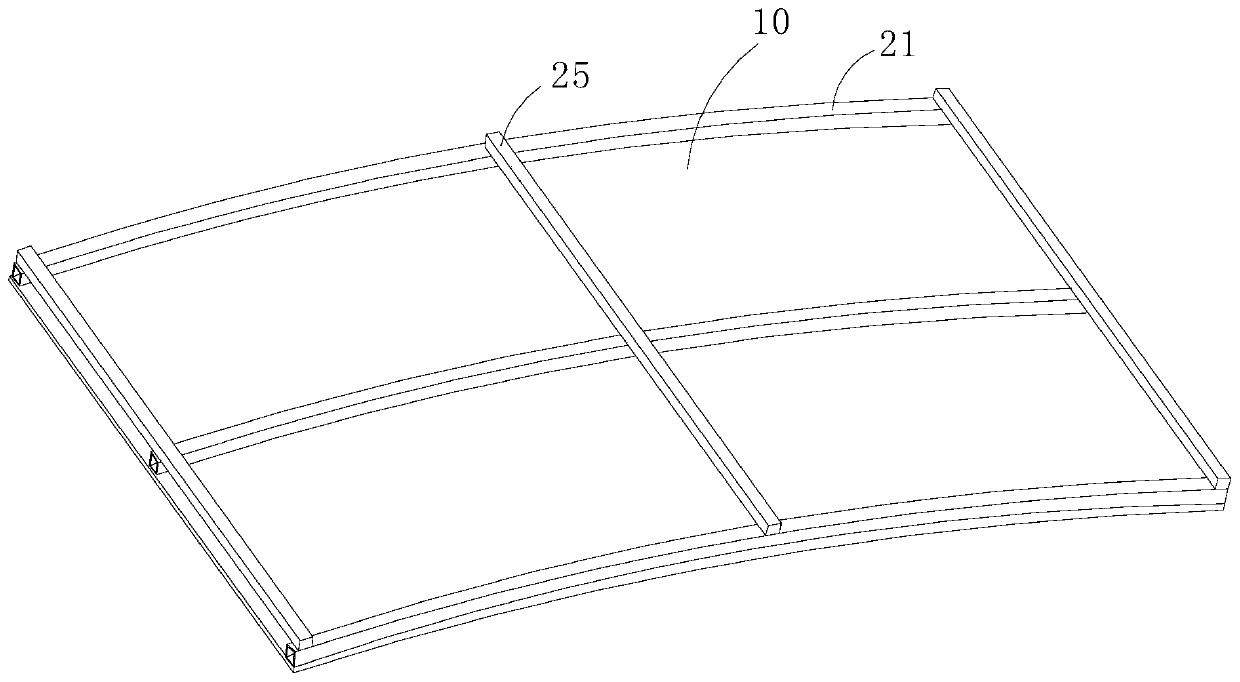

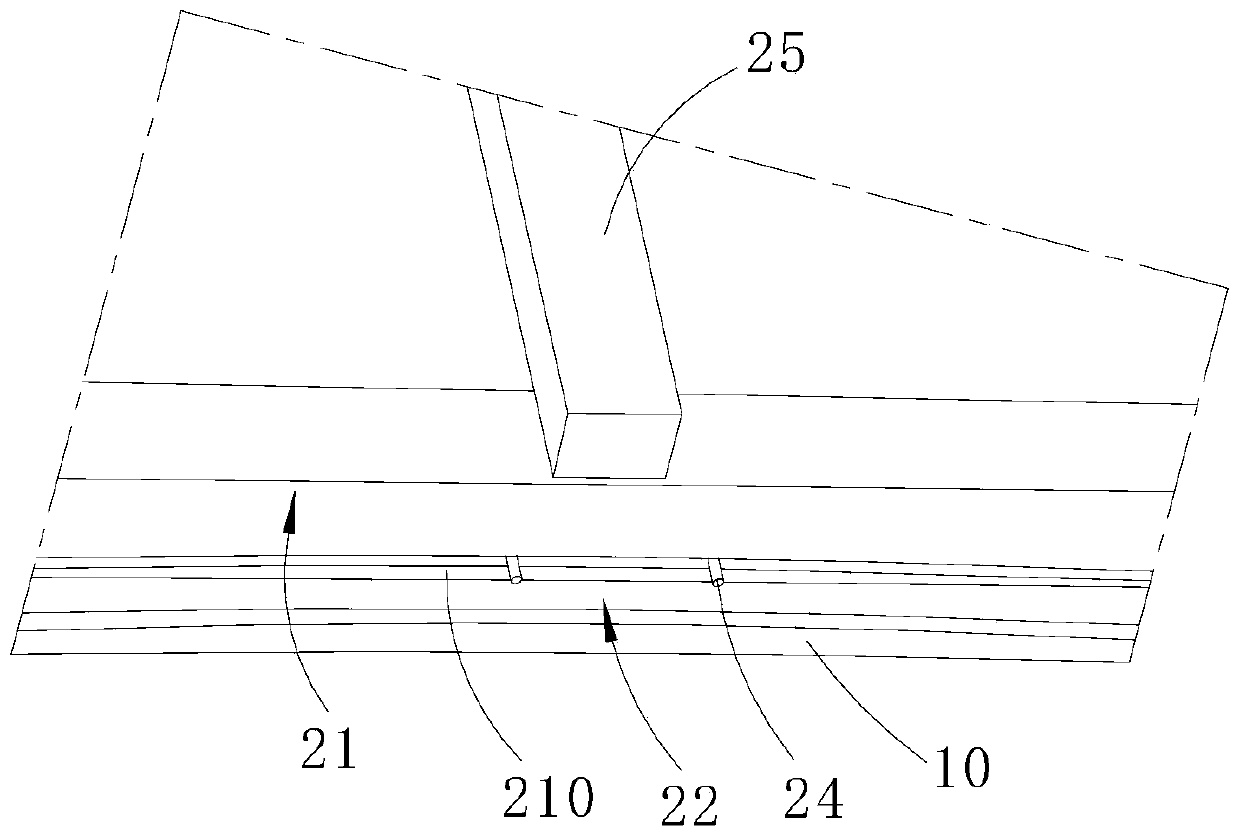

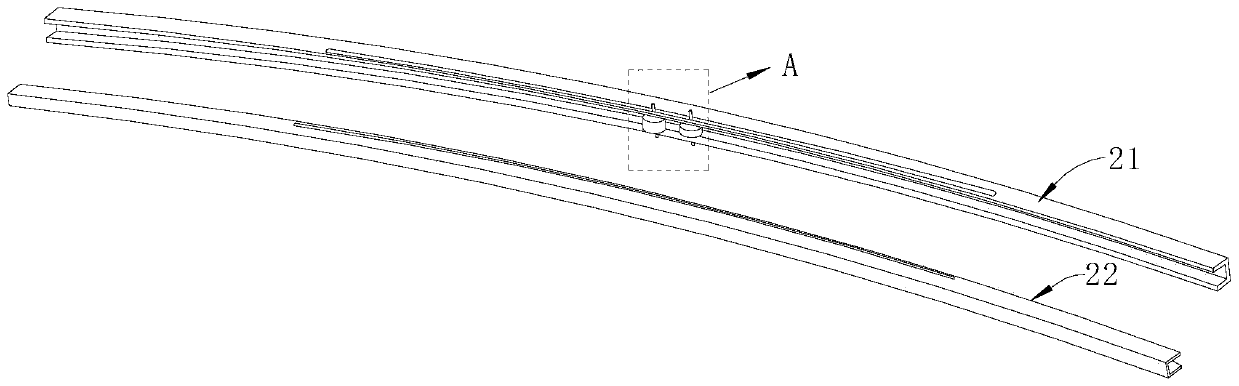

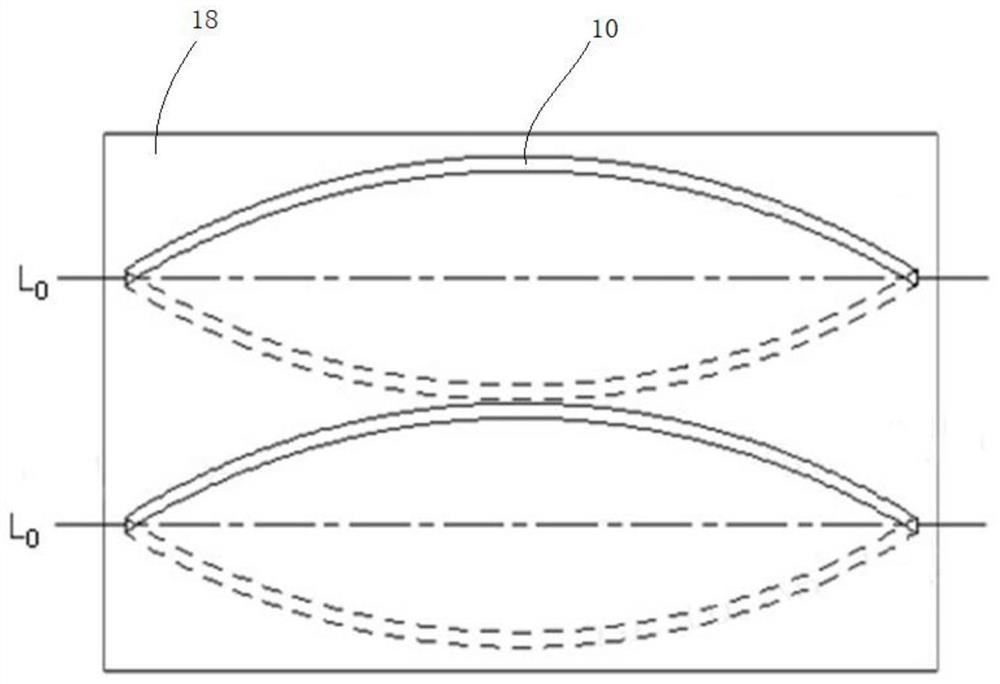

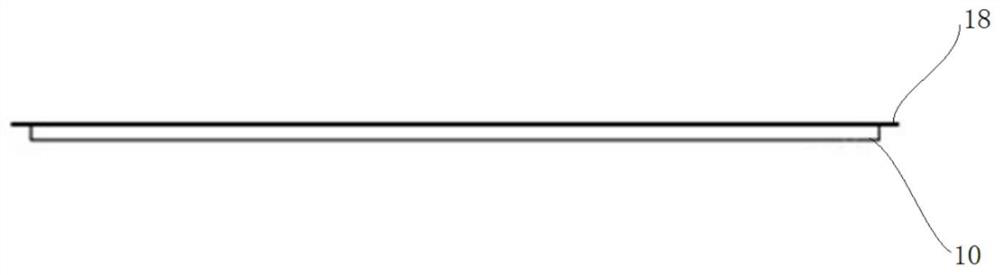

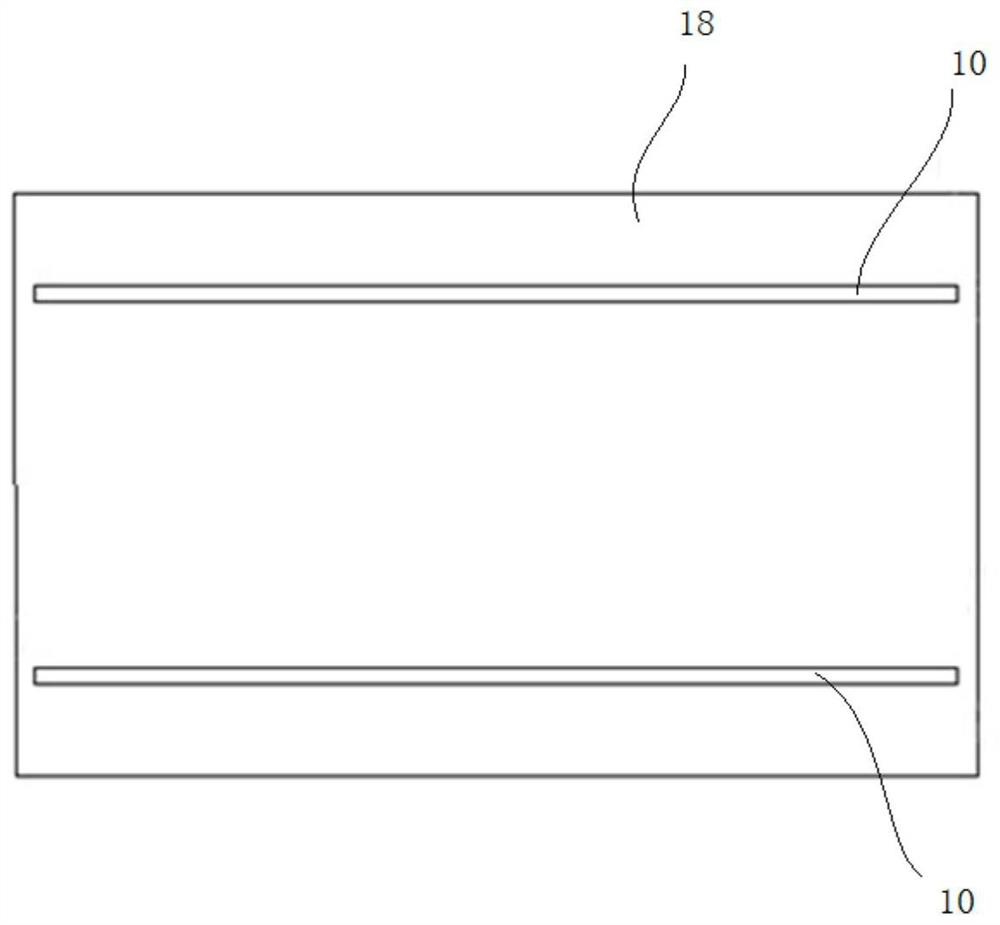

Curved-surface displayer and curvature adjusting mechanism thereof

ActiveCN107464504ACurvature adjustmentMeet the needs of the display experienceIdentification meansDisplay deviceEngineering

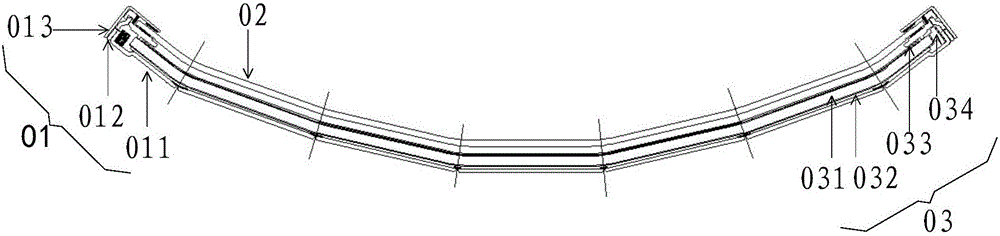

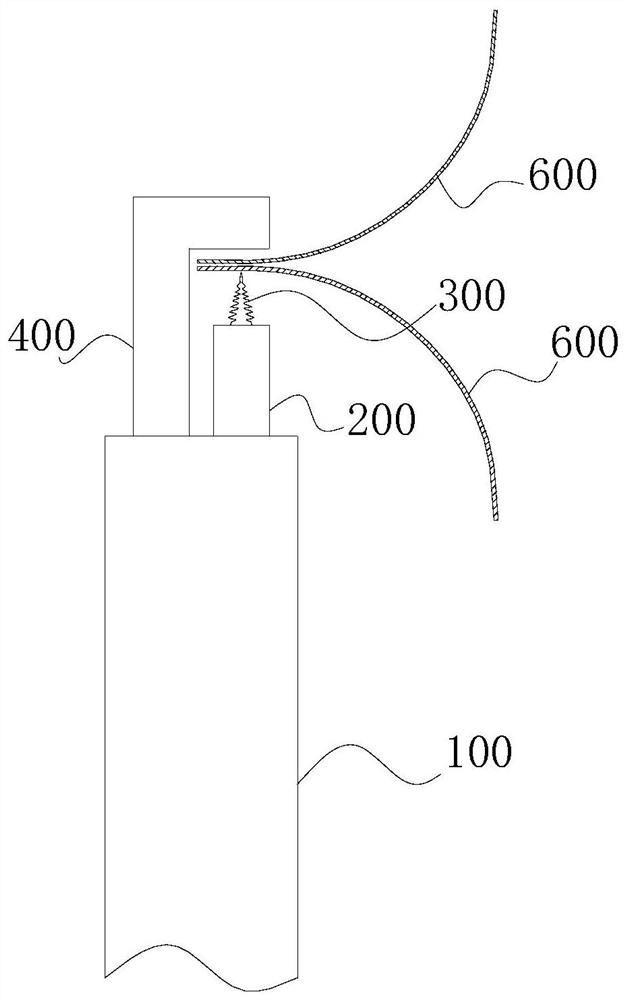

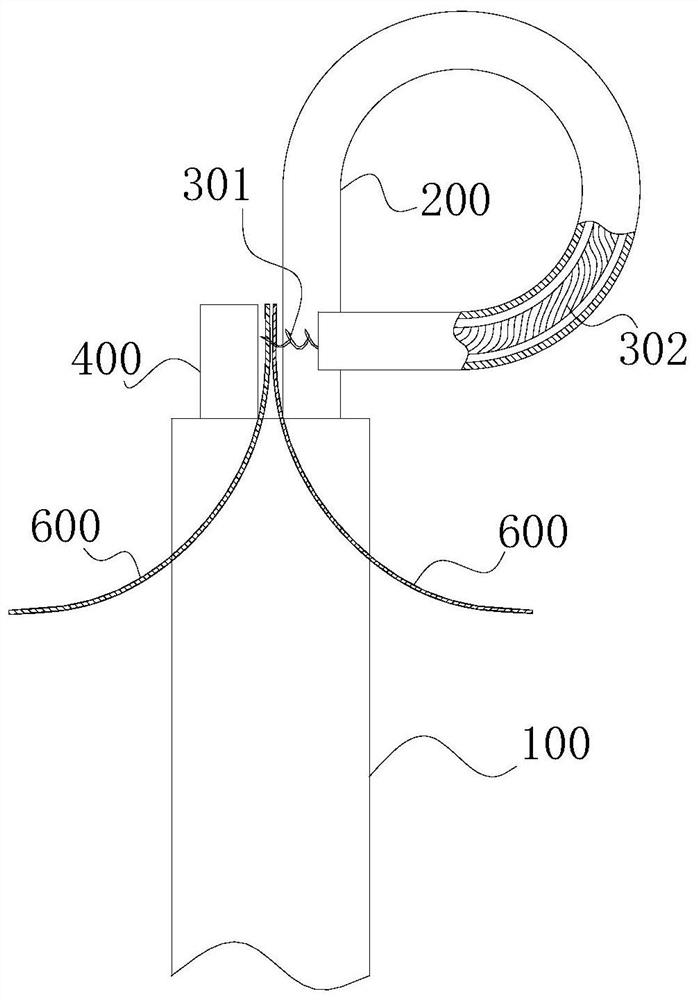

The invention discloses a curvature adjusting mechanism of a curved-surface displayer. The curvature adjusting mechanism comprises an arc-shaped retainer having first curvature, a flexible camber beam having second curvature and adjusting parts, wherein the camber beam is used for attaching to the back side of a display panel, the first curvature is smaller than the second curvature, the middle of the camber beam is fixed to the retainer, one adjusting part is arranged on two sides of the retainer in the length direction respectively, the adjusting parts are clamped between the camber beam and the retainer, and the retainer is kept movable in the length direction so as to change the curvature of the camber beam. The invention also discloses the curved-surface displayer. Due to the fact that the camber beam of the curvature adjusting mechanism attaches to and is fixed to the back side of the display panel, it is kept that the curvature of the retainer is smaller than that of the camber beam, the middle of the camber beam is fixed to the retainer, the curvature of the camber beam can be adjusted only by changing the clamping positions of the adjusting parts between the camber beam and the retainer, curvature adjustment of the display panel is achieved and can be performed in a certain range, and the demand for the best display experience of a consumer is met.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

