Low-NO<x> efficient chain grate furnace with function of distributing air by area in width direction of grate

A chain furnace and grate technology, applied in the field of chain furnaces, can solve the problems of poor burnout and coal piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

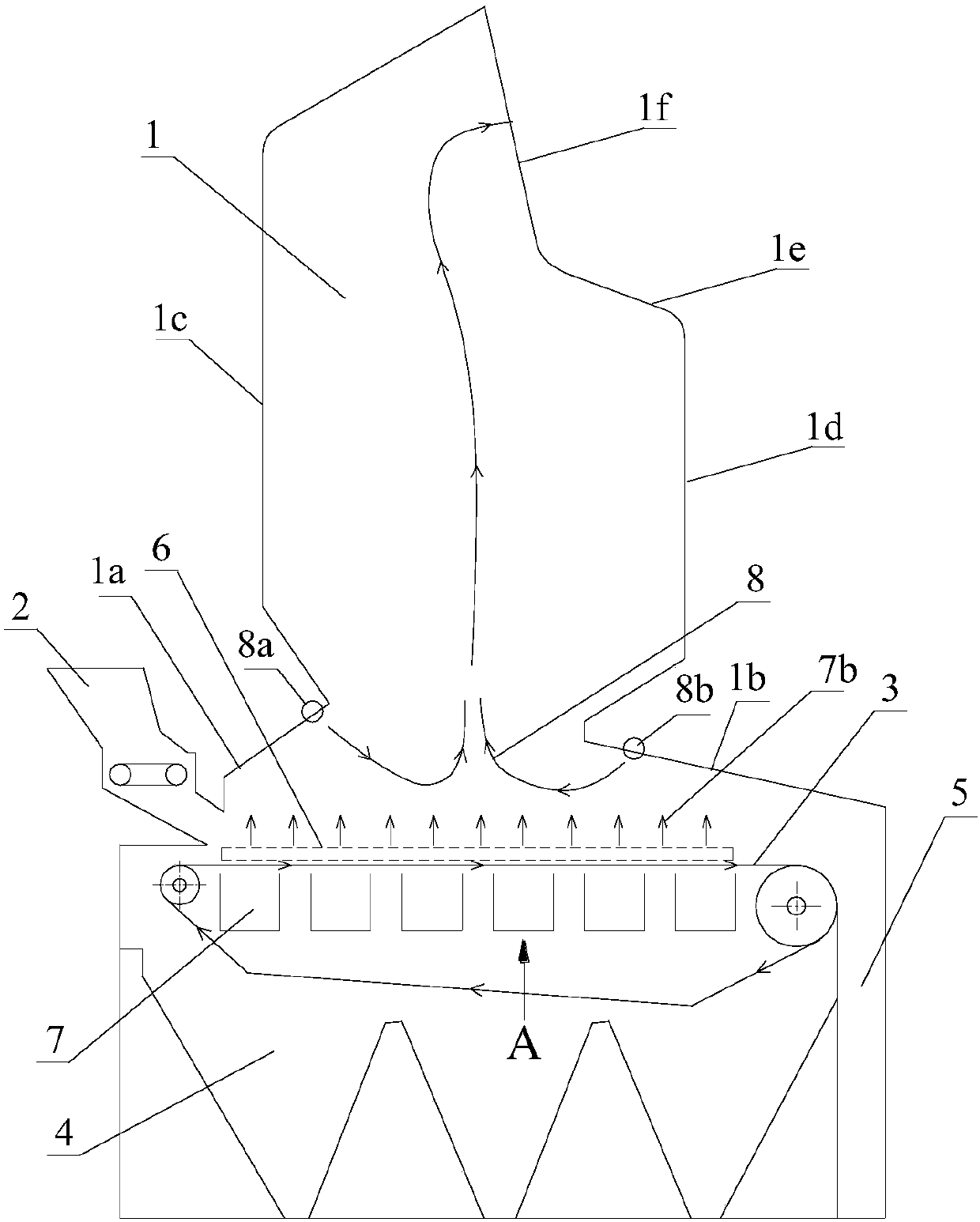

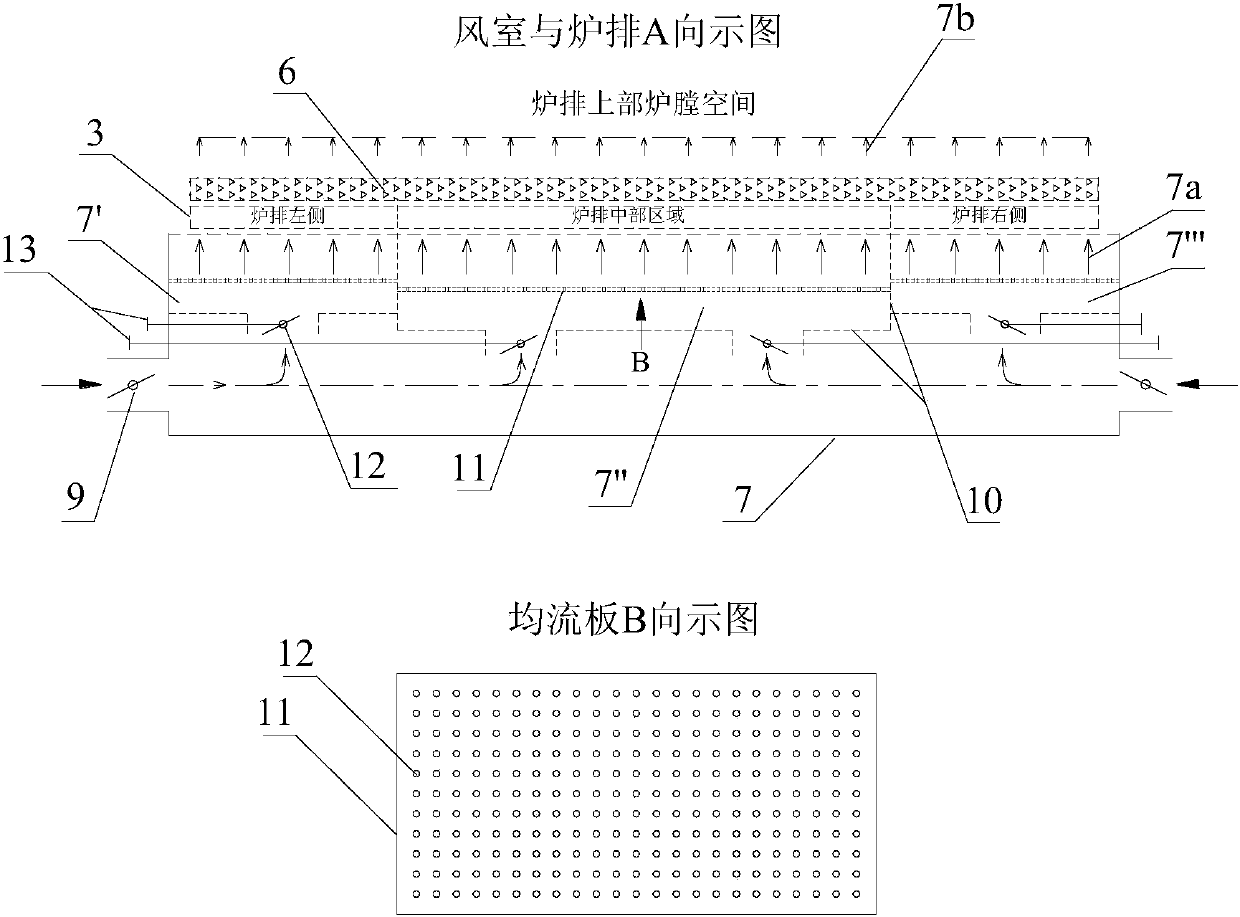

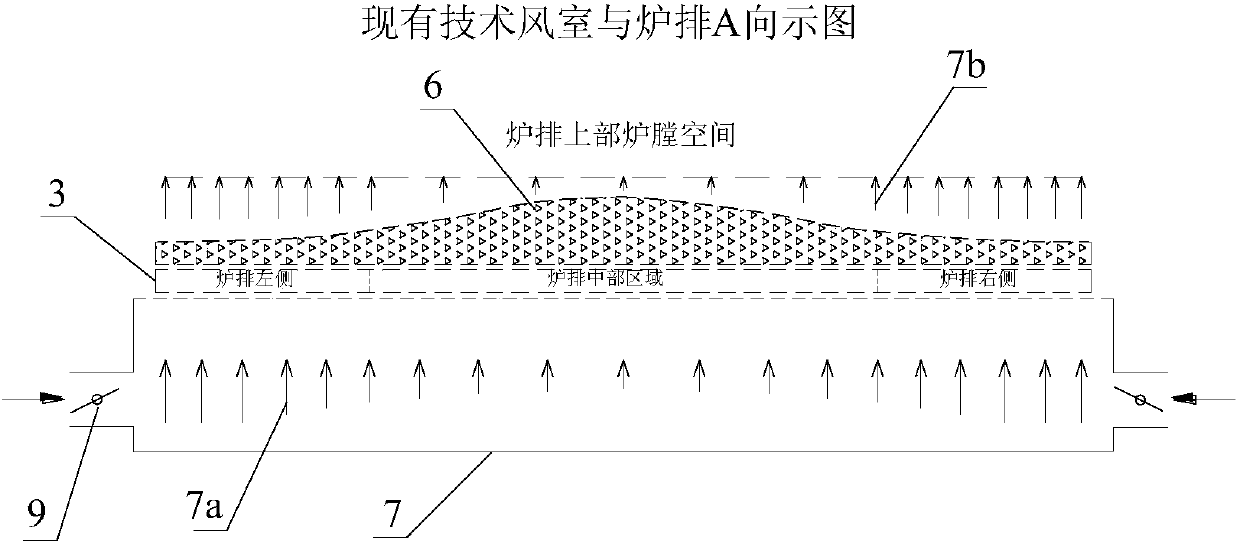

[0014] combine figure 1 and figure 2 Describe this embodiment, a low NO xHigh-efficiency chain furnace, the chain furnace is composed of furnace 1, coal feeder 2, fire grate 3, ash hopper 4 and slag hopper 5; the furnace 1 is composed of front furnace arch 1a, rear furnace arch 1b, front wall 1c, The rear wall 1d, the flame angle 1e and the furnace outlet 1f are composed, and the