Artificial turf bent filament and preparation method thereof

A technology of artificial turf and curly yarn, which is applied in the manufacture of rayon, conjugated synthetic polymer artificial filament, melt spinning, etc., can solve the problems of aging resistance and poor hand feeling, and achieve long service life and good aging resistance , the effect of uniform curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

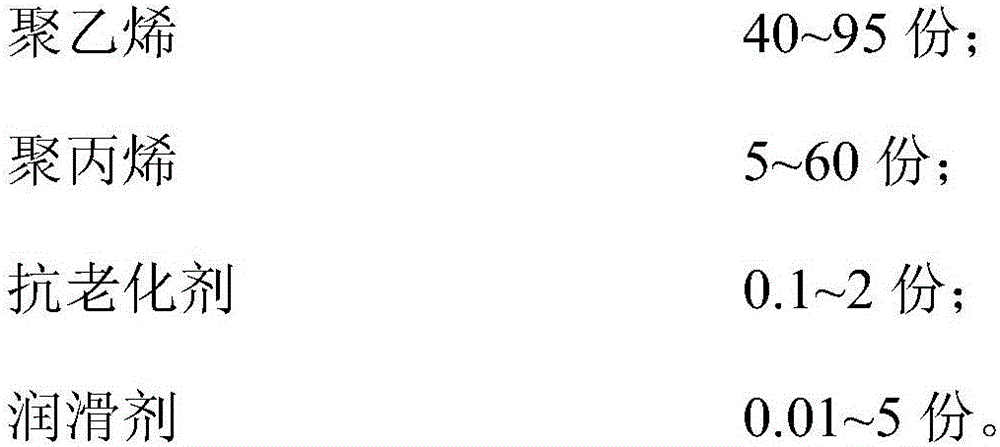

[0045] 1) getting the raw materials ready: take the following raw materials by weight,

[0046]

[0047] The raw materials are mixed and melted, and the melting temperature is 220°C;

[0048] 2) Extrusion: Extrude the melted raw material in step 1) under the condition of 240°C, and the extruded raw material enters the metering pump after being filtered;

[0049] 3) forming a monofilament: the raw material obtained in step 2) is quantitatively sent into the spinning die head by a metering pump, the spinning die head ejects the monofilament, and the monofilament is introduced into the drafting machine by the traction roller; the speed of the traction roller is 10m / min;

[0050] 4) Drafting: the stretching roller in the drafting machine draws the monofilament obtained in step 3) with a draft ratio of 4 times; the speed of the stretching roller is 50m / min.

[0051] 5) Cooling: put the monofilament drawn in step 4) into a water bath, and the temperature of the water bath is 9...

Embodiment 2

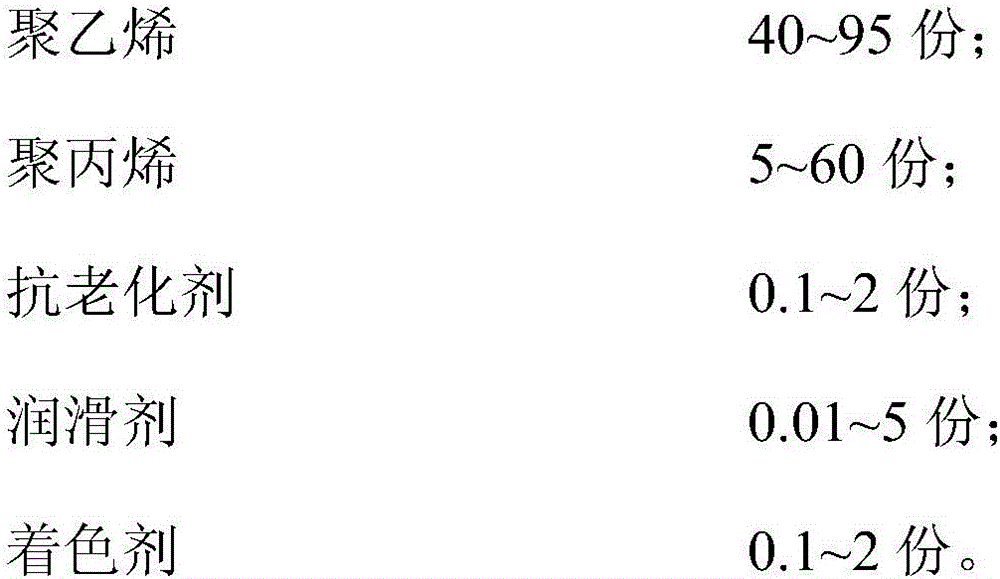

[0055] 1) getting the raw materials ready: take the following raw materials by weight,