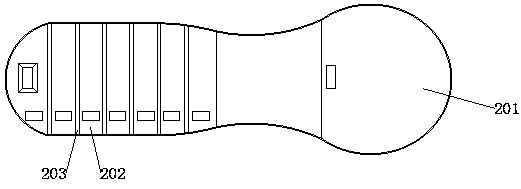

Physiotherapy waist protector

InactiveCN109223275AMagnetic therapy is effectivePromote circulationElectrotherapyMedical devicesWaist CircumferencesEngineering

The invention discloses a physiotherapy waist protector. A technical scheme of that medical device comprise a connecting belt, a first waistband, a second waistband, a small back plate, a large back plate, a first waistband and a second waistband on both sides of the connected belt, the front side of the connecting belt is closely adhered to the back side of the small back plate, the front side ofthe small back plate is closely adhered to the back side of the large back plate, and the large back plate is directly in front of the connecting belt. The physiotherapy waist protection adopts the waist protection, the ice pad and the magnetic therapy sticking in one body, effectively nursing the waist of the user, at the same time, the magnetic therapy is carried out on the user, thereby activating the energy of the human body cells and promoting the blood circulation of the human body; The invention adopts a fixing ring, a pulling ring and a tie strap to effectively adjust the curvature ofthe connecting strap, so that the waist protector is close to the body direction, the stability of the waist protector is ensured, and the waist protector is adapted to be used by users with different waist circumference; The invention adopts the combination of the waist line sensing device and the waist bending early-warning device, and effectively achieves the early-warning function for the user.

Owner:厦门杰斯医疗器械有限公司

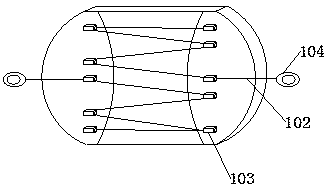

Cable bending fixing structure

InactiveCN106877228ACurvature adjustmentCable installation apparatusElectric power transmissionScrew thread

The invention relates to the technical field of electric power transmission, in particular to a cable bending fixing structure. The fixing structure comprises a fixed shaft. Multiple limiting holes are arranged in the upper end of a first moving arm and the upper end of a second moving arm. Each of the first moving arm and the second moving arm is sleeved in a sleeve. Connection lugs are arranged on the sleeves. A support rod is movably connected between the connection lugs. Upper ends of the sleeves are in threaded connection with fixing screw rods which are in threaded connection with the limiting holes. End parts of the first moving arm and the second moving arm are movably connected with two symmetrically arranged clamp plates. End parts of the clamp parts are connected with connection plates. A locking screw is connected between the connection plates. According to the invention, bending degree of a cable can be adjusted according to working tasks; use range of the fixing structure is allowed to be quite large; and the fixing structure is suitable for working under all kinds of the installation tasks.

Owner:CHENGDU FEIHANG PEIPENG TECH CO LTD

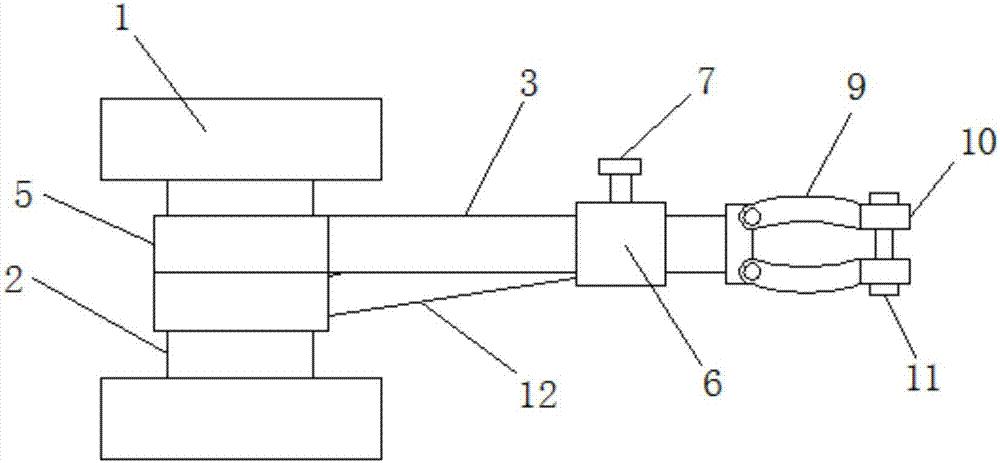

Curvature adjustment structure of curved liquid crystal display

ActiveCN103941456BCurvature adjustmentCurvature is easily adjustableNon-linear opticsLiquid-crystal displayEngineering

A curvature adjustment structure for a curved liquid crystal display, comprising: a back plate (1), at least one threaded stud (3) fixedly installed on the back plate (1), a support (5), of which two ends are against the back plate (1), that corresponds to the threaded stud (3), and an adjustment nut (7) that works in conjunction with the thread of the threaded stud (3), the threaded stud (3) penetrating the support (5) and working in conjunction with the adjustment nut (7). By rotating the adjustment nut (7), the support (5) is compressed or relaxed. The back plate (1) is compressed or relaxed by means of the support (5), thereby enabling the curvature adjustment of the back plate (1). The curvature of the curved liquid crystal display can be thus conveniently adjusted, and the product is made more attractive in the market. Additionally, the structure is simple and easy to implement.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

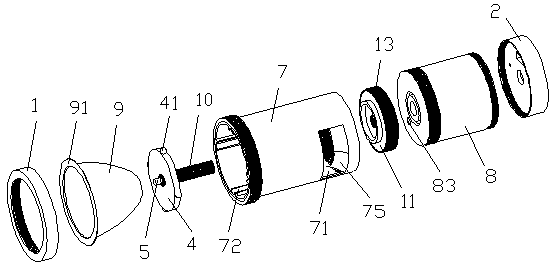

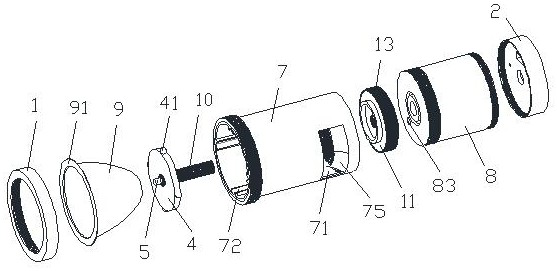

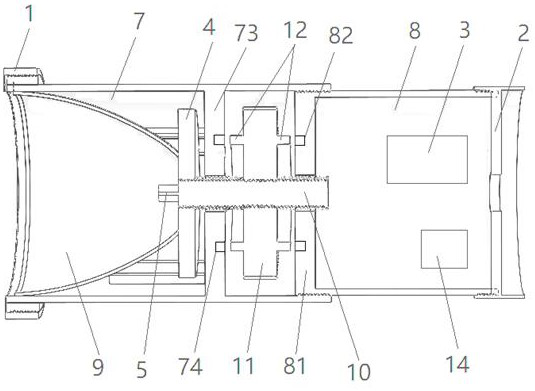

Adjustable focusing type illumination lamp based on curvature adjustment of light gathering bowl

ActiveCN110762407AExpand the scope ofEasy to adjustElectric circuit arrangementsProtective devices for lightingEngineeringOptics

The invention discloses an adjustable focusing type illumination lamp based on curvature adjustment of a light gathering bowl; an upper lamp cylinder and a lower lamp cylinder of the illuminating lampare in threaded connection; a strip-shaped side hole is formed in the side wall of the upper lamp cylinder; a lead screw is arranged in the center of the bottom surface of a lamp stand; sliding chutes are formed in the inner wall of the upper lamp cylinder at intervals; the circumferential surface of the lamp stand is provided with protrusions at intervals; the lamp stand is arranged in the innercavity of the upper lamp cylinder and the protrusions are located in the sliding chutes; a focusing disc is screwed on the lead screw and is located at the position of the strip-shaped side hole; a lamp bead is arranged in the center of the top surface of the lamp stand; the bottom end of the elastic deformable light gathering bowl is connected with the top surface of the lamp stand and the lampbead is located in the center; the top surface of the elastic deformable light gathering bowl is provided with a flanging; the lampshade is connected with the top surface of the upper lamp cylinder through threads and the flanging is fixed between the lampshade and the top surface of the upper lamp cylinder; a rear cover is connected with the bottom surface of the lower lamp cylinder through threads; and a lithium battery is arranged in the inner cavity of the lower lamp cylinder and is connected with the lamp bead through a power switch. According to the illumination lamp in the invention, curvature adjustability of the light gathering bowl is realized, the light divergence and convergence range can be continuously controlled and improved, and multiple use of the illumination lamp is realized.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