upper ends of the front furnace arch 1a and the rear furnace arch 1b are provided with waists to divide the furnace 1 into upper and lower parts; The coal feeder 2 provides a certain thickness of coal seam 6 on the fire grate 3, and the thickness of the coal seam 6 gradually becomes thinner due to the combustion process along with the direction of the fire grate 3; the space area wrapped by the fire grate 3 A plurality of primary air chambers 7 arranged in the shape of "one" are arranged, and the outlets of the plurality of primary air chambers 7 communicate with the fire grate 3, and the multiple...

Embodiment approach 2

[0018] combine figure 1 Describe this embodiment, when the low NO x When the high-efficiency chain furnace is a coal thrower chain furnace, the coal feeder 2 adopts the coal thrower 2 arranged on the side of the front wall 1c, and the coal particles are thrown to the rear wall 1d side by the coal thrower 2. A coal seam 6 is formed; the fire grate 3 is an inverted fire grate 3 traveling from the rear wall 1d side to the front wall 1c side; the furnace arch combination is such that only the front furnace arch 1a is provided without the rear Furnace arch 1b, but the layout scheme of the secondary air 8 adopts "the front furnace arch 1a arranges a plurality of the front arch secondary air nozzles 8a, and the lower part of the rear wall 1d arranges a plurality of the rear The secondary air nozzle 8b is arched. Other relevant furnace structure composition, air chamber structure layout and connection relationship are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com