A Method for Comprehensive Evaluation of Batch Tobacco Leaf Quality

A technology of comprehensive evaluation and quality evaluation, applied in the field of comprehensive evaluation of batch tobacco leaf quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be specifically introduced below in conjunction with specific embodiments.

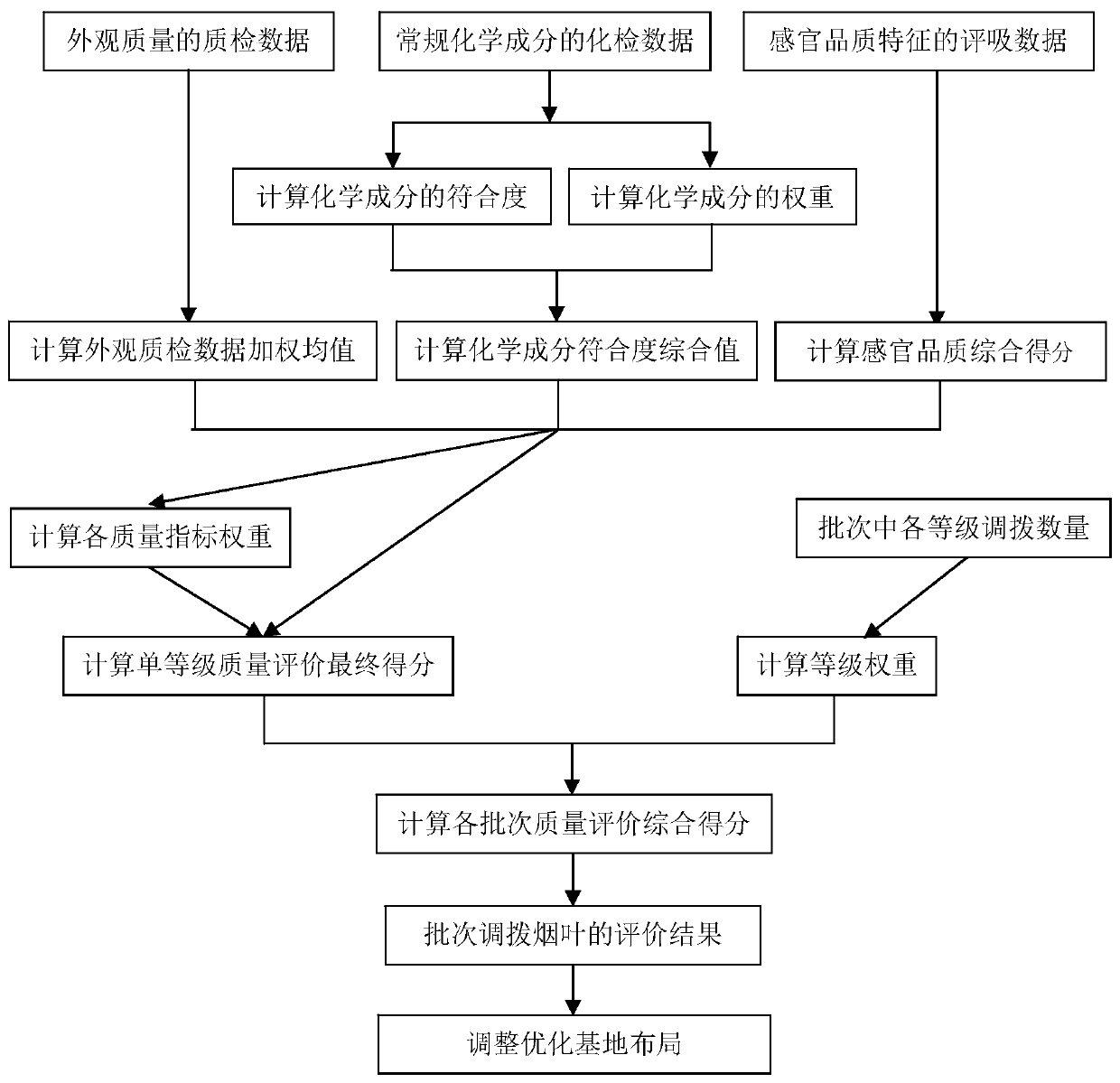

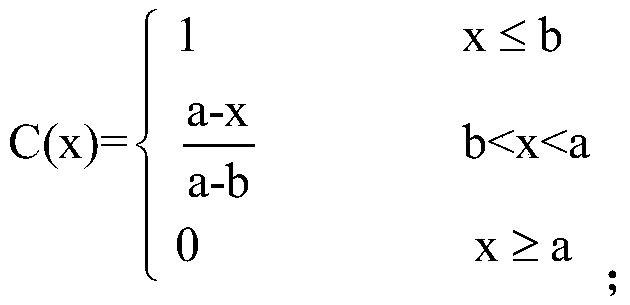

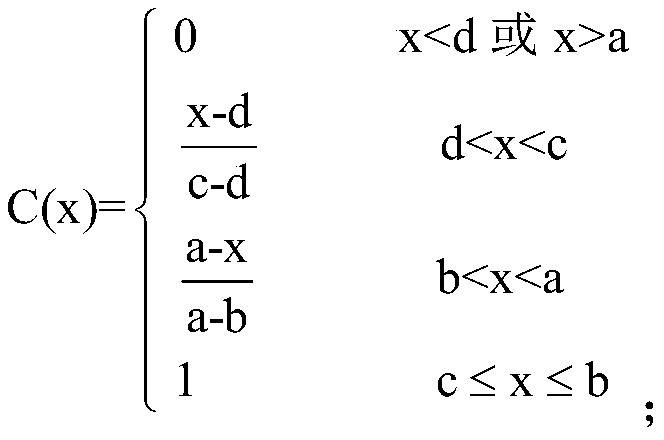

[0077] A method for comprehensive evaluation of the quality of batches of tobacco leaves, comprising: collecting raw flue-cured tobacco samples during the batch transfer process, measuring the data of appearance, chemical and sensory quality evaluation of flue-cured tobacco, and calculating each quality by constructing a coincidence function model and dimensionless processing. Finally, the final score of flue-cured tobacco quality evaluation and the grade and quantity information of batch allocation are combined to obtain the evaluation results; the flue-cured tobacco quality evaluation indexes include: flue-cured tobacco appearance quality index, conventional chemical composition index, sensory quality characteristic index; flue-cured tobacco The appearance quality index is: the weighted average value of the single-level different sample quality inspection data in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com