Bottom welding effect verification method and device for negative tab of cylindrical battery

A technology of battery negative electrode and inspection method, which is applied in the direction of cylindrical shell battery/battery, measuring device, battery assembly machine, etc., can solve problems such as battery leakage inspection, and achieve the effect of reducing unqualified products and improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

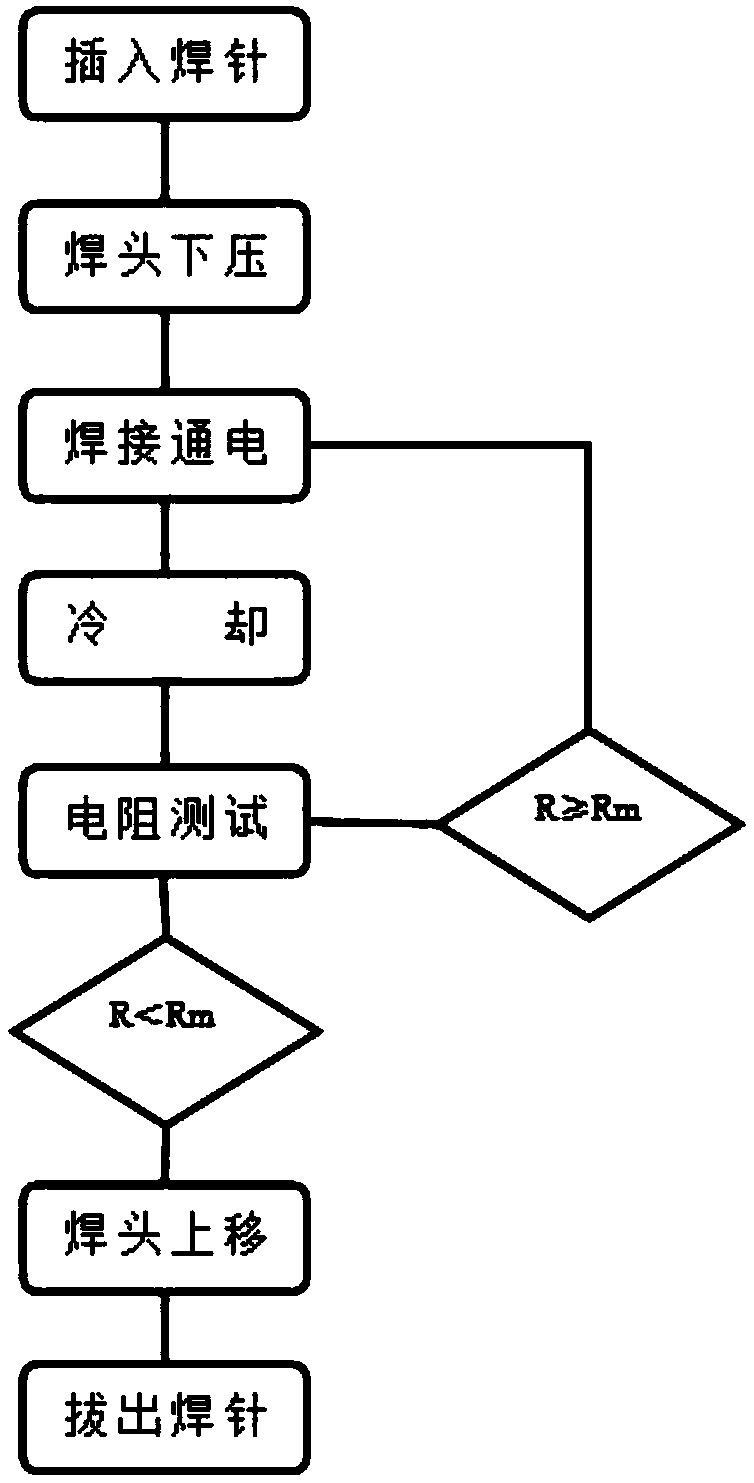

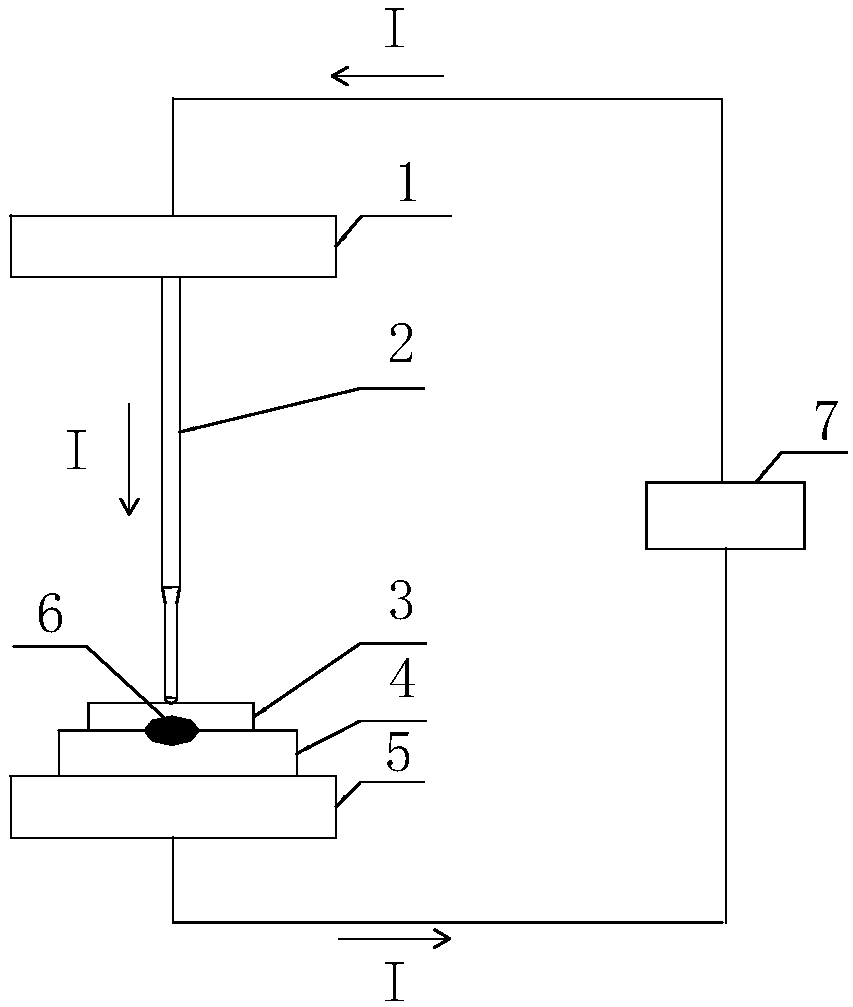

Method used

Image

Examples

specific Embodiment approach

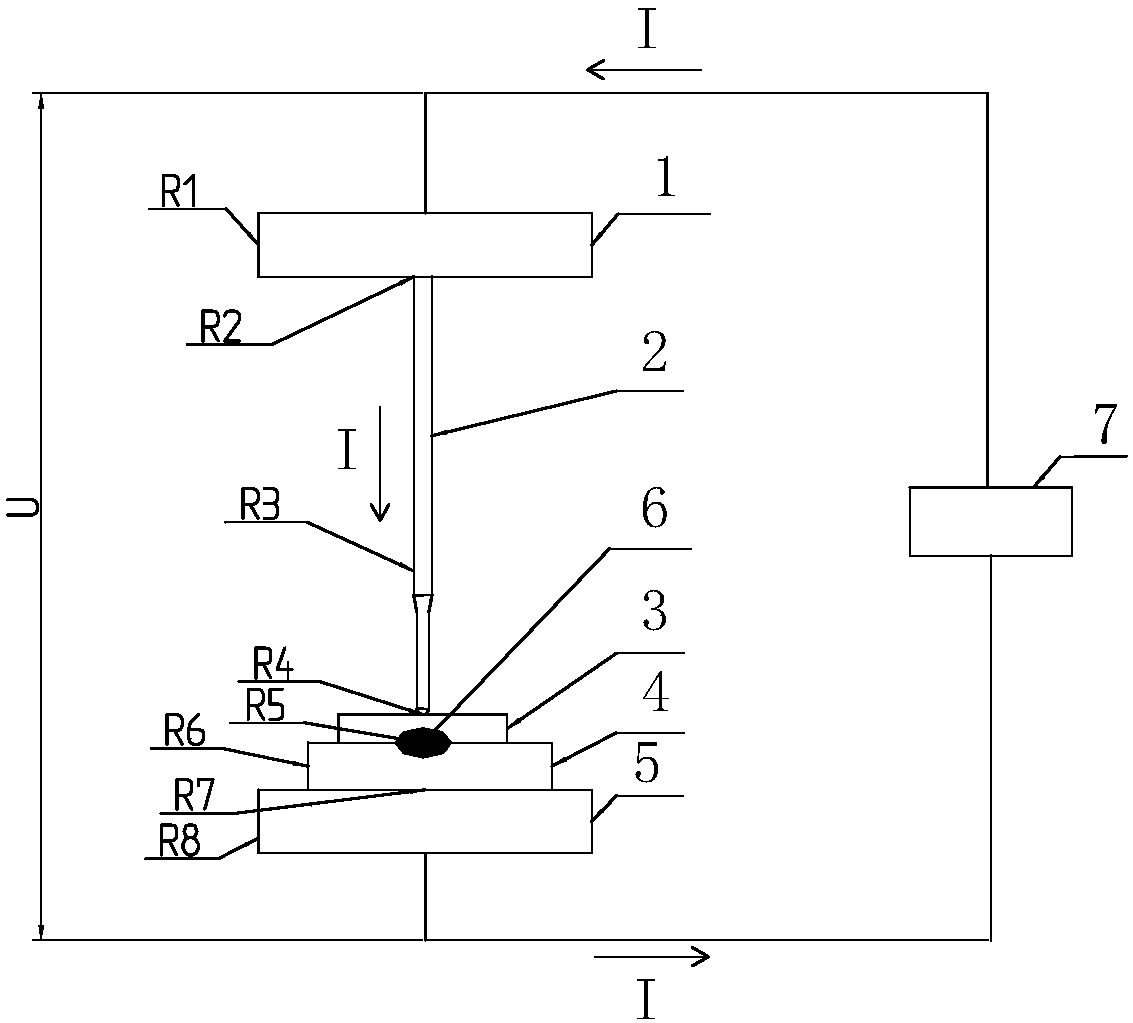

[0047] Further, see image 3 , as a specific implementation of the method for testing the welding effect of the bottom ear of the cylindrical battery negative electrode provided by the present invention, the measured resistance value R=R1+R2+R3+R4+R5+R6+R7+R8;

[0048]In the formula, R1 is the resistance of the welding head, R2 is the contact resistance between the welding needle 2 and the welding head, R3 is the resistance of the welding needle, R4 is the resistance between the welding needle 2 and the negative ear 3, R5 is the contact resistance between the negative ear 3 and the steel The resistance after the shell 4 is fused, R6 is the resistance of the steel shell, R7 is the contact resistance between the steel shell 4 and the soldering station 5, and R8 is the resistance of the soldering station;

[0049] In the formula, R1, R2, R3, R4, R6, R7, R8 are fixed values.

[0050] The method for testing the bottom welding effect of the negative pole ear of the cylindrical batt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com