[0056]

[0057] The raw materials are mixed and melted, and the melting temperature is 220°C;

[0058]2) Extrusion: Extrude the melted raw material in step 1) under the condition of 230°C, and the extruded raw material enters the metering pump after being filtered;

[0059] 3) forming a monofilament: the raw material obtained in step 2) is quantitatively sent into the spinning die head by a metering pump, the spinning die head ejects the monofilament, and the monofilament is introduced into the drafting machine by the traction roller; the speed of the traction roller is 10m / min;

[0060] 4) Drafting: the stretching roller in the drafting machine drafts the monofilament obtained in step 3) with a draft ratio of 5 times; the speed of the stretching roller is 60m / min.

[0061] 5) Cooling: put the monofilament drawn in step 4) into a water bath, and the temperature of the water bath is 9...

Embodiment 3

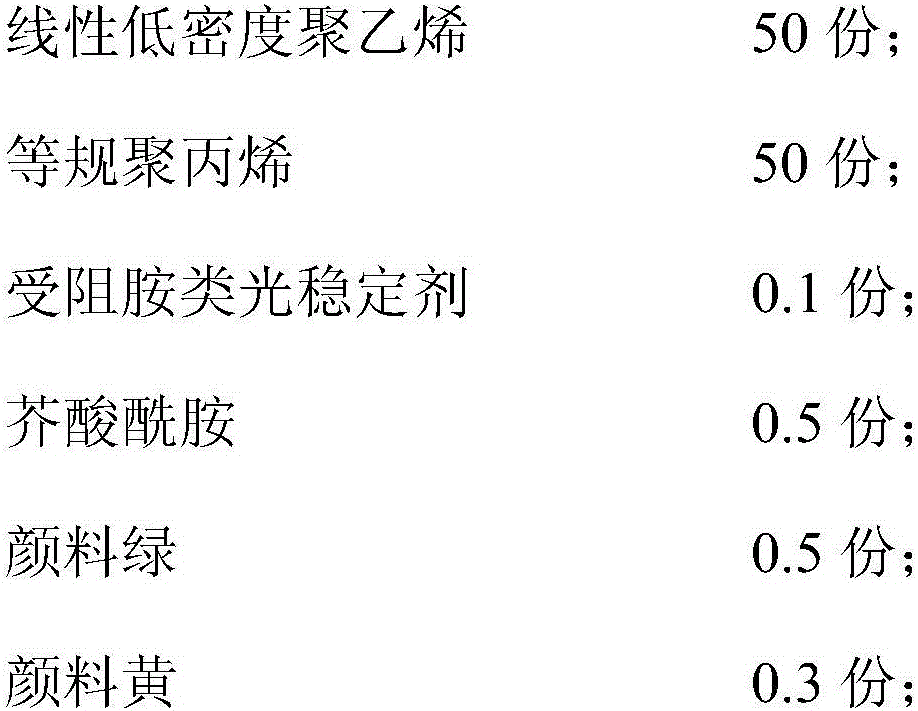

[0065] 1) getting the raw materials ready: take the following raw materials by weight,

[0066]

[0067] The raw materials are mixed and melted, and the melting temperature is 220°C;

[0068] 2) Extrusion: Extrude the melted raw material in step 1) under the condition of 235°C, and the extruded raw material enters the metering pump after being filtered;

[0069] 3) form monofilament: the raw material that step 2) is obtained is quantitatively sent into spinning die head by metering pump, monofilament is ejected by spinning die head, and monofilament is introduced drafting machine by traction roller; The speed of traction roller is 12m / min;

[0070] 4) Drafting: the stretching roller in the drafting machine drafts the monofilament obtained in step 3) with a draft ratio of 5 times; the speed of the stretching roller is 60m / min.

[0071] 5) Cooling: put the monofilament drawn in step 4) into a water bath, and the temperature of the water bath is 95°C;

[0072] 6) Preheating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com