Arrangement type terminal crimping auxiliary device

A terminal crimping and auxiliary device technology, applied in the direction of connection, circuit/collector parts, electrical components, etc., can solve the problems of hidden safety hazards, easy injury and fingers, and low daily output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

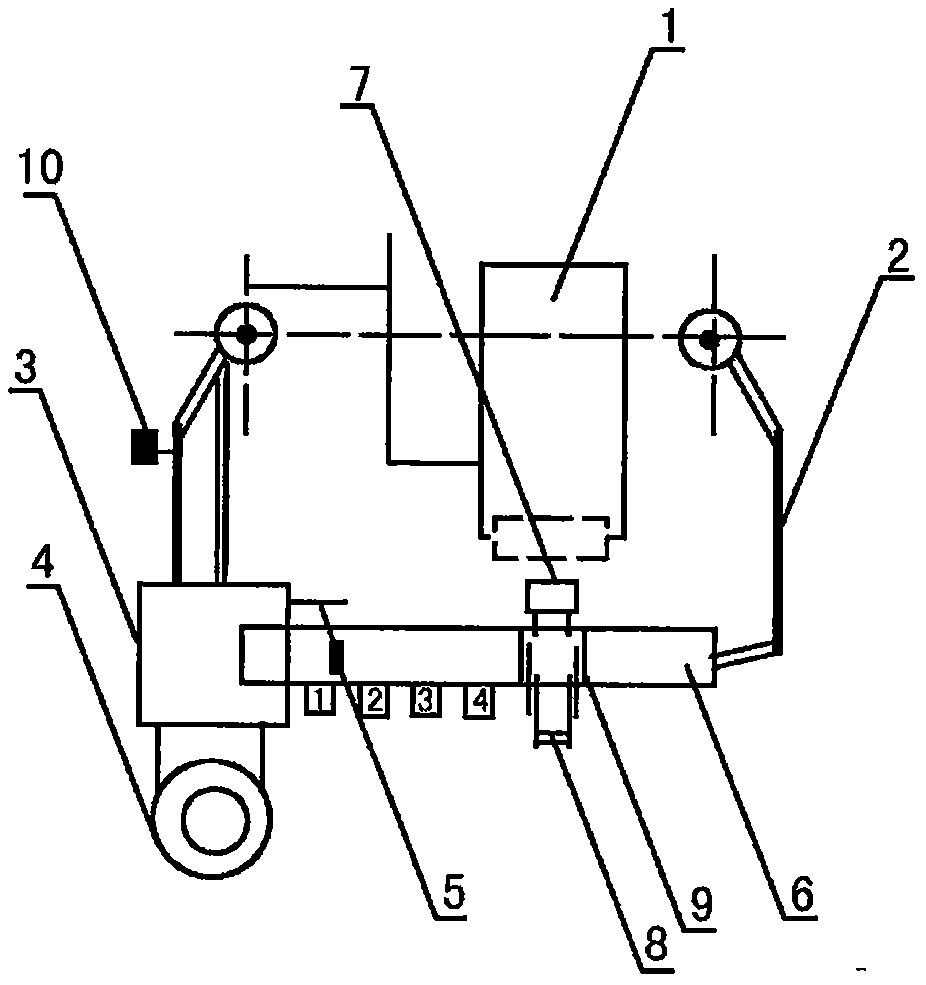

[0012] Embodiment: as shown in the accompanying drawing. A wire-type terminal crimping auxiliary device, including a semi-automatic crimping machine body (1), with suspended support arms (2) arranged on both sides of the body (1) die, the height of which is positioned flush with the delivery port, and the front end The cable arrangement structure includes a terminal storage compartment (3), a wire support device (4), a single distribution device (5), a horizontal cable trough (6), a copper wire measuring device (7) located in front of the delivery port, and a The push handle (8) and the sliding bracket (9). When in use, the wire harness is placed in the storage compartment (3) for automatic separation. The operator only needs to move the push handle (8) to carry out the crimping operation.

[0013] The utility model relates to an auxiliary device for crimping a cable-type terminal, which is provided with a prompting device (10), which sends a corresponding prompt when the leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com