Simple method for transforming integrated distribution box into fiber distribution box

A technology of fiber distribution box and distribution box, which is applied in fiber mechanical structure, light guide, optics, etc., can solve the problems of not meeting the actual needs of the market, increasing the operator's input cost, etc., and achieve space saving, energy saving, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

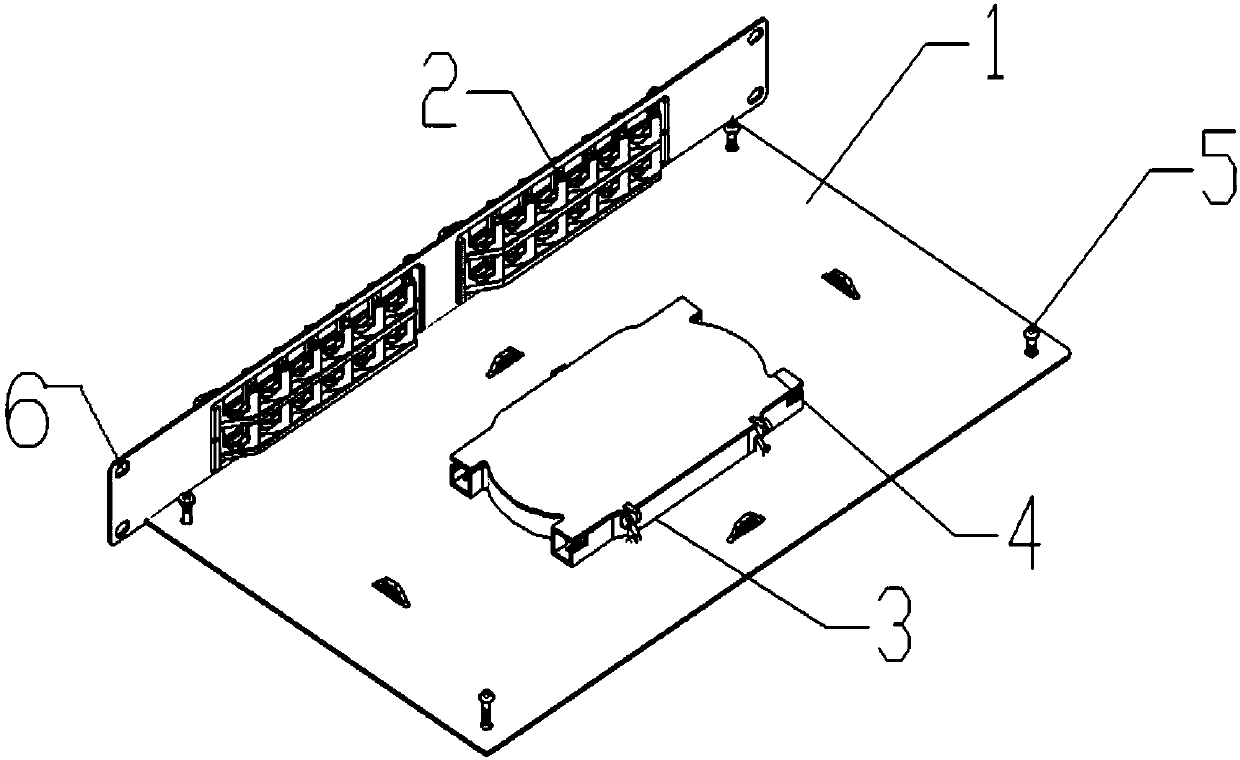

[0019] The fiber distribution box transformation assembly includes a multifunctional installation plate 1, an adapter seat plate 2 and a fiber splice tray assembly 4, the multifunctional installation plate 1 includes a bottom plate and a side plate perpendicular to the bottom plate on the side of the bottom plate, the The size of the multifunctional mounting plate 1 is suitable for a 19-inch wiring box, the height is 1U, and the side plate has a 19-inch mounting hole 6; the splice tray assembly 4 also includes a 24-core splice tray cover 3, so The splice tray assembly 4 is installed in the middle of the base plate through two self-tapping screws through the two mounting holes at the bottom and the two corresponding mounting holes on the base plate, and the adapter seat plate 2 is clamped and mounted on the base plate into the mounting slot on the side panel.