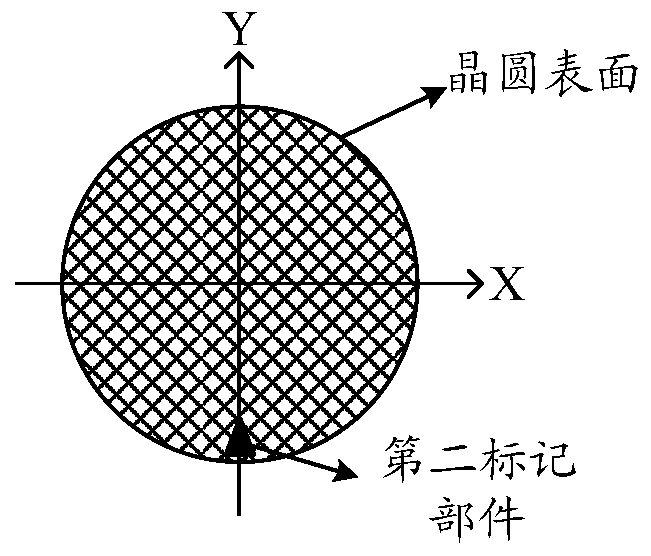

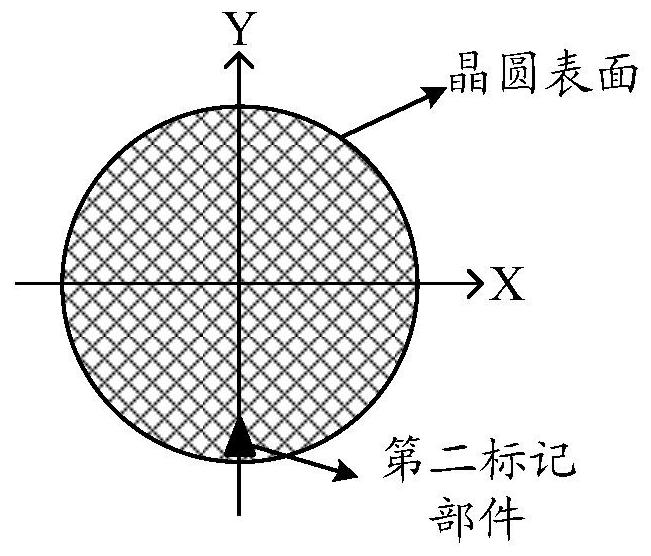

Wafer curvature adjusting device and method

ActiveCN110752171ACurvature adjustmentAchieve regulationSemiconductor/solid-state device manufacturingWafer curvatureThin membrane

The embodiment of the invention provides a wafer curvature adjusting device and method. When a film deposited on a wafer arranged on a fixing body of the wafer curvature adjusting device is etched, the etching thickness of the film deposited on the wafer in the first direction is adjusted by heating a heating component of the wafer curvature adjusting device so as to adjust the curvature of the wafer in the first direction; and the heating component is arranged on the fixing body. Therefore, the adjustment of the curvature of the wafer in the specific direction can be realized.

Owner:YANGTZE MEMORY TECH CO LTD

Submarine cable bending protection system and device

ActiveCN113258525APrecise positioningPrevent slippingCable arrangements between relatively-moving partsStructural engineeringMarine engineering

The invention discloses a submarine cable bending protection system and device. The system comprises a central positioning protection device and a bending protection device which are sequentially arranged, the central positioning protection device comprises a protection body, the front end of the protection body is conical, the protection body is assembled on a submarine cable, and the protection body is used for assembling the submarine cable in a tail section of a bent pipe. A positioning protection assembly A and a positioning protection assembly B are sequentially installed on the outer wall of the protection body, and the positioning protection assembly A and the positioning protection assembly B are both in abutting fit with the inner wall of the bent pipe so that the submarine cable can be maintained at the center position of the tail section of the bent pipe.According to the submarine cable bending protection system provided by the invention, the central position of the submarine cable can be positioned, and the positioning is accurate, so the submarine cable can be effectively prevented from sliding off from the bent pipe; and according to the bending protection device, bending protection on the submarine cable can be achieved, meanwhile, bending degree adjustment can be achieved, double-effect protection is achieved, the submarine cable is small in swing amplitude and high in impact resistance, and the current use requirement is met.

Owner:BEIJING SHANG XUN TECH DEV CO LTD

Cambered liquid crystal display device

InactiveCN107608110ACompact structureExtended service lifeNon-linear opticsLiquid-crystal displayEngineering

The invention relates to the technical field of display, in particular to a cambered liquid crystal display device. The cambered liquid crystal display device comprises a base plate, a display screen,a cylinder fixing base, a telescopic cylinder, a support rod, a connecting block and a blocking column; pushing force is applied to the two ends of the display screen through the telescopic cylinder,under the action of the blocking column, the two ends of the display screen generate deformation forwards, and then curvature adjustment is achieved, and the visual experience is improved.

Owner:HEFEI HUIKE JINYANG TECH

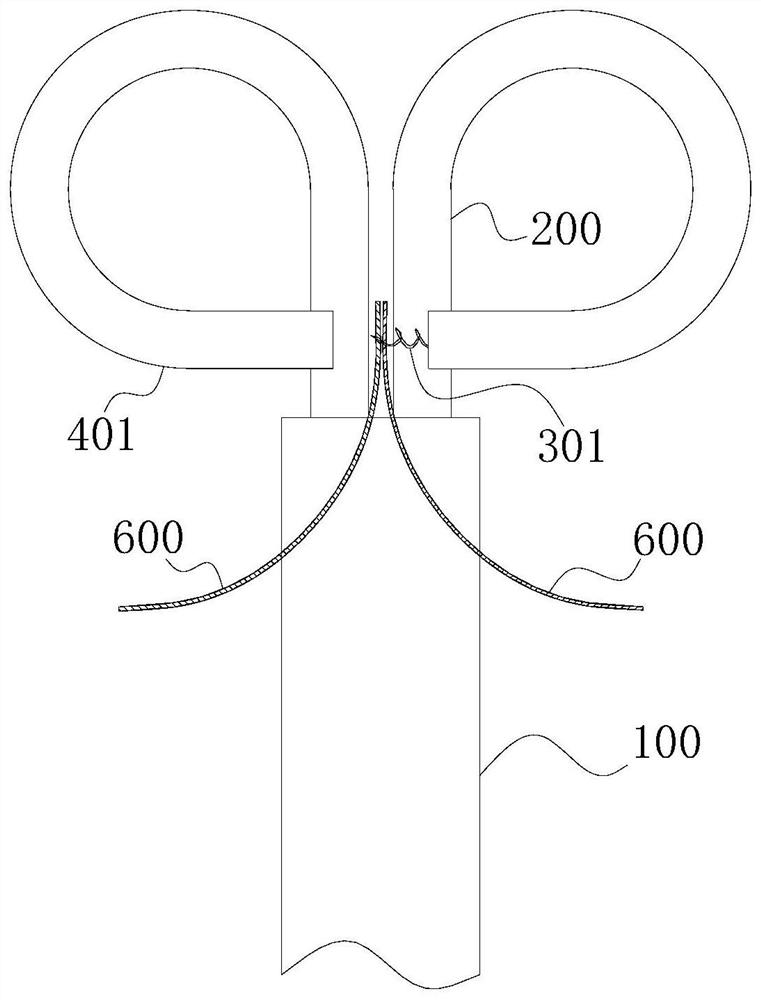

Mitral valve repair system

PendingCN111772883AInhibit sheddingHigh torqueSurgical needlesAnnuloplasty ringsEngineeringApparatus instruments

Owner:石家庄帝中医疗器械科技有限公司

Wafer curvature adjustment device and method

ActiveCN110752171BCurvature adjustmentAchieve regulationSemiconductor/solid-state device manufacturingWafer curvatureThin membrane

Embodiments of the present invention provide an apparatus and method for adjusting the curvature of a wafer. When etching the thin film deposited on the wafer disposed on the fixed body of the circular curvature adjusting device, the thin film deposited on the wafer is adjusted by heating the heating part of the wafer curvature adjusting device in the first The etching thickness in the direction is used to adjust the curvature of the wafer in the first direction; the heating component is arranged on the fixed body. In this way, the curvature of the wafer in a specific direction can be adjusted.

Owner:YANGTZE MEMORY TECH CO LTD

A submarine cable bending protection system

ActiveCN113258525BBend protection achievedPrecise positioningCable arrangements between relatively-moving partsMarine engineeringStructural engineering

The invention discloses a submarine cable bending protection system, which comprises a center positioning protection device and a protection device arranged in sequence. The center positioning protection device includes a protection body whose front end is tapered. When the submarine cable is assembled in the tail section of the curved tube, the outer wall of the protection body is sequentially equipped with A positioning protection component and B positioning protection component. Maintained at the center position of the tail section of the curved tube, the submarine cable bending protection system proposed by the present invention can realize the positioning of the center position of the submarine cable, the positioning is accurate, and can effectively prevent the submarine cable from slipping from the curved pipe. The bending protection device proposed by the present invention can The bending protection of the submarine cable can be realized, and at the same time, the adjustment of the degree of bending can be realized, and the double-effect protection can be realized, so that the swing range of the submarine cable is small, and the impact resistance is strong, which meets the current use requirements.

