Micro element feeder

A technology of micro-components and feeders, applied in the direction of electrical components, electrical components, etc., can solve the problems of expensive products, side-standing materials, poor feeding, etc., to ensure stability and stability, ensure feeding stability, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

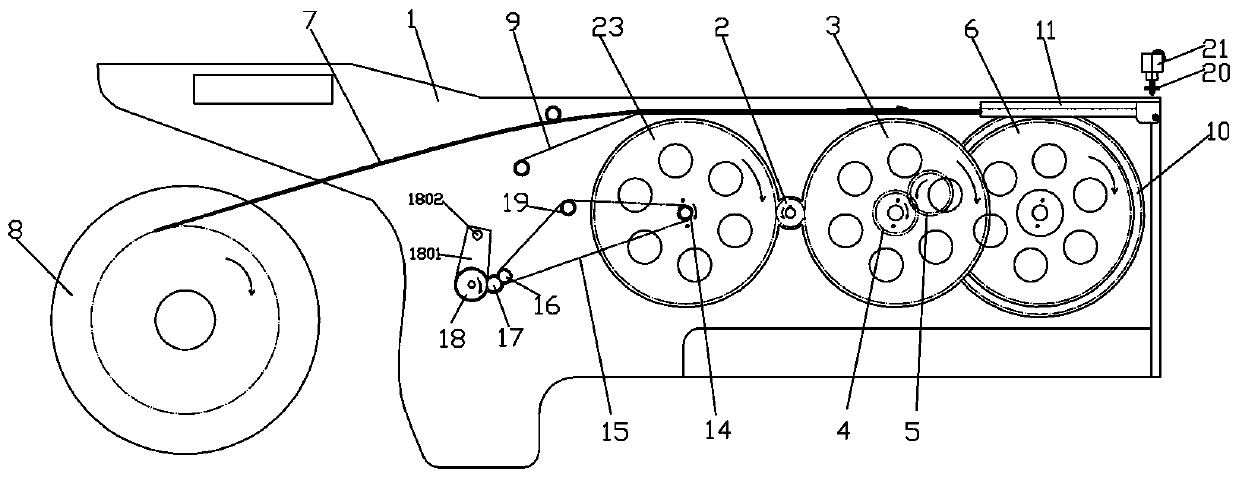

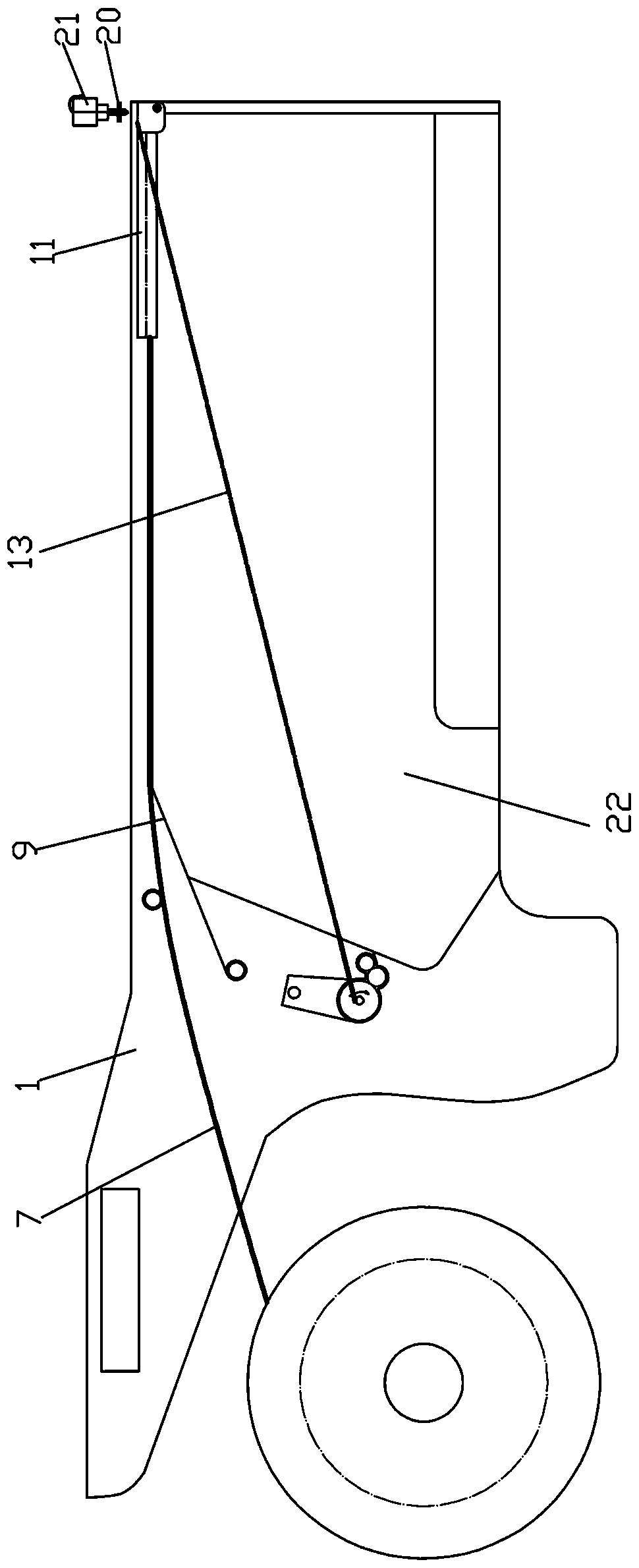

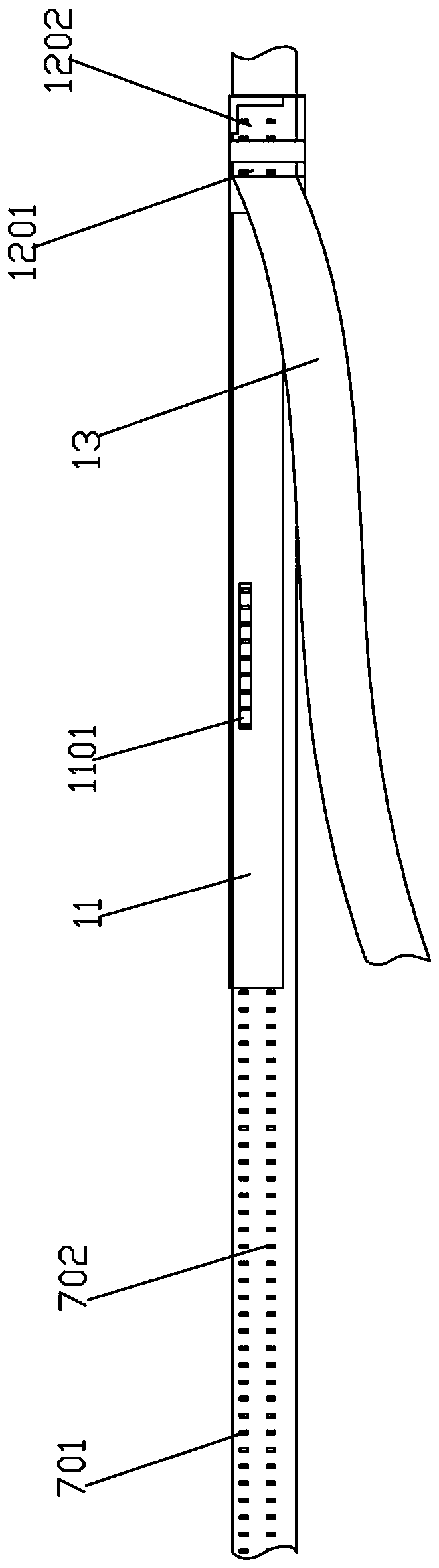

[0023] Below in conjunction with accompanying drawing and present embodiment the present invention is further described:

[0024] see Figure 1-4 .

[0025] The invention discloses a micro-component feeder, which includes a housing 1, and a conveying paper belt 7 for transferring micro-components is arranged on the upper side of the housing 1. The support plate 9 extending in the direction is used to support the conveying paper belt. One side of the housing 1 is provided with a material rack 8 for installing a paper roll. The conveying paper belt 7 is disc-shaped and wound on the material rack 8 On the rotating shaft in the middle, after the paper roll is installed on the material rack 8, one end of the conveying paper belt 7 is pulled out and placed on the support plate 9, and a row of conveying holes 701 and a row of miniature The placement groove 702 of the component, the miniature components are installed in the placement groove 702 one by one, and the transmission holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com