[0020] According to the embodiment of the present invention, a simple method for transforming part of the integrated d...

Embodiment 2

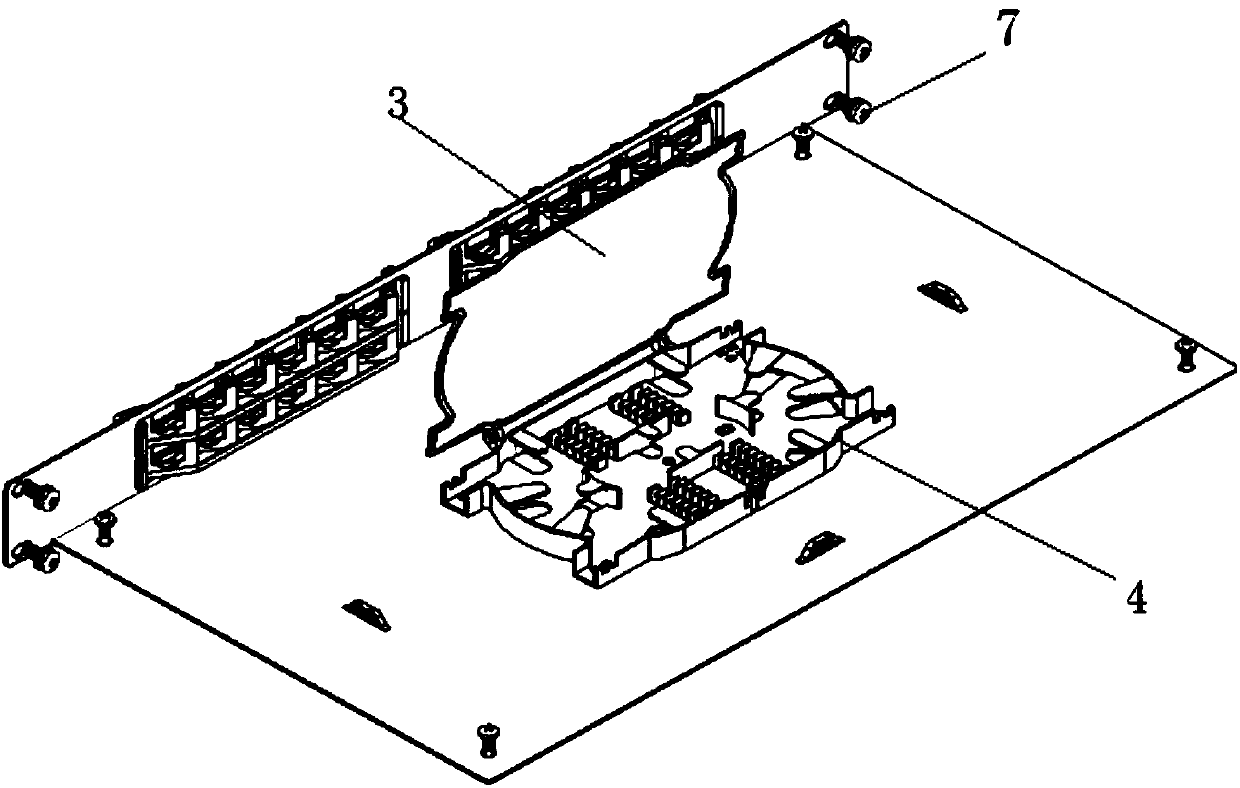

[0022] The fiber distribution box transformation assembly includes a multifunctional installation plate 1, an adapter seat plate 2 and a fiber splice tray assembly 4, the multifunctional installation plate 1 includes a bottom plate and a side plate perpendicular to the bottom plate on the side of the bottom plate, the The size of the multifunctional mounting plate 1 is suitable for a 19-inch wiring box, the height is 1U, and the side plate has a 19-inch mounting hole 6; the splice tray assembly 4 also includes a 24-core splice tray cover 3, so The splice tray assembly 4 is installed in the middle of the base plate by two dovetail groove self-tapping screws through the two mounting holes at the bottom and the two corresponding mounting holes on the base plate, and the adapter seat plate 2 is clamped and mounted on the in the mounting groove of the side panel.

[0023] According to the embodiment of the present invention, a simple method for transforming the integrated distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com