Self-propelled marine visual grab bucket and sampling ship adopting same

A self-propelled, grab bucket technology, applied in the field of self-propelled marine visible grab bucket and its sampling vessel, can solve the problems of hydraulic system failure in the grab bucket, easy damage of the towing device, and impact by the sea current, etc. The ability of sea current impact, corrosion resistance, wear resistance, repeated retraction, good mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

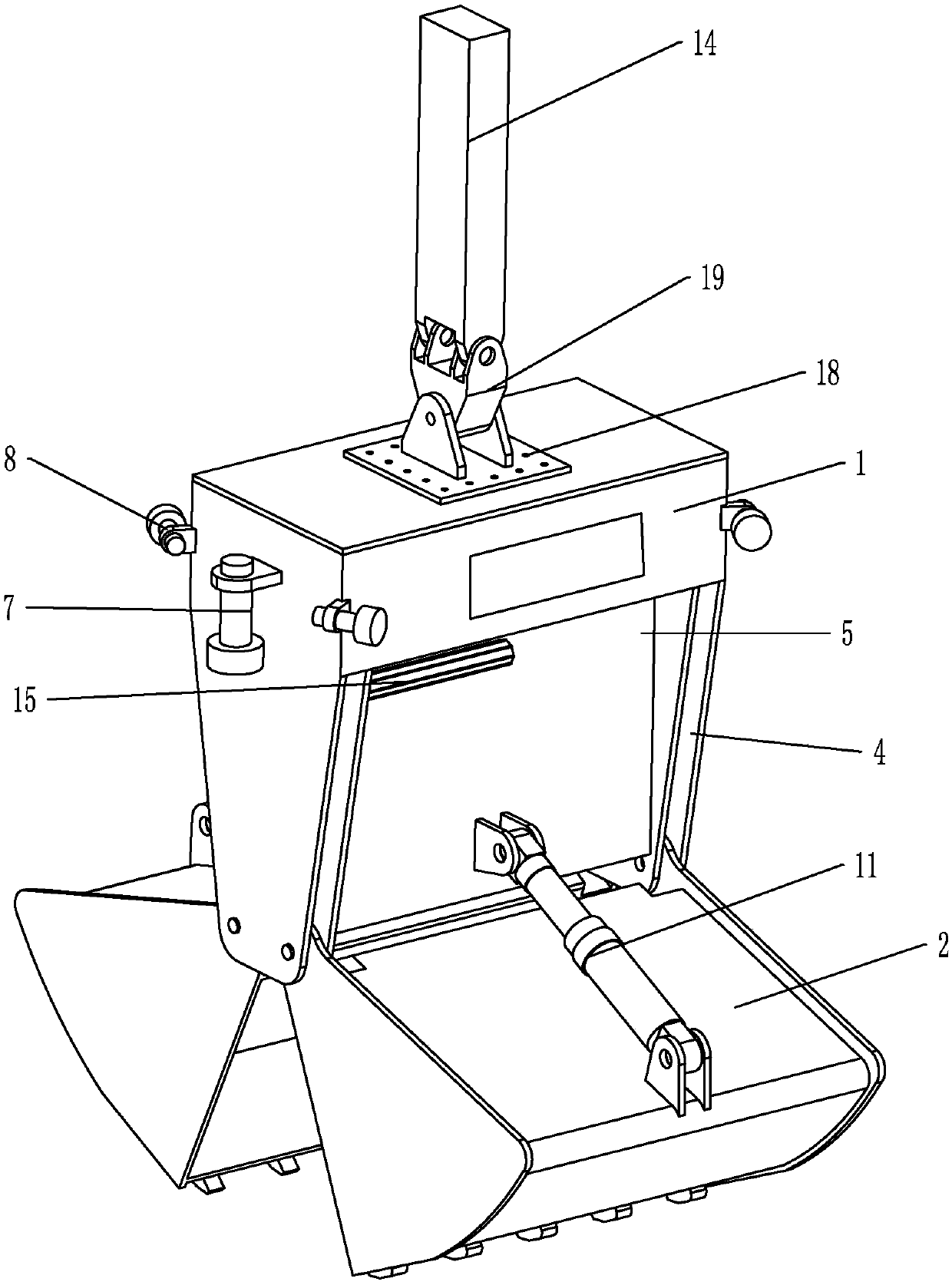

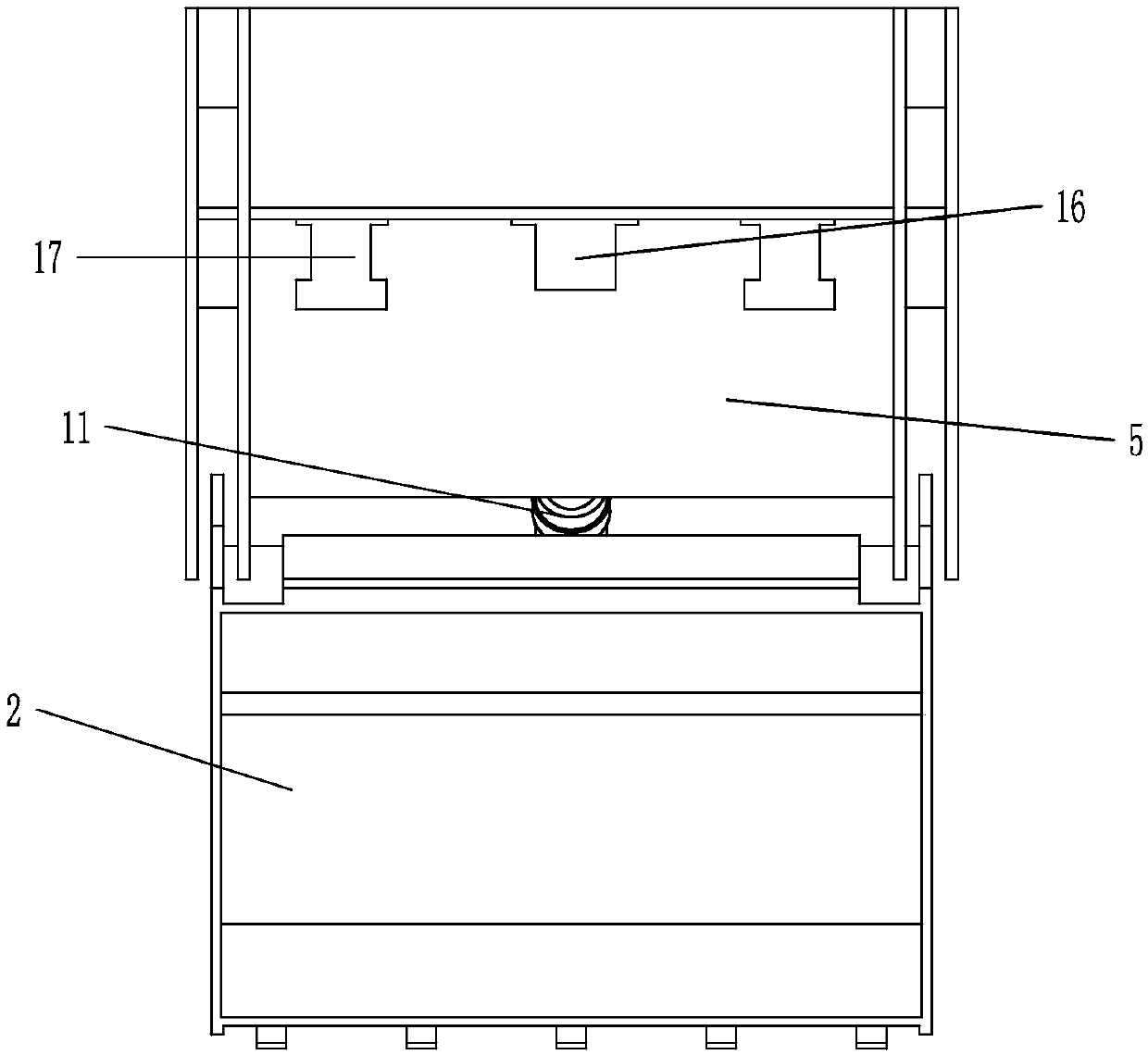

[0027] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

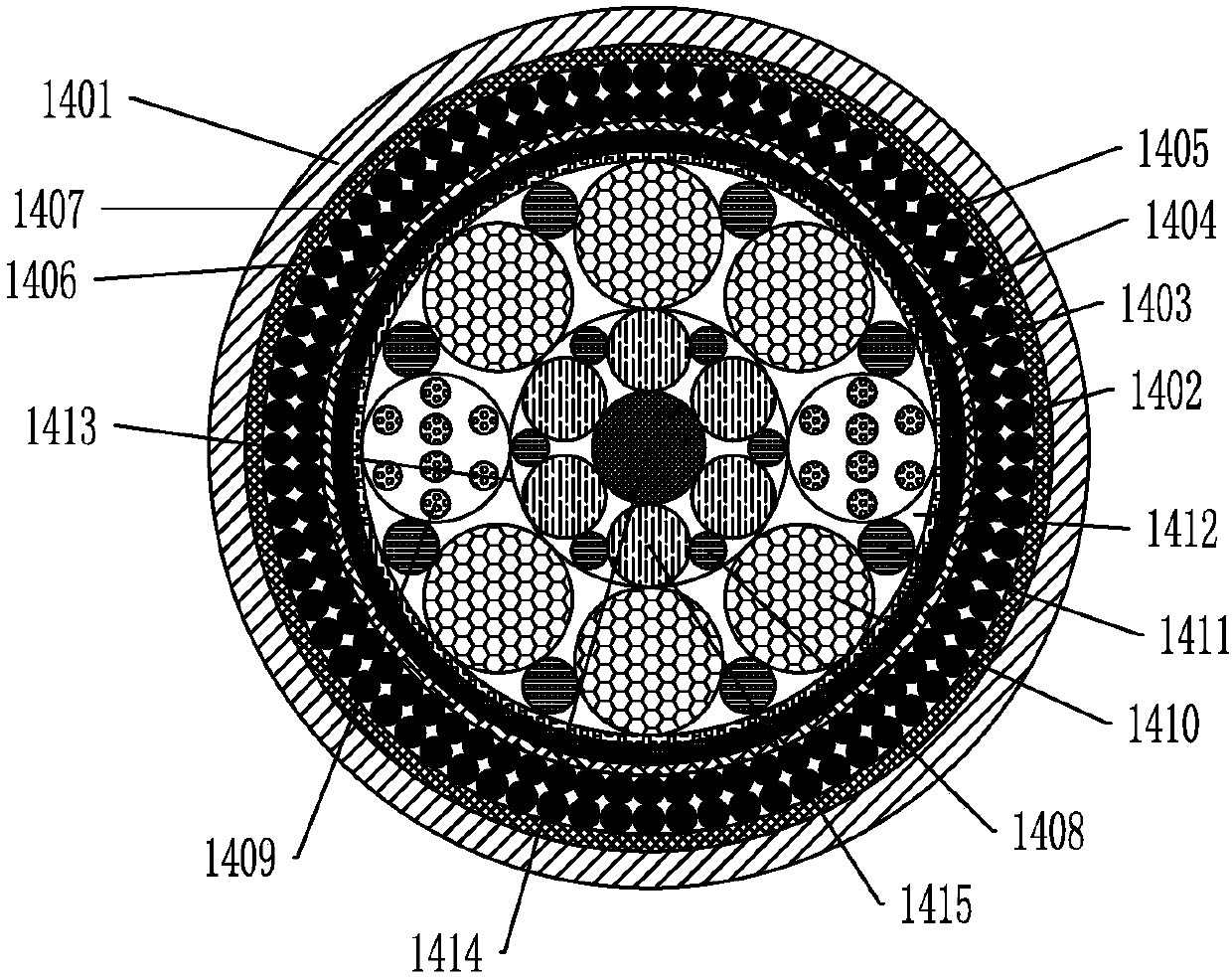

[0028] Such as Figure 1-6 As shown in , a self-propelled marine visible grab includes a grab installation main body 1 and two grab buckets 2 symmetrically hinged on the lower part of the grab installation main body 1. The upper part of the grab installation main body 1 is a sealed Two pairs of mounting lugs 4 are arranged opposite to each other on both sides of the bottom of the cabin 3 and the sealed cabin 3, and two installation base plates 5 are arranged in parallel between the two pairs of grabbing bucket mounting lugs 4; The ear plate 4 is hinged, and the tops of the two grabs 2 are respectively hinged with the installation base plate 5 through a grab opening and closing hydraulic cylinder 6;

[0029] Two relative outer walls of the sealed cabin 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com