Owner:BEIJING SHANG XUN TECH DEV CO LTD

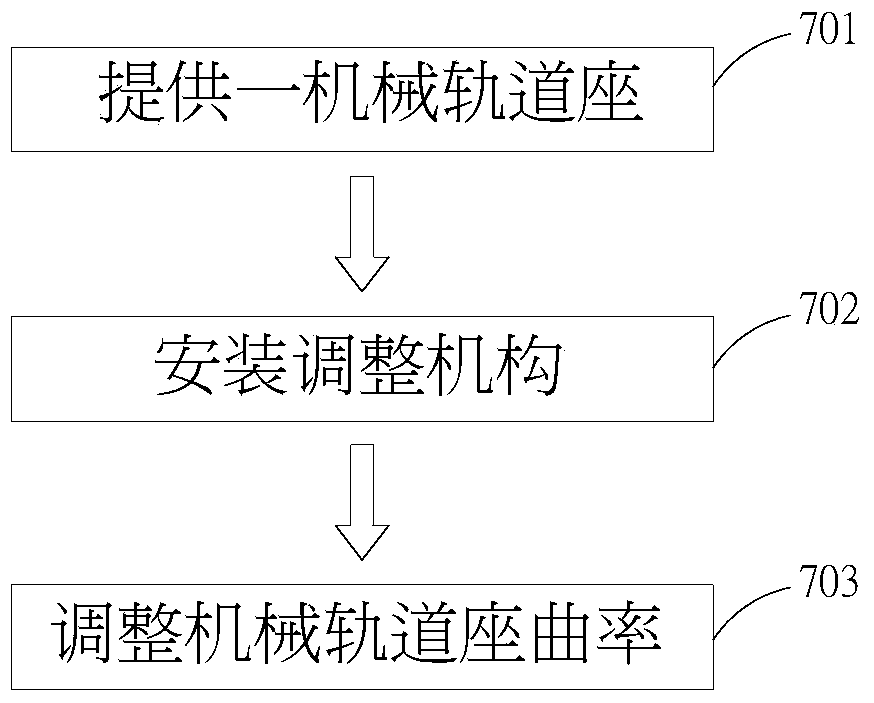

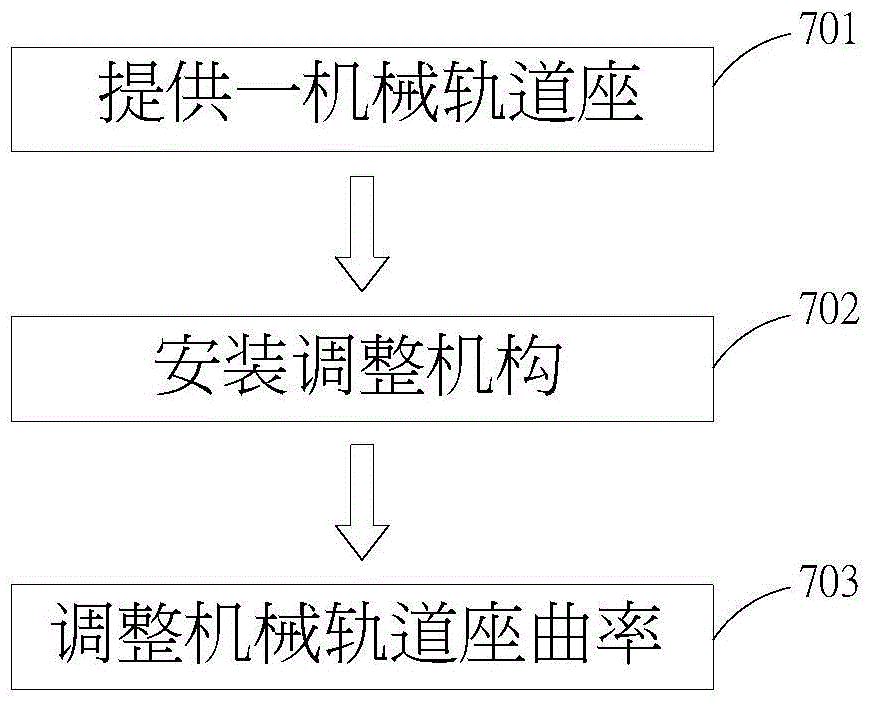

Manufacturing method of supporting mechanism of curved surface liquid crystal display device

InactiveCN107859821ACompact structureExtended service lifeStands/trestlesManufacturing technologyLiquid-crystal display

The invention relates to the technical field of display, particularly to a manufacturing method of a supporting mechanism of a curved surface liquid crystal display device. The manufacturing method comprises the steps of (1) structure and respective processing: preparing telescopic cylinders according to the prior art, forging cylinder fixing seats through a carbon steel material, and casting first supporting parts, second supporting parts and connecting blocks through a metal material; (2) pretreatment: putting the first supporting parts, the second supporting parts and the connecting blocksinto a tank solution to be pretreated, and after pretreatment, taking out, cleaning and drying the first supporting parts, the second supporting parts and the connecting blocks; and (3) follow-up assembly forming: firstly, assembling the first supporting parts, the second supporting parts and the connecting blocks together, then, mounting and fixing the first supporting parts and telescopic rods of the telescopic cylinders, mounting the telescopic cylinders on the cylinder fixing seats, and finally, mounting a display on the connecting blocks. According to the supporting mechanism of the curved surface liquid crystal display device and the manufacturing method thereof, the structure of the supporting mechanism is more compact through a reasonably designed manufacturing technology, and theservice life is longer.

Owner:HEFEI HUIKE JINYANG TECH

Adjustable focus illuminating lamp based on the adjustment of the curvature of the spotting bowl

ActiveCN110762407BCurvature adjustmentCurvature adjustableElectric circuit arrangementsWith electric batteriesEngineeringMechanical engineering

The invention discloses a focus-adjustable illuminating lamp based on the curvature adjustment of a concentrating bowl. The upper and lower lamp tubes of the illuminating lamp are threadedly connected, the side wall of the upper lamp tube is provided with a long side hole, and the lead screw is arranged on the bottom surface of the lamp stand. In the center, the inner wall of the upper lamp tube is spaced with a chute, the circumferential surface of the lamp table is provided with protrusions at intervals, the lamp table is arranged in the inner cavity of the upper lamp tube and the protrusion is located in the chute, the focusing disc is screwed on the lead screw and located in the side hole of the long strip Position, the lamp bead is set at the center of the top surface of the lampstand, the bottom end of the elastically deformable concentrating bowl is connected to the top surface of the lampstand and the lamp bead is located in the center, the top surface of the elastically deformable concentrating bowl is provided with a flange, and the lampshade is connected to the top of the lamp tube by threads and the flange is fixed between the lampshade and the top surface of the upper lamp canister, the back cover and the bottom surface of the lower lamp canister are connected by threads, and the lithium battery is arranged in the inner cavity of the lower lamp canister and is connected to the lamp beads through a power switch. The illuminating lamp realizes that the curvature of the concentrating bowl can be adjusted, can continuously control and improve the range of light divergence and convergence, and realize the multiple utilization of the illuminating lamp.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

An all-in-one machine for bending and cutting circles

ActiveCN108145439BCooperate scientifically and reasonablyStable jobOther manufacturing equipments/toolsElectric machineryEngineering

The invention discloses a flanging and circle-cutting all-in-one machine comprising a machine station, and a centering component, a controllable pitch component and a shearing component which are arranged on the machine station. The shearing component comprises a gear motor, an upper cutter shaft and a lower cutter shaft, and the upper cutter shaft and the lower cutter shaft are arranged in parallel, and driven by the gear motor to rotate; the rotation directions of the upper cutter shaft and the lower cutter shaft are opposite, and the end of the upper cutter shaft is provided with a first squeezing roller and a first cutter; the circumference of the first squeezing roller is sunken inward, and the end of the lower cutter shaft is provided with a second squeezing roller and a second cutter; the circumference of the second squeezing roller protrudes outward, and the position of the first squeezing roller is corresponding to the position of the second squeezing roller; and the positionof the first cutter is corresponding to the position of the second cutter. Compared with the prior art, the all-in-one machine disclosed by the invention has the advantages of stable working performance and high machining precision by arrangement of relevant structures.

Owner:湖南省辰波建设有限公司

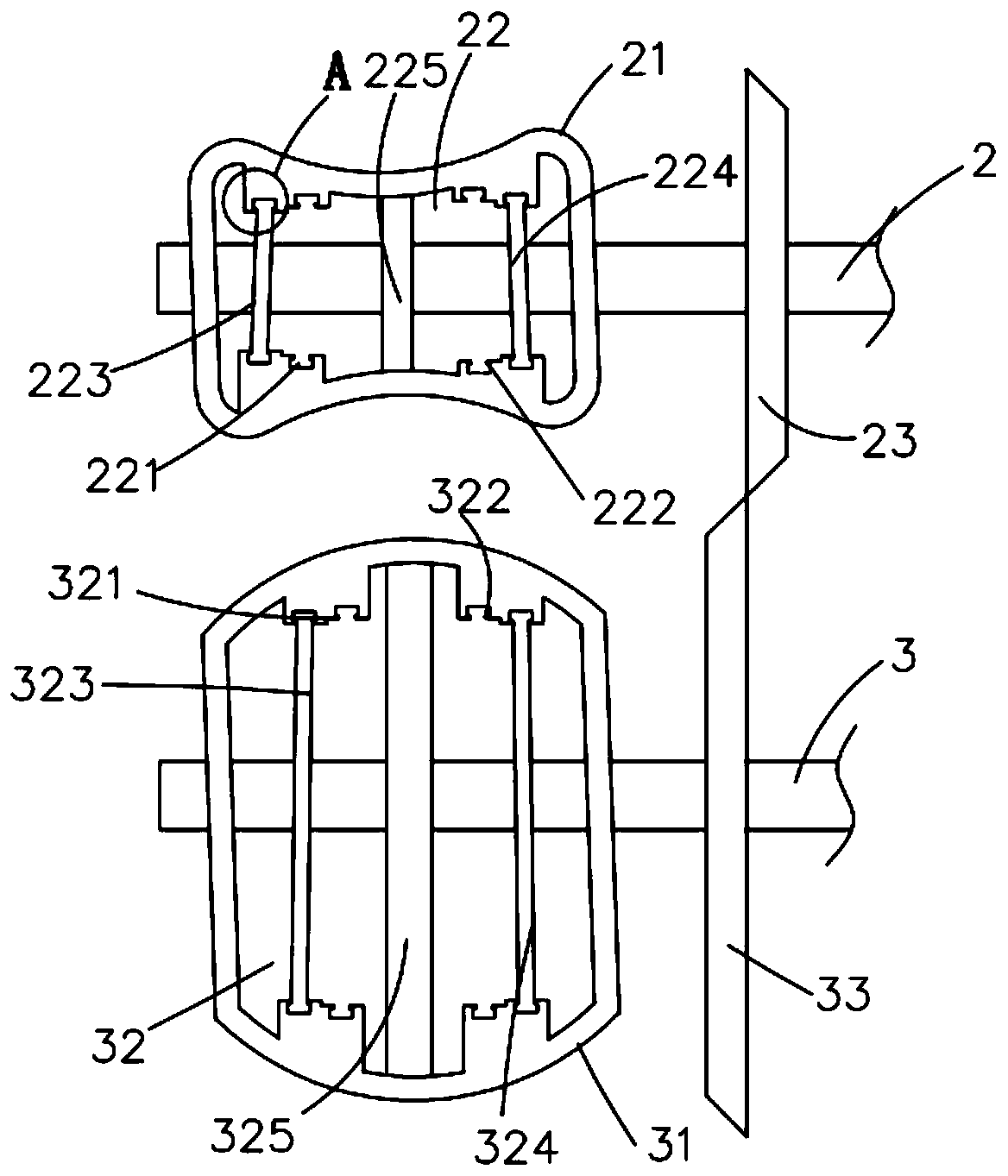

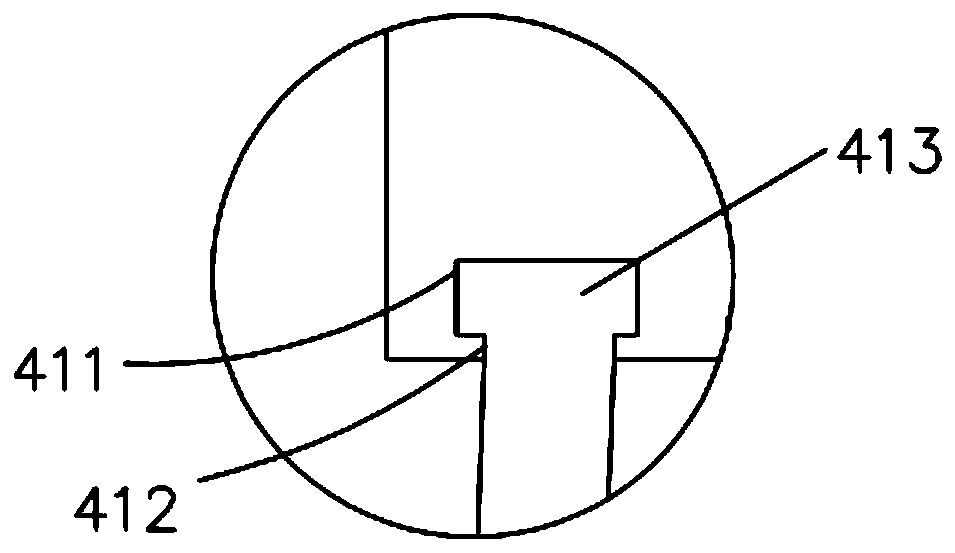

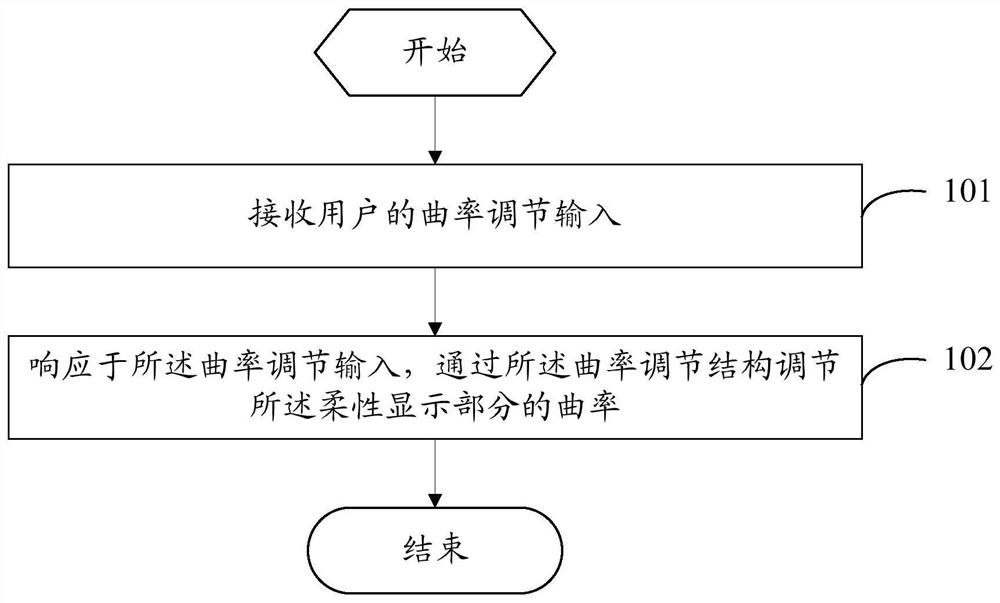

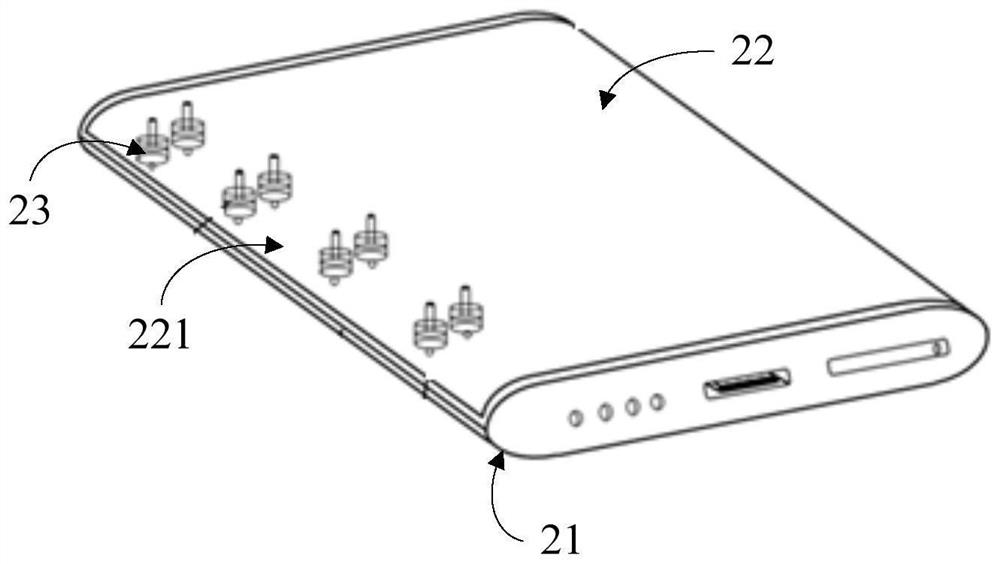

Control method of electronic equipment and electronic equipment

InactiveCN112767837ACurvature adjustmentImprove the display effectIdentification meansComputer hardwareEngineering

The invention discloses a control method of electronic equipment and the electronic equipment and belongs to the technical field of communication. The electronic equipment comprises a display screen and a curvature adjusting structure, wherein at least one part of the display screen is a flexible display part, the curvature of the flexible display part is adjustable, the curvature adjusting structure is arranged below the display screen, and the curvature adjusting structure is arranged corresponding to the flexible display part. The method comprises the following steps of receiving curvature adjustment input of a user; in response to the curvature adjustment input, a curvature of the flexible display portion being adjusted by the curvature adjustment structure. The method is advantaged in that viewing difficulty of the display content of the flexible display part can be reduced.

Owner:VIVO MOBILE COMM CO LTD

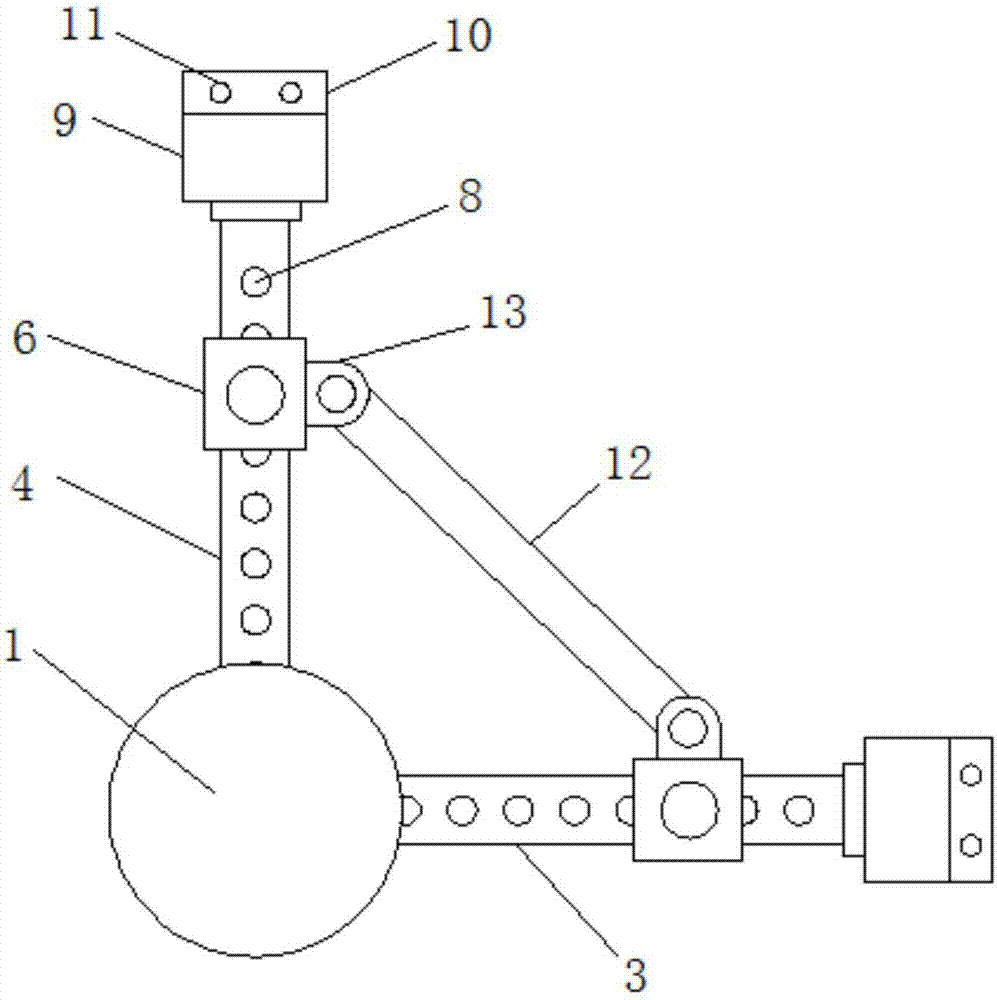

A waist iron forming machine tool

The invention discloses a forming machine tool of waist iron. The forming machine tool comprises a machine base, and an operation table is arranged on the machine base; a sliding groove is formed in the operation table; at least one locating pillar and at least one operation pillar are arranged in the sliding groove in a sliding manner; the locating pillars stretch out of the operation table through the sliding groove; cross pillars are vertically and fixedly arranged at the bottom tail ends of the locating pillars; two clamps are hinged to each cross pillar; the two clamps are arranged on thetwo sides of the locating pillar separately; bulges of the tops of the clamps are hinged to the cross beams through bolts; compression springs are arranged between the bulges and the locating pillars; the parts, stretching out of the operation table, of the locating pillars are provided with screwing round discs; and the operation pillars stretch out of the operation table through the sliding groove. According to the forming machine tool of waist iron provided by the invention, the bending degree of waist iron can be well adjusted, and arrangement and control of the bending degree during waist iron forming are greatly facilitated.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

Curved Surface Display and Its Curvature Adjustment Mechanism

ActiveCN107464504BCurvature adjustmentMeet the needs of the display experienceIdentification meansDisplay deviceEngineering

The invention discloses a curvature adjusting mechanism of a curved-surface displayer. The curvature adjusting mechanism comprises an arc-shaped retainer having first curvature, a flexible camber beam having second curvature and adjusting parts, wherein the camber beam is used for attaching to the back side of a display panel, the first curvature is smaller than the second curvature, the middle of the camber beam is fixed to the retainer, one adjusting part is arranged on two sides of the retainer in the length direction respectively, the adjusting parts are clamped between the camber beam and the retainer, and the retainer is kept movable in the length direction so as to change the curvature of the camber beam. The invention also discloses the curved-surface displayer. Due to the fact that the camber beam of the curvature adjusting mechanism attaches to and is fixed to the back side of the display panel, it is kept that the curvature of the retainer is smaller than that of the camber beam, the middle of the camber beam is fixed to the retainer, the curvature of the camber beam can be adjusted only by changing the clamping positions of the adjusting parts between the camber beam and the retainer, curvature adjustment of the display panel is achieved and can be performed in a certain range, and the demand for the best display experience of a consumer is met.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

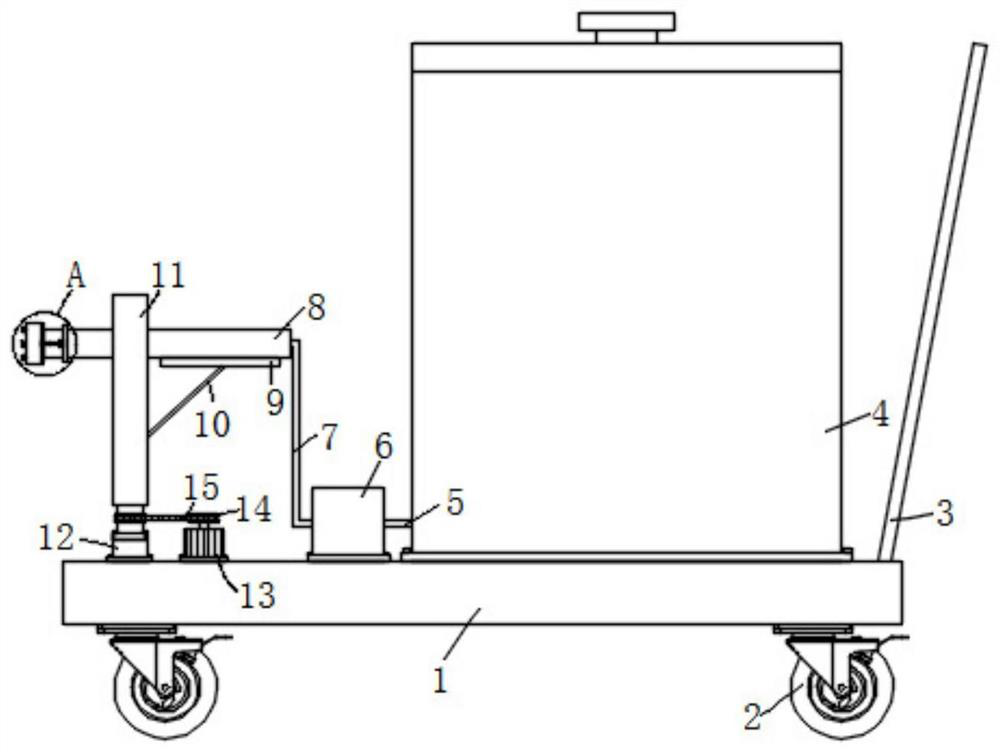

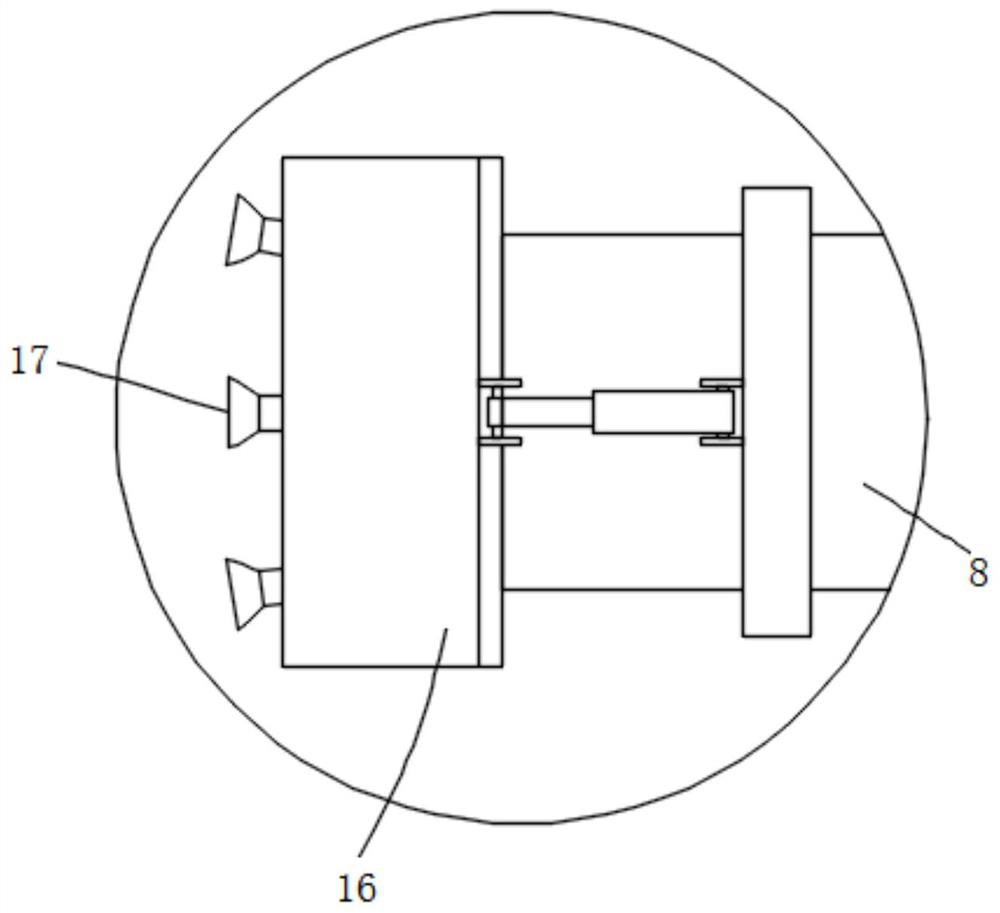

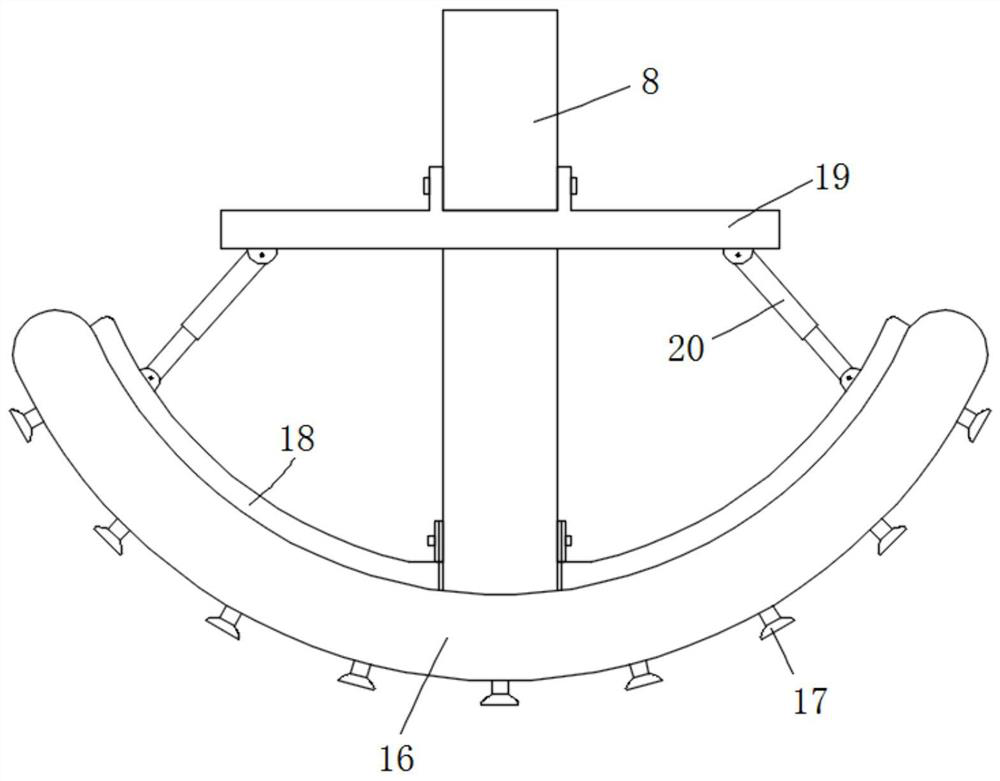

Water spraying dust settling device for civil construction site

PendingCN112127312AExpand the scope of water spraying and dust suppressionCurvature adjustmentRoad cleaningBuilding material handlingEnvironmental resource managementMechanical engineering

The invention discloses a water spraying dust settling device for a civil construction site, and belongs to the technical field of civil construction. The water spraying dust settling device comprisesa bottom plate, wherein a water tank and a pump body are fixedly installed at the top of the bottom plate, a water outlet pipe is fixedly installed at a water outlet of the water tank, the end, awayfrom the water tank, of the water outlet pipe is connected with the water inlet end of the pump body, a rotating part is fixedly installed at the top of the bottom plate, a fixing frame is installed at the top of the rotating part, a first movable groove and a second movable groove are formed in the fixing frame, and the second movable groove is located above the first movable groove. According tothe water spraying dust settling device, an arc-shaped pipe is used, so that water spraying heads can spray water around to settle dust, a water spraying area can be in a fan shape, and the water spraying dust settling range is enlarged; the curvature of the arc-shaped pipe can be adjusted through arranged electric telescopic rods, and small-range water spraying dust settling can be achieved; andmulti-level water spraying can be achieved through three-row type water spraying head arrangement, area omission is avoided, and the water spraying dust settling effect is ensured.

Owner:CSCEC STRAIT CONSTR & DEV

Finishing method of titanium alloy seamless pipe

The invention relates to a titanium alloy seamless pipe finishing method, and belongs to the technical field of titanium alloy seamless pipe. The invention aims to provide a method for finishing titanium alloy seamless pipe. The method comprises the following steps in sequence: step a, heat treatment: filling a titanium alloy seamless pipe with aluminum silicate fibers, and then carrying out a heat treatment, wherein the heat treatment temperature is 700 to 930 DEG C, and the residual oxygen content in the heat treatment furnace is controlled at 3% or less; step b, primary straightening: straightening the titanium alloy seamless pipe at a temperature of 500 to 600 DEG C for the first time, and then cooling to the room temperature; step c, secondary straightening: straightening the titanium alloy seamless pipe at a room temperature for a second time, and then washing the pipe with acid so as to obtain the titanium alloy seamless pipe. The provided finishing method can adjust the flexibility of a titanium alloy seamless pipe, at the same time the oxide scale on the surface of the titanium alloy seamless pipe is removed, the technology is simplified, the titanium metal consumption is reduced, and the effect on removing the oxide scale on the inner / outer surfaces of a titanium alloy seamless pipe is better.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

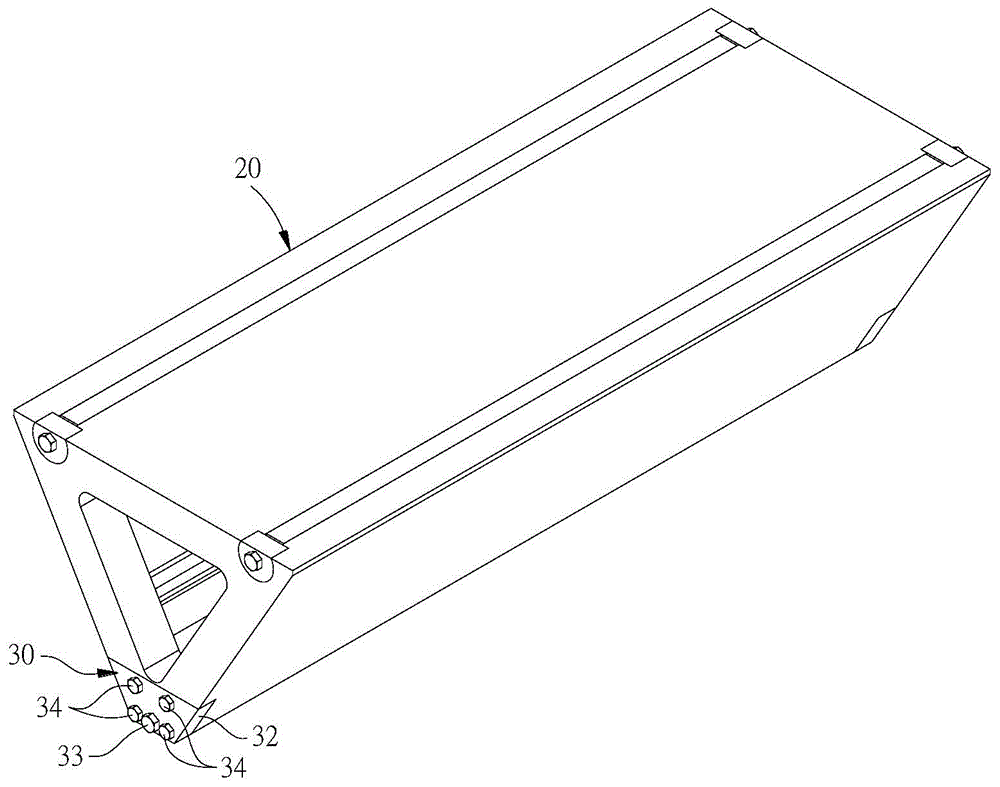

Curvature adjusting device, display device and display device jig

PendingCN114429732AAdjust the curvature of the display surfaceSimple structureStands/trestlesIdentification meansRotational axisDisplay device

The invention relates to the field of display, and provides a curvature adjusting device, a display device and a display device jig, the curvature adjusting device is used for adjusting the curvature of a display surface of a flexible display substrate, the curvature adjusting device comprises a rotating structure capable of rotating around a first rotating axis, and the rotating structure is connected with the flexible display substrate and has a curve profile; the curved contour is used for supporting the flexible display substrate, and when the rotating structure rotates around the first rotating axis, the flexible display substrate is driven to be bent by different degrees, so that the curvature of the display surface of the flexible display substrate is adjusted. By applying the flexible display substrate, the structure is simple, and the curvature of the display surface of the flexible display substrate can be adjusted under the condition that other auxiliary tools are not needed.

Owner:BOE